Coupling capacitor-affected dummy metal filling method for chemical mechanical polishing process

A technology of coupling capacitors and metal filling, which is applied to electrical components, circuits, electrical digital data processing, etc., can solve the problems of compromise between accuracy and calculation speed, and the inability to balance speed and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

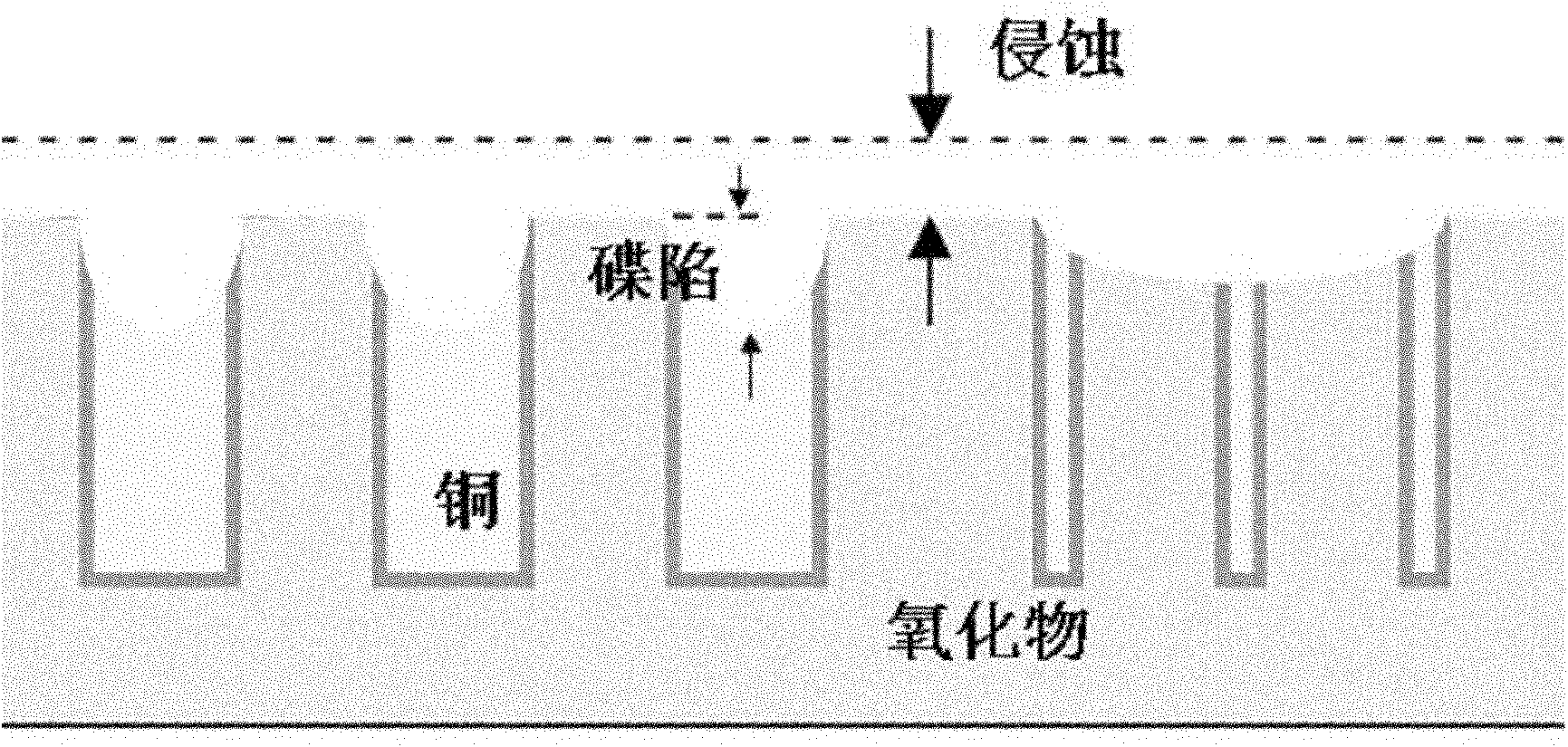

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110] In order to make the objects, features and advantages of the present invention more obvious and understandable, the present invention will be further described below through specific examples.

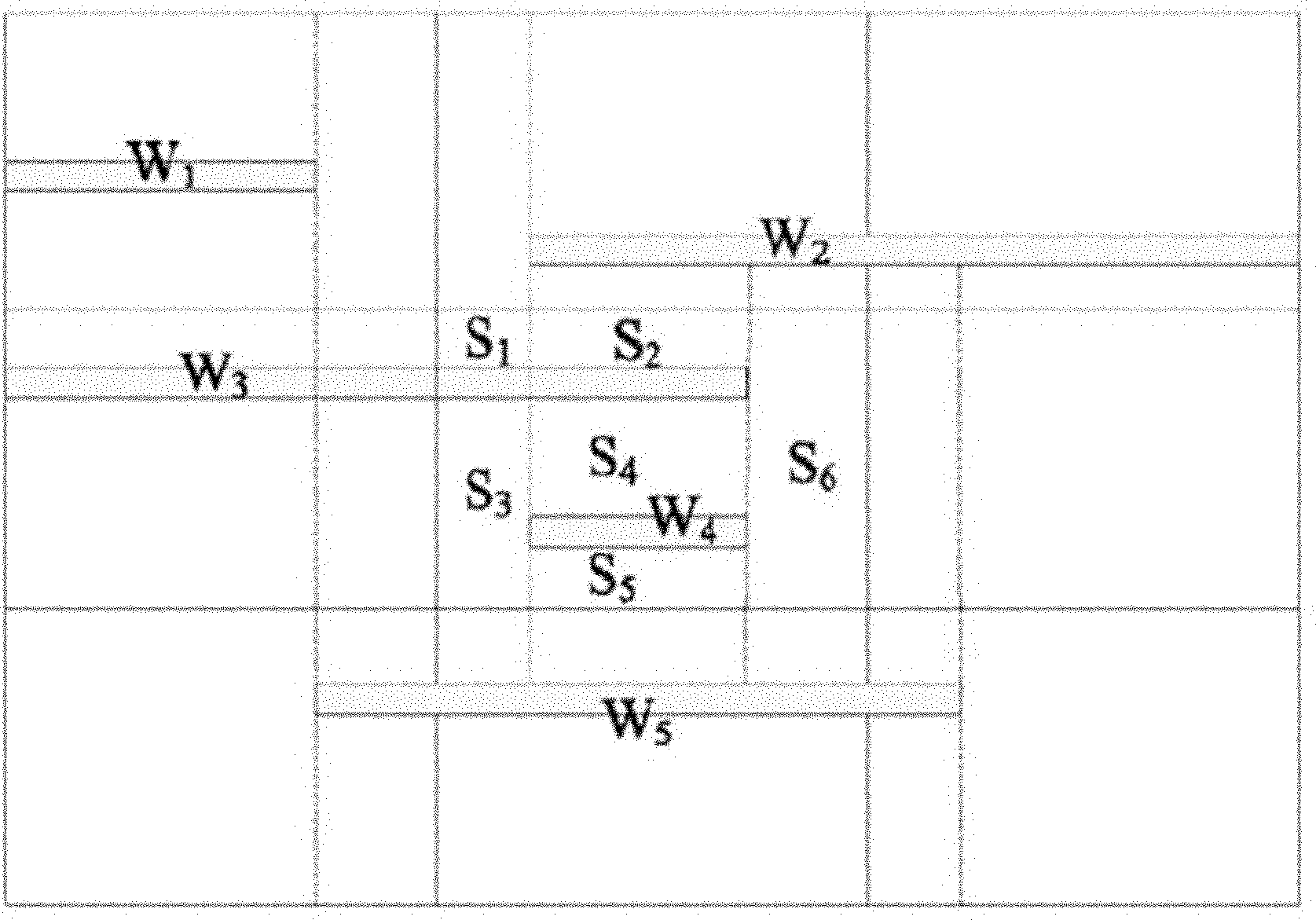

[0111] This part of the experiment is to verify the effectiveness of the dummy metal filling approximation algorithm proposed in this paper to minimize the influence of coupling capacitance. Experimental test cases are from [12] and are also available at the Collaborative Benchmarking Laboratory (CBL). The layout information of the experimental test is shown in Table 1, and "#Wire" in the table indicates the number of information line segments in the layout.

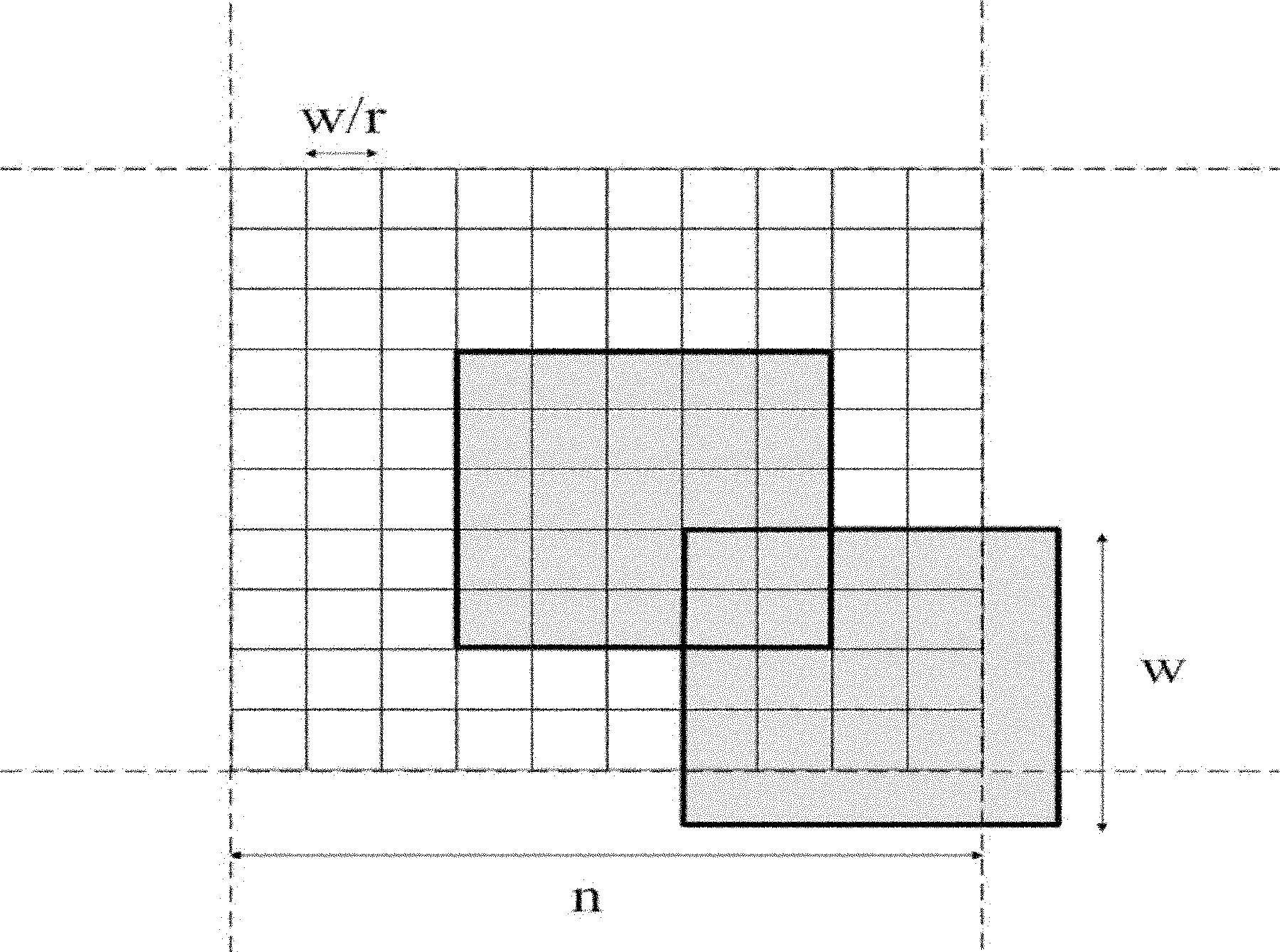

[0112] Applying the complete polynomial time approximation algorithm FPTAS proposed by the present invention to obtain the result of dummy metal filling, at first need to carry out fixed r-division to the whole layout, in this embodiment r=3, adopt the filling pattern of rectangular small metal block here, and assume that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com