Slot screen branching caulking groove positioning and welding device

A positioning welding and screen technology, which is applied in welding equipment, roller electrode welding, resistance welding equipment, etc., can solve the problems that the gap precision of the screen bar and the flatness of the screen surface are difficult to meet the use requirements, and achieve positioning welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

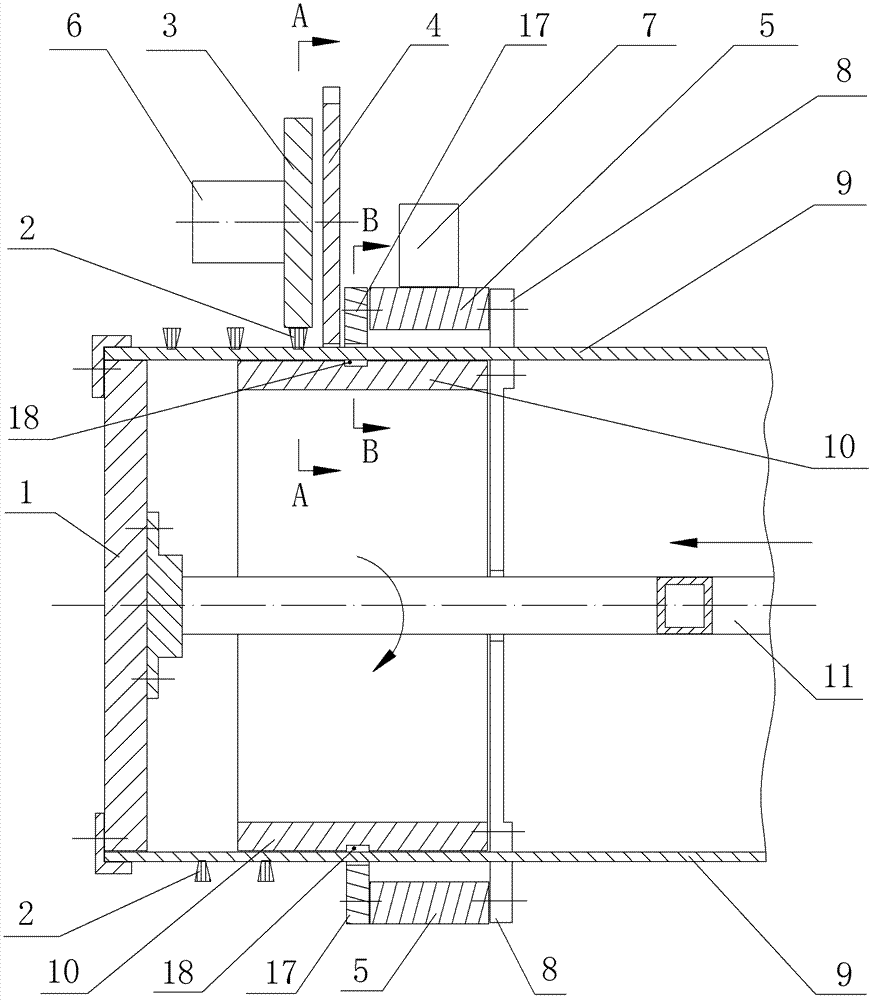

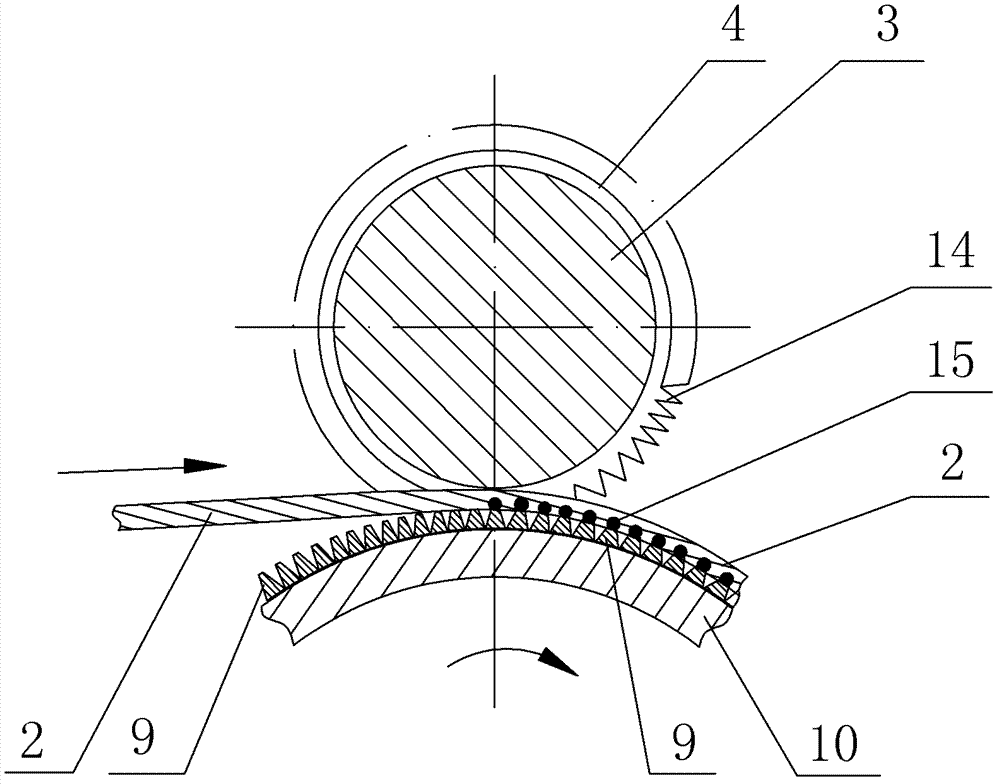

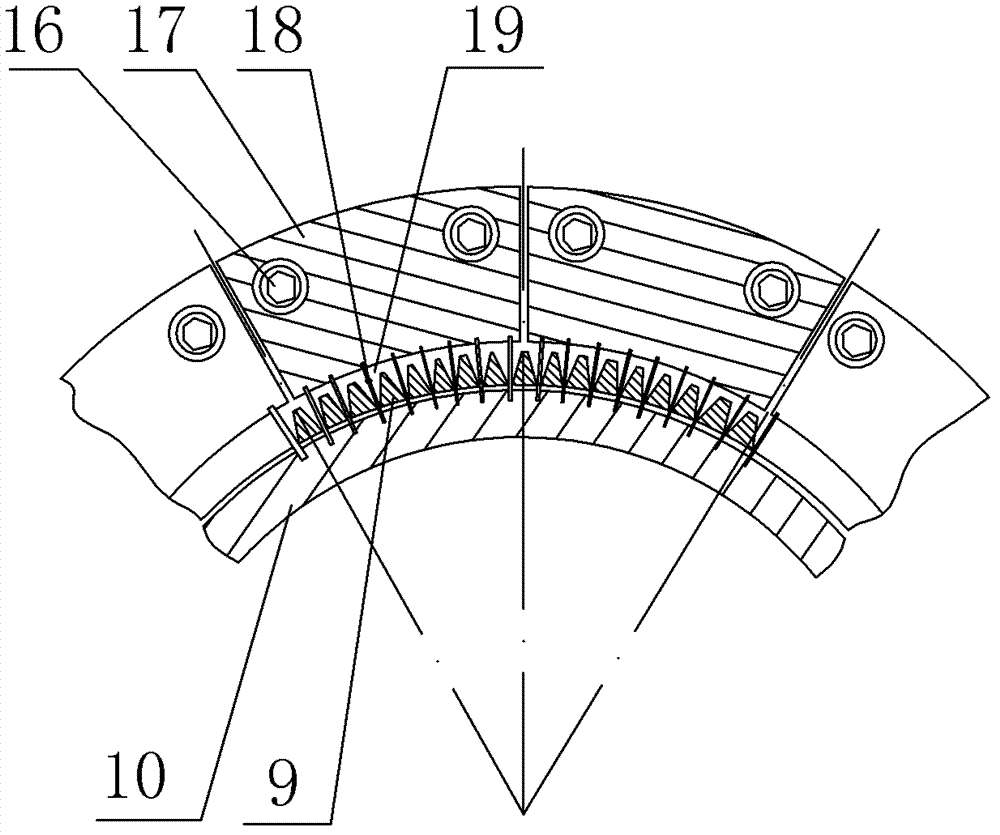

[0014] Such as figure 1 , figure 2 , image 3 As shown, the slit screen is divided into slotted positioning welding devices, which include welding wheel 3, slotted gear 4, comb tooth ring seat 5, positive electrode brush 6, negative electrode brush 7, I-shaped connection block 8, and wire mesh bed 10. There are through holes in the screen bed 10 (the screen bed 10 is a cylindrical structure), and 100 to 10,000 screen wires 9 are evenly arranged on the outer circumference of the screen bed 10 (the specific number depends on the required slit screen. The size is determined), the left end of the screen wire 9 is fixed to the left disc 1, the right end of the screen wire 9 is fixed to the right disc, the left end of the shaft 11 is fixed to the left disc 1, and the right end of the shaft 11 passes through the passage of the screen bed 10 The hole is fixed with the right disc (the left disc 1 or the right disc is connected with a mechanism that both rotates and moves linearly, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com