Buffer device for fully-closed dehydration pipeline of oil tank

A technology of buffer devices and dehydration pipes, which is applied in the direction of distribution devices, special distribution devices, liquid distribution, transportation or transfer devices, etc., and can solve problems such as sludge blockage, limited liquid flow, and oil passages that cannot meet the requirements of continuous and effective dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

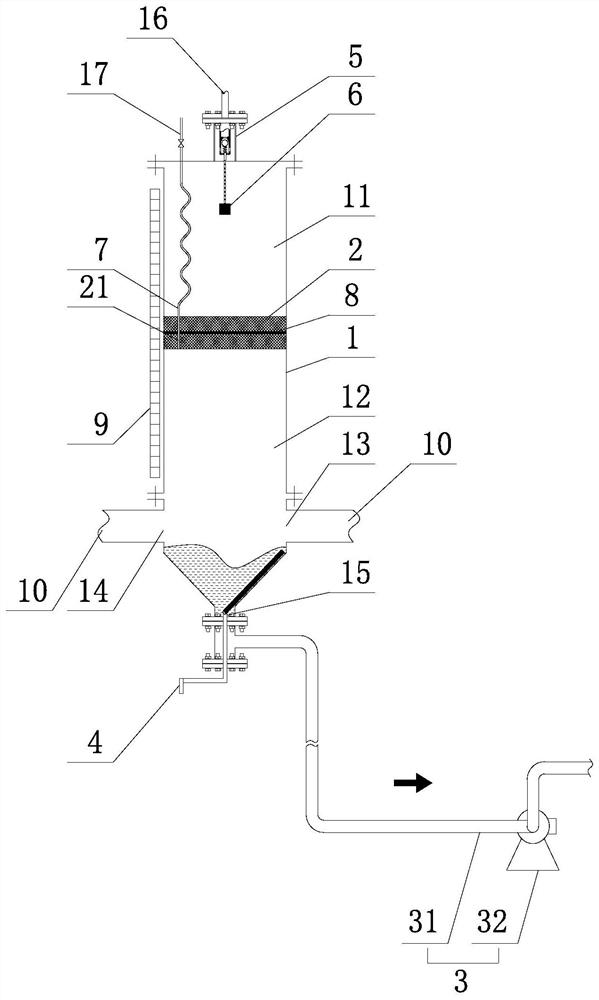

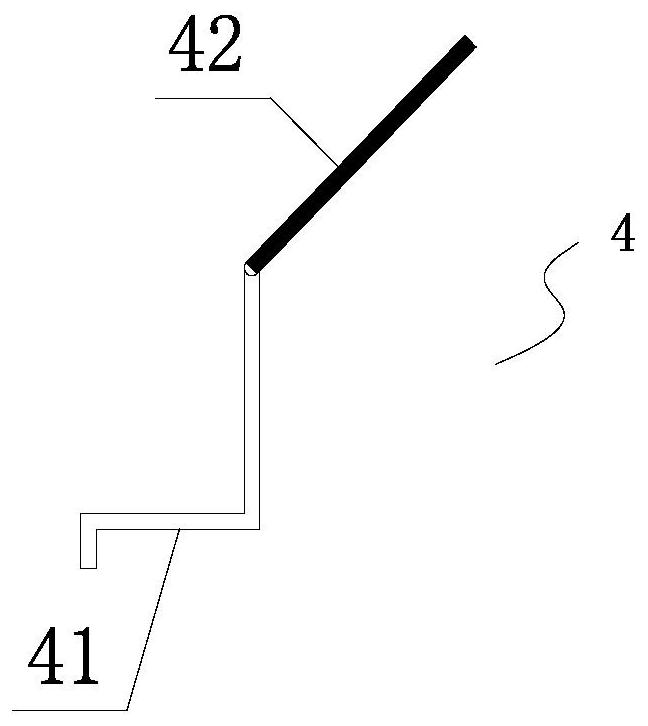

[0028] Such as figure 1 , figure 2 As shown, a buffer device for a fully enclosed dehydration pipeline of an oil tank according to the present invention includes a buffer tank 1 connected to a fully enclosed dehydration pipeline 10 of an oil tank. surface and divide the interior of the buffer tank 1 into upper and lower two independent areas of the sealing partition 2, the sealing partition 2 divides the interior of the buffer tank 1 into an upper buffer zone 11 and a lower liquid storage area 12, and the buffer tank 1 The side walls of the lower liquid storage area 12 are respectively provided with a water inlet 13 and a water outlet 14 communicated with the dehydration pipeline 10. The bottom of the buffer tank 1 is conical, and the bottom of the buffer tank 1 is provided with a sludge drain. Outlet 15, the sludge discharge port 15 is provided with a sludge recovery device 3, and the bottom of the buffer tank 1 is also provided with a sludge scraper device 4 capable of scr...

Embodiment 2

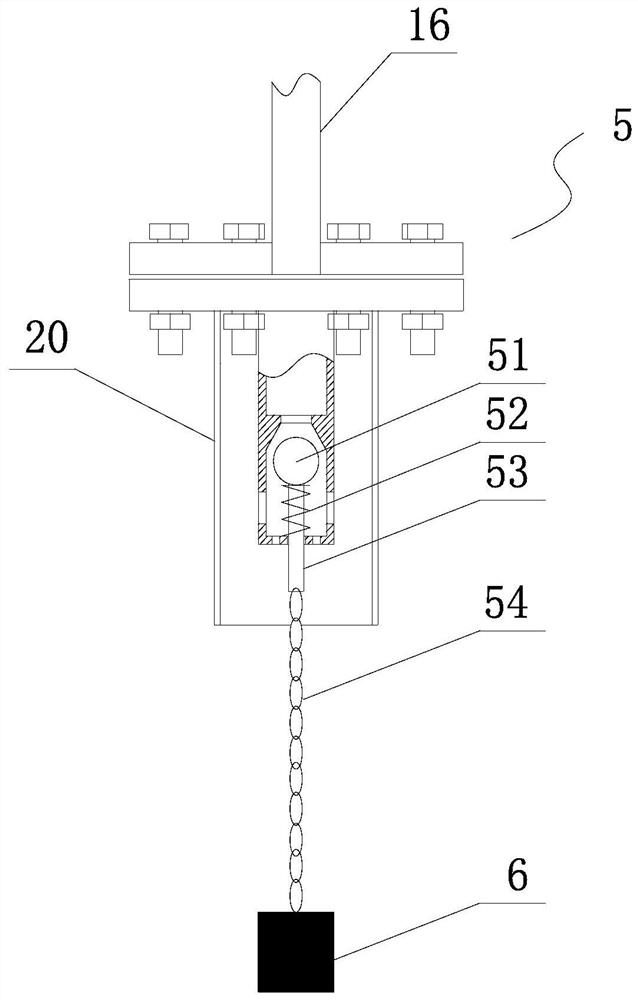

[0034] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 4 As shown, the valve body of the switching valve assembly 5' is provided with a valve core 51' for blocking the breathing port 16, and the bottom of the valve core 51' is connected to a valve stem 53 equipped with a lever type touch switch 52' ', the end of the valve stem 53' is connected with a connecting chain 54', and a weight 6 is suspended from the end of the connecting chain 54'. The lever type touch switch 52' includes a lever hinged on the connecting block 20, one end of the lever is provided with a counterweight 521', the other end is provided with a sliding groove 522', and the end of the valve rod 53' It forms a sliding connection with the bottom of the sliding groove 522'. The sealing partition 2 will drive the weight 6 to lift the valve core 51' when the liquid level in the lower liquid storage area rises, and the valve core 51' will close the breathing port 16 after risi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com