Method for artificially sealing cans of synthetic paper cans

A technology for sealing cans and paper cans, applied in the field of false sealing of synthetic paper cans, can solve the problems such as the inability to obtain the expected effect and yield of false roll sealing, and the inconsistency of operating costs, and achieve the effect of low cost and high process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

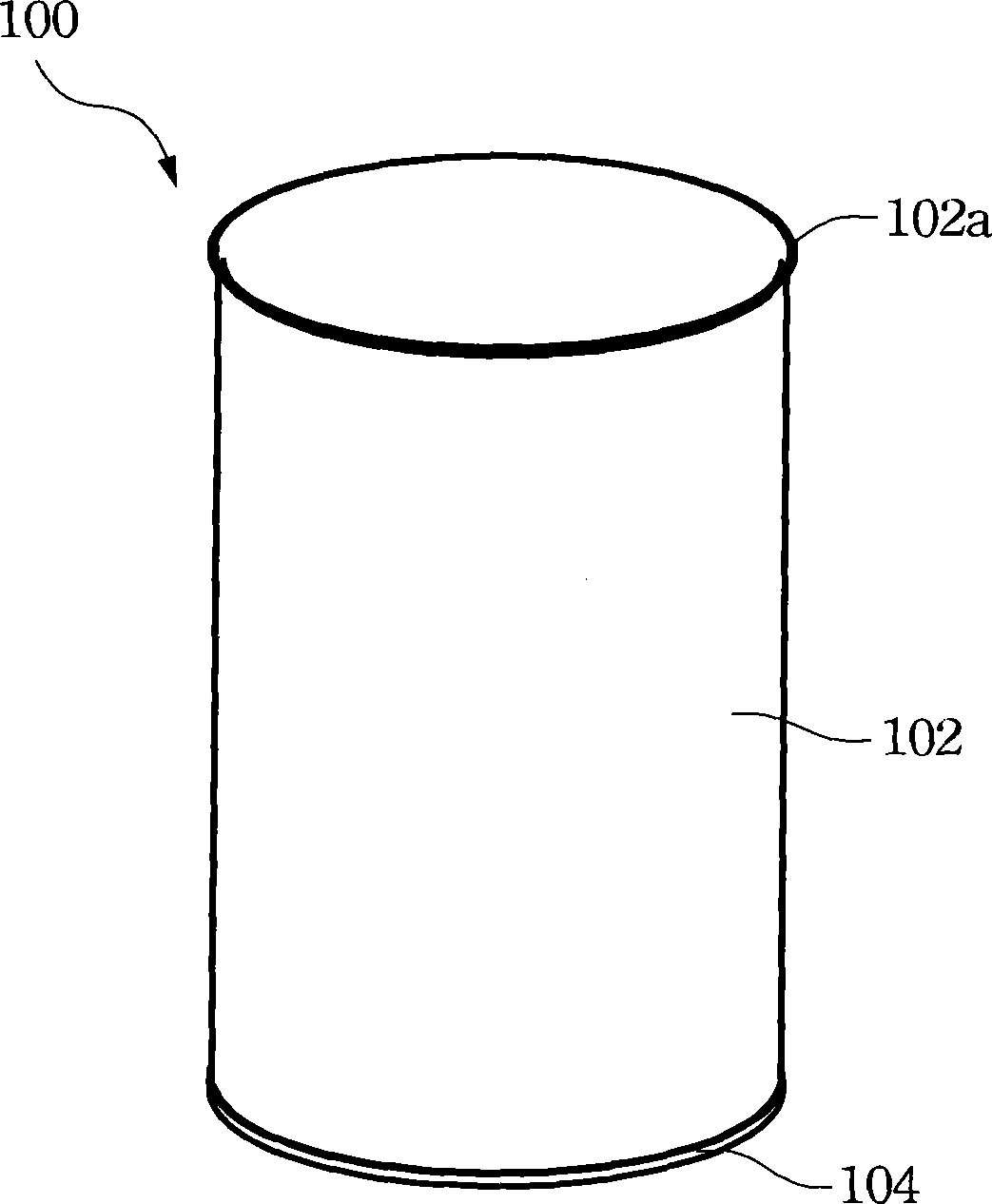

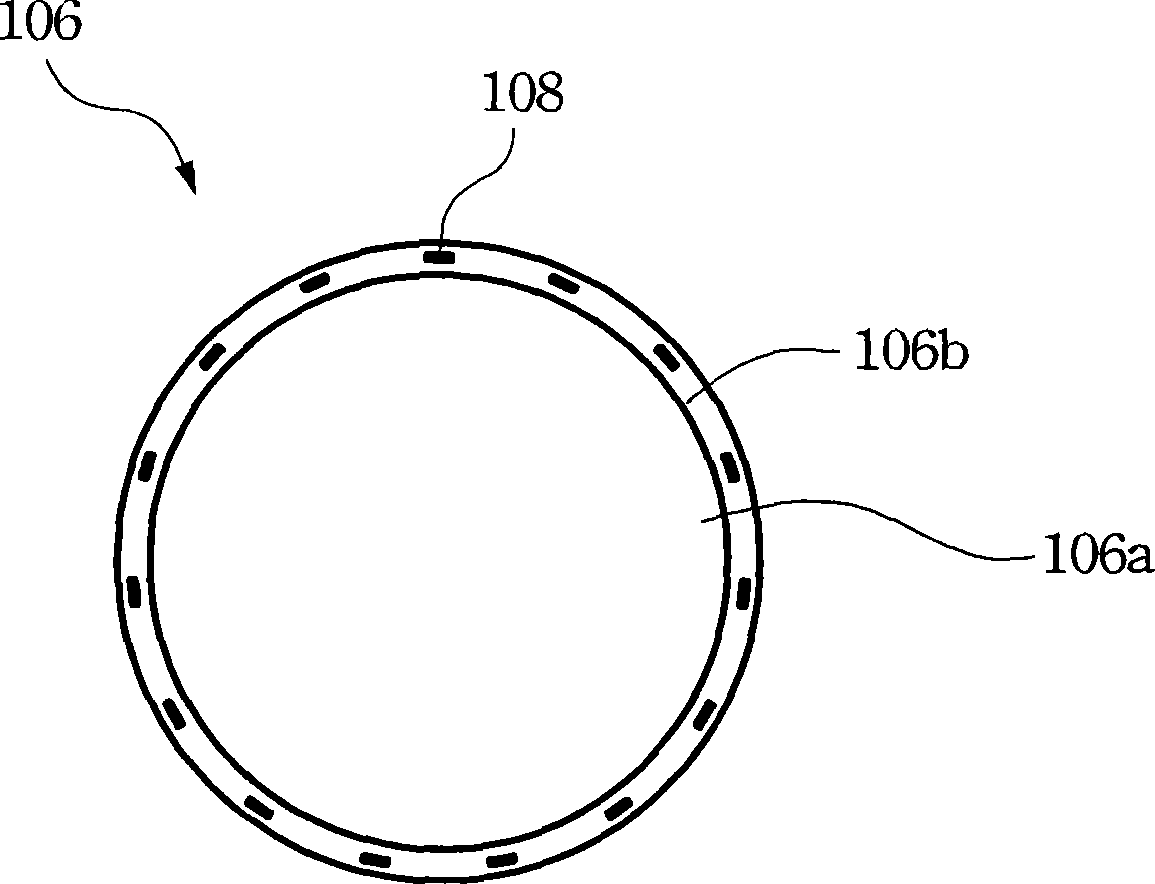

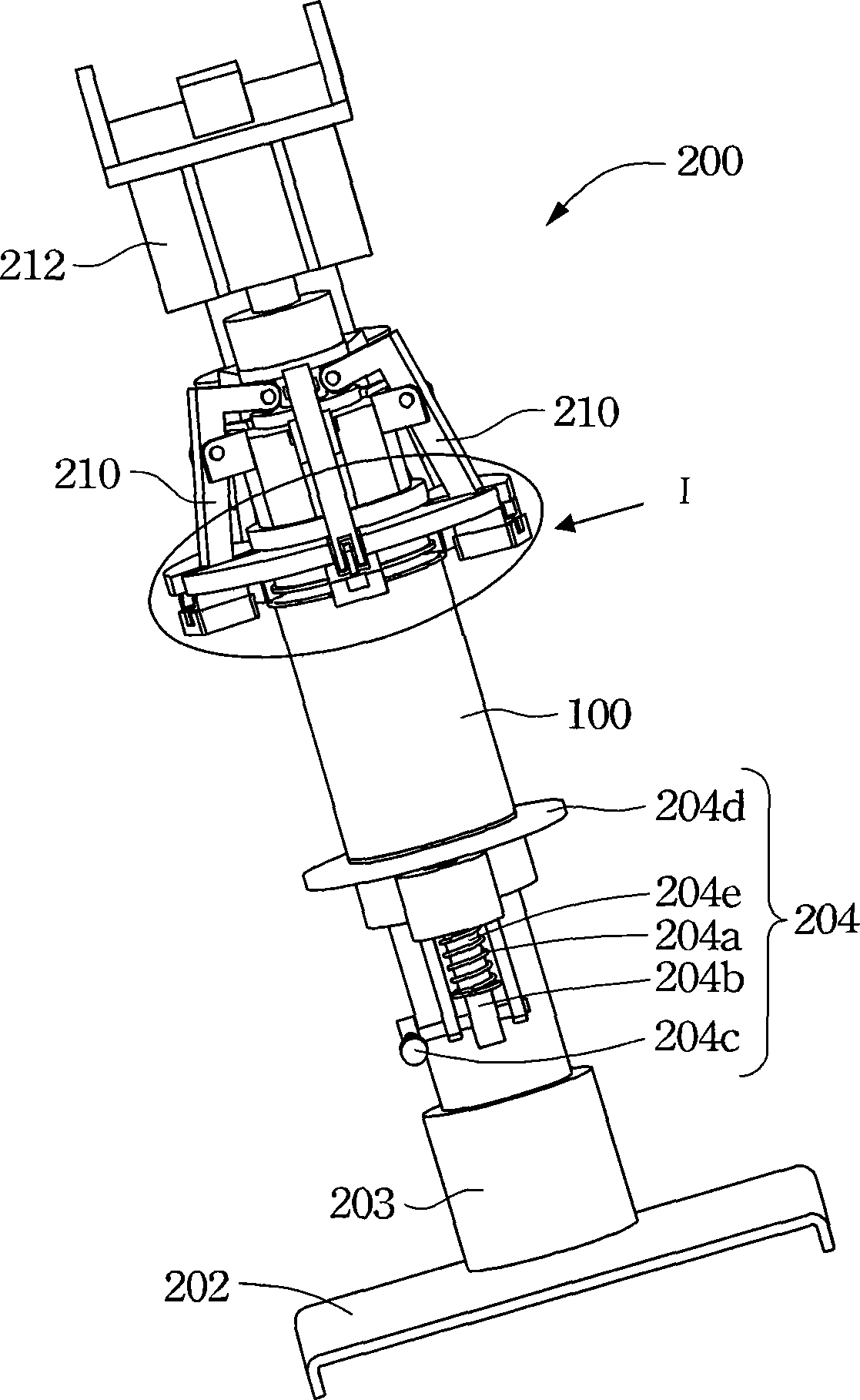

[0021] Please refer to figure 1 , which is a synthetic paper can according to a preferred embodiment of the present invention. figure 2 It is a can sealing lid according to a preferred embodiment of the present invention. The invention provides a sealing device and method for a synthetic paper can, so that the synthetic paper can can be easily introduced into a process of vacuuming or nitrogen filling. The so-called "synthetic paper cans" refer to cans with cardboard as the main support material. The more commonly used "synthetic paper cans" are made of paper, polymer materials and metal foil. Before the can body 102 of the synthetic paper can 100 is sealed, the rim 102 a at the top of the can body 102 needs to be curled outward first, and then the seaming lid 106 is placed on the curled can rim 102 a. The bottom end of the tank body 102 is sealed with a sealing lid 104 earlier. When vacuumizing or nitrogen-filling the synthetic paper can, the can sealing lid 106 needs to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com