Synchronous motor of solid pole winding with damp

A technology of synchronous motor and damping winding, which is applied in the direction of synchronous motor for single-phase current, etc., to achieve the effect of obvious effect, simple structure and expansion of use range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

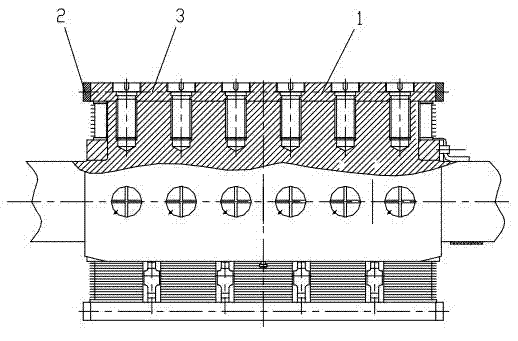

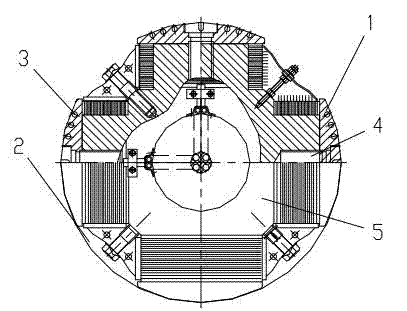

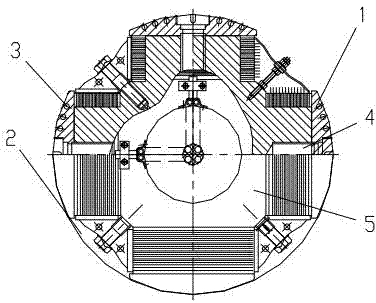

[0012] In order to further understand the features and technical content of the present invention, please refer to the following detailed description and drawings related to the present invention. However, the drawings are provided for reference and illustration only, and are not intended to limit the present invention.

[0013] Such as figure 1 , figure 2 As shown, the main components of the synchronous motor rotor of the present invention include pole shoe 1 , damping ring 2 , damping strip 3 , high-strength connecting bolt 4 and pole body (with shaft) 5 .

[0014] from figure 1 It can be seen that a hole is processed in the pole piece 1 of the solid magnetic pole, and a damping strip 3 is pierced in the hole, and the damping strip 3 is short-circuited at the end with a damping ring 2 to form a full damping winding.

[0015] from figure 2 It can be seen that in the present invention, a hole for placing the damping strip 3 is opened on each pole shoe 1 according to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com