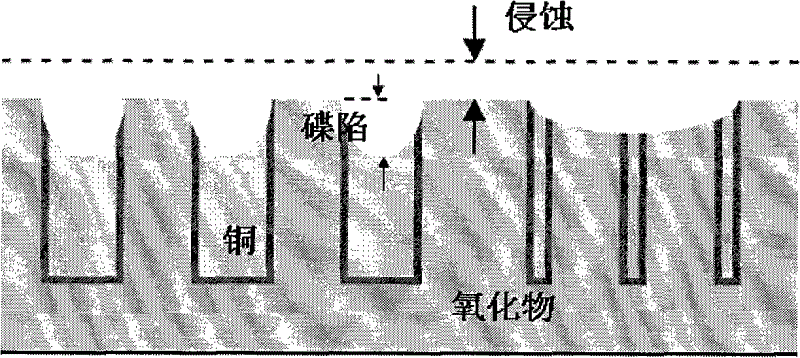

Dummy filling method of chemical-mechanical polishing process

A technology of chemical mechanics and filling methods, which is applied in the fields of instruments, calculations, electrical digital data processing, etc., and can solve problems such as the compromise between accuracy and calculation speed, and the inability to balance speed and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

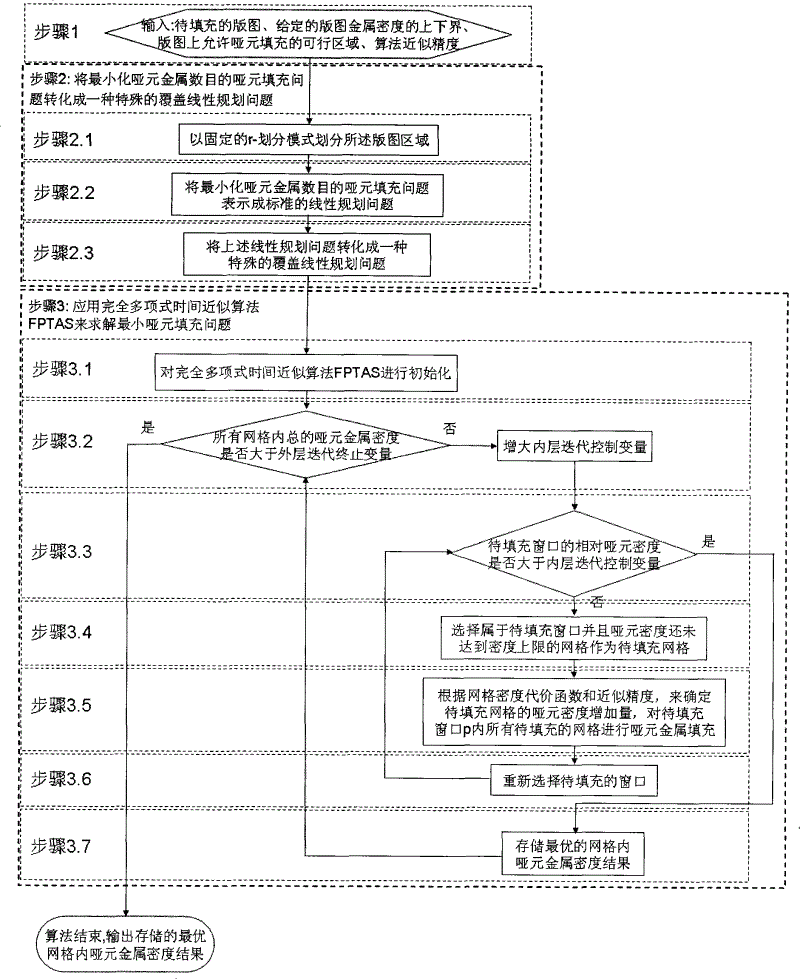

Method used

Image

Examples

Embodiment Construction

[0099] In order to make the above objects, features and advantages of the present invention more obvious and understandable, the present invention will be further described below through specific examples.

[0100] The first embodiment of the present invention is used to test the feasibility of the method of the present invention. In this embodiment, the input is a layout after FPGA layout and wiring, the size is 854um*243um, and there are 202238 interconnected metal patterns on the layout. In this embodiment, the layout is enlarged by 3 times as it is and used as the input layout. Finally, it is required that the metal density range of the layout after dummy metal filling is L=0.4 to U=0.5.

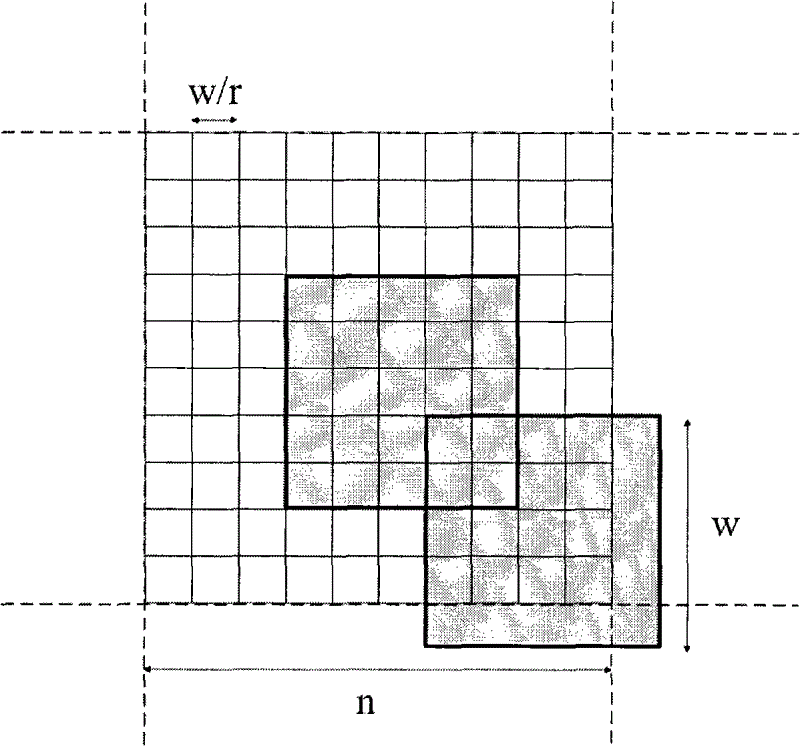

[0101] We apply the complete polynomial time approximation algorithm FPTAS proposed by the present invention to obtain the result of dummy metal filling. First, we need to carry out fixed r-division of the entire layout. In this embodiment, r=5, and the size of the floating window is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com