Glass flush door and production method thereof

A plane and glass technology, applied in the direction of door leaves, etc., can solve the problems of limited size of door frame, high cost of door frame, difficult to realize, etc., and achieve the effect of reducing production cost and overall beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

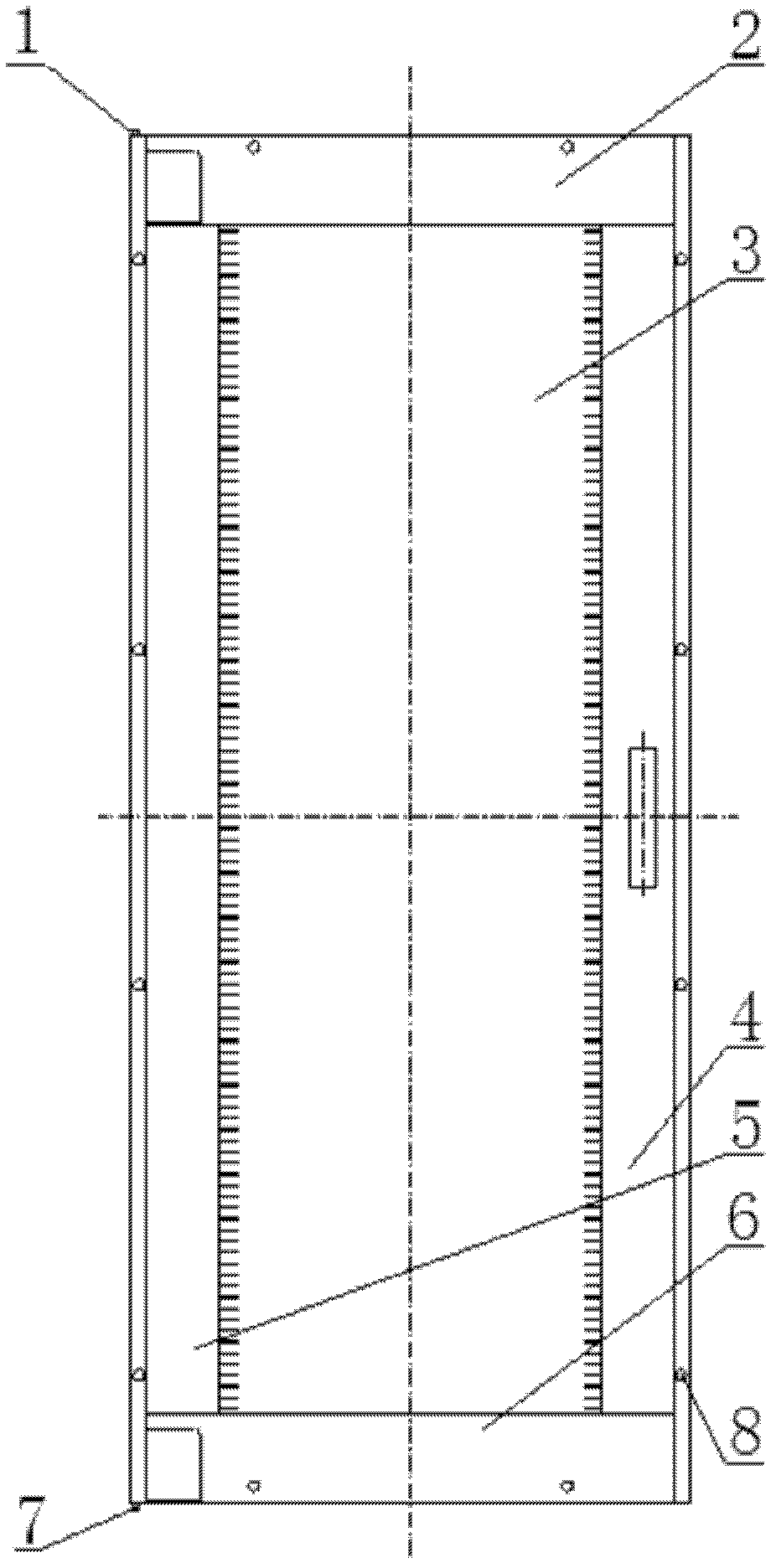

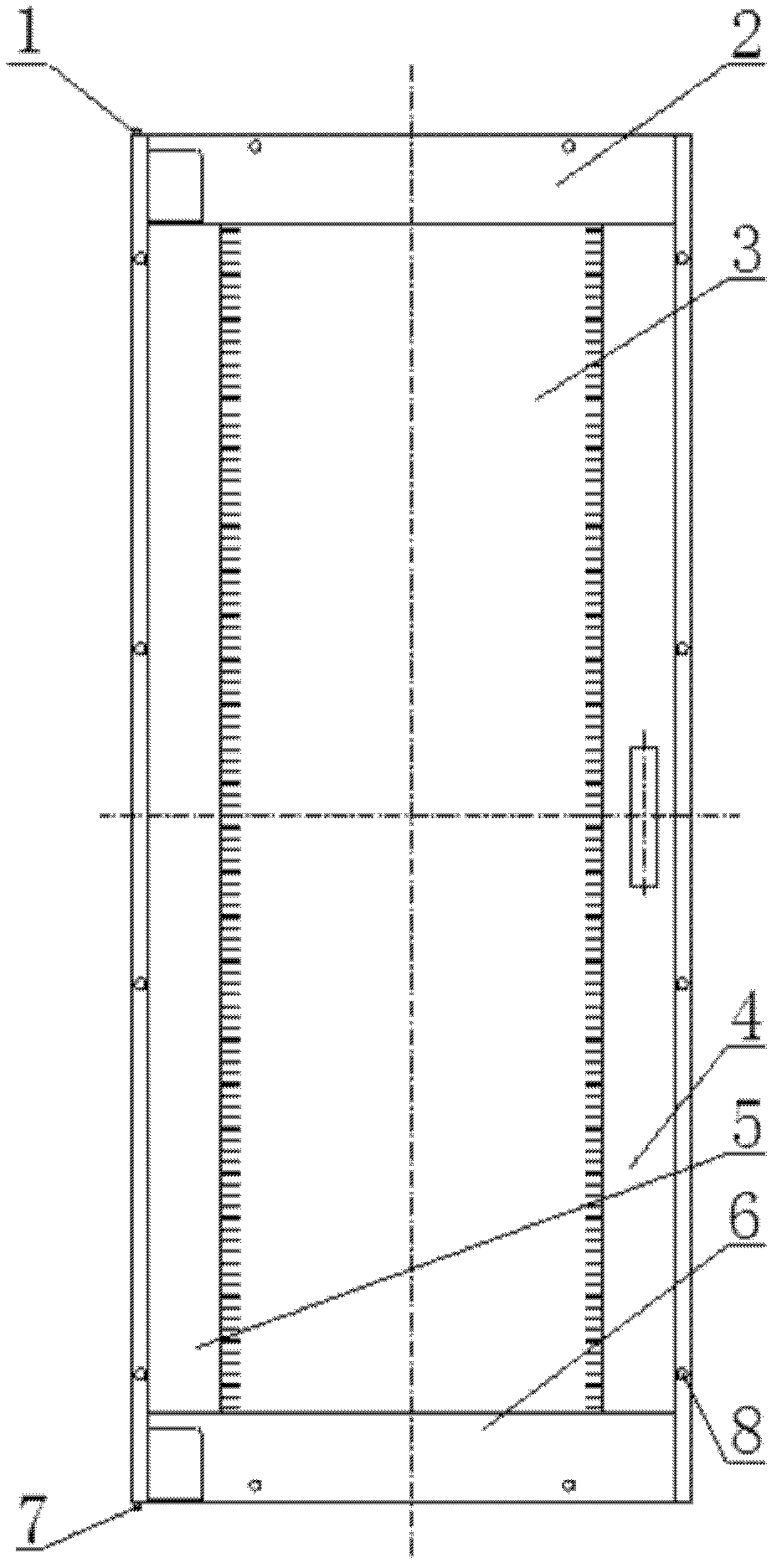

[0021] figure 1 It is a structural schematic diagram of the present invention, this kind of glass planar door comprises the rectangular door frame that is made up of door frame upper baffle plate 2, door frame lower baffle plate 6, lock door side 4 and hinge door side 5, a surface of toughened glass 3 is pasted on the door frame On the other hand, the height of the other surface of the tempered glass 3 opposite to the sticking surface is on the same plane as the door frame, or is lower than the plane where the door frame is.

[0022] One end of the hinged door side 5 is provided with an upper door pin 1, and the other end is provided with a lower door pin 7; the folds on the locked door side 4 and the hinged door side 5 are greater than or equal to 12 mm; the upper door frame baffle 2, the door frame lower baffle 6. The lockable door side 4 and the hinged door side 5 are fixed together by welding, and the upper baffle 2 of the door frame and the lower baffle 6 of the door fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com