Liquid level display device, container using same and engineering plant

A liquid level display and container technology, which is used in buoy liquid level indicators, liquid level indicators, lubrication indicating devices, etc., can solve the problems of inability to visually detect liquids, inconvenient movement of construction personnel, and dim construction environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

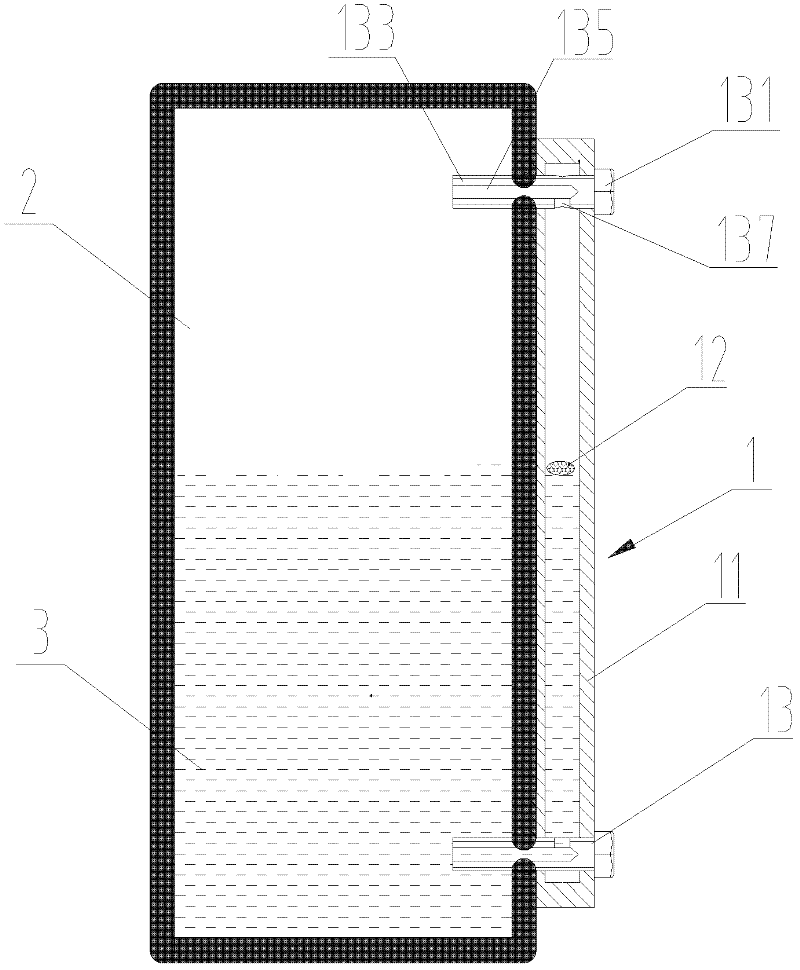

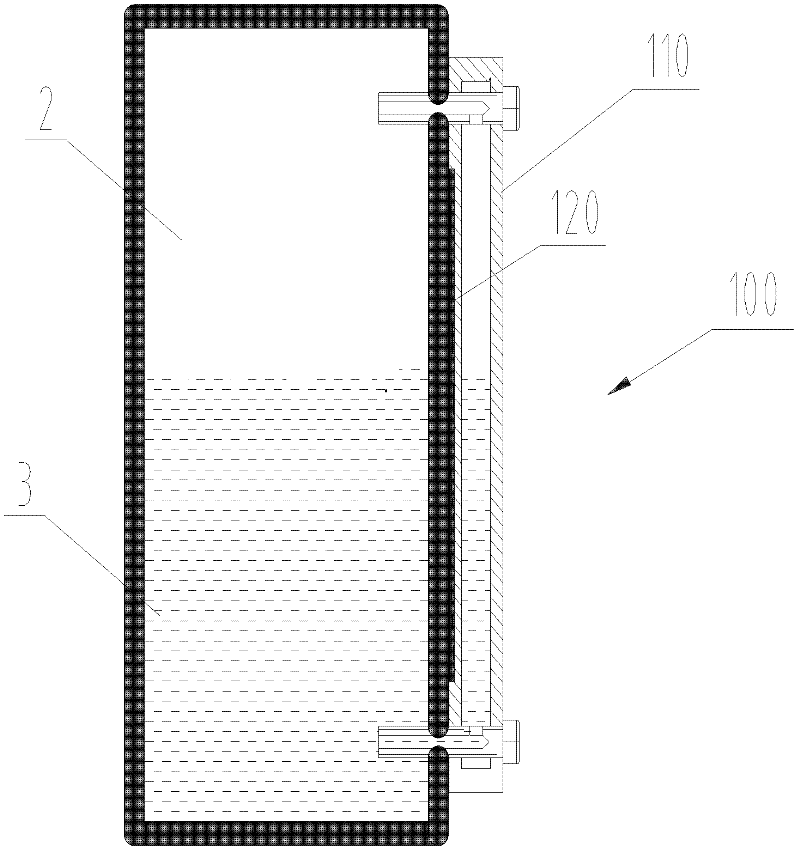

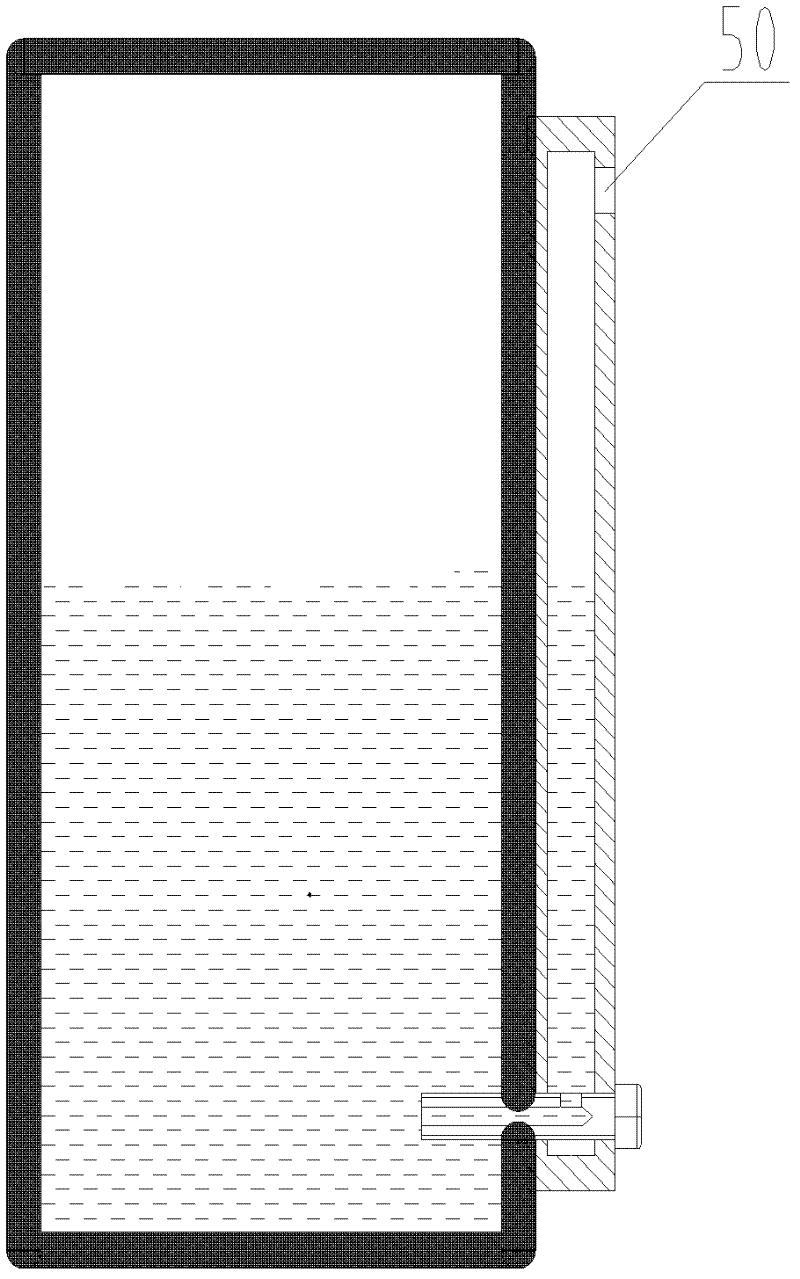

[0022] Below will combine the preferred embodiment of the present invention figure 1 and figure 2 , clearly and completely describe the technical solutions in the embodiments of the present invention.

[0023] see figure 1 , the present invention provides a liquid level display device 1, which is applied to a container 2 to roughly measure the liquid level of the liquid 3 in the container 2.

[0024] The liquid level display device 1 of the first preferred embodiment of the present invention includes a tube body 11 , a photosensitive element 12 and a connecting element 13 .

[0025] The tube body 11 is roughly in the shape of a hollow tube, which is made of transparent materials, such as glass, plexiglass and the like. The tube body 11 is used to contain the liquid 3 in the container 2 and the photosensitive element 12 . The inside of the tube body 11 is provided with a cavity for accommodating the liquid, and two through holes (not shown in the figure) are respectively o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com