Electromagnetic Contactor

An electromagnetic contactor and connecting part technology, applied in electromagnetic relays, relays, electromagnetic relay detailed information and other directions, can solve the problems of insufficient wiring space, narrow interval, and difficulty in routing external wiring, and achieve easy wiring operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

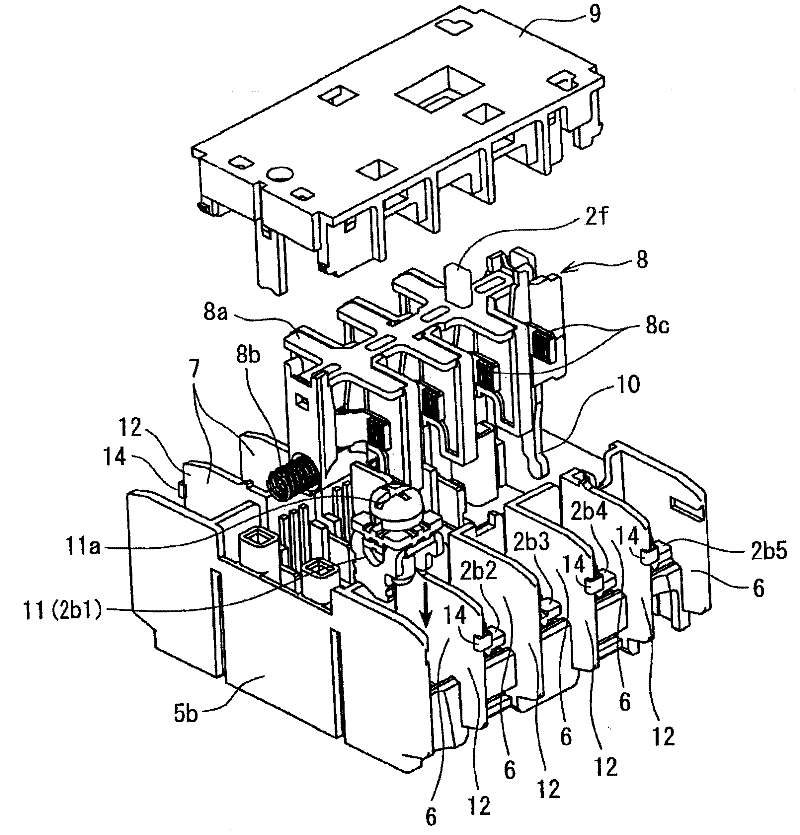

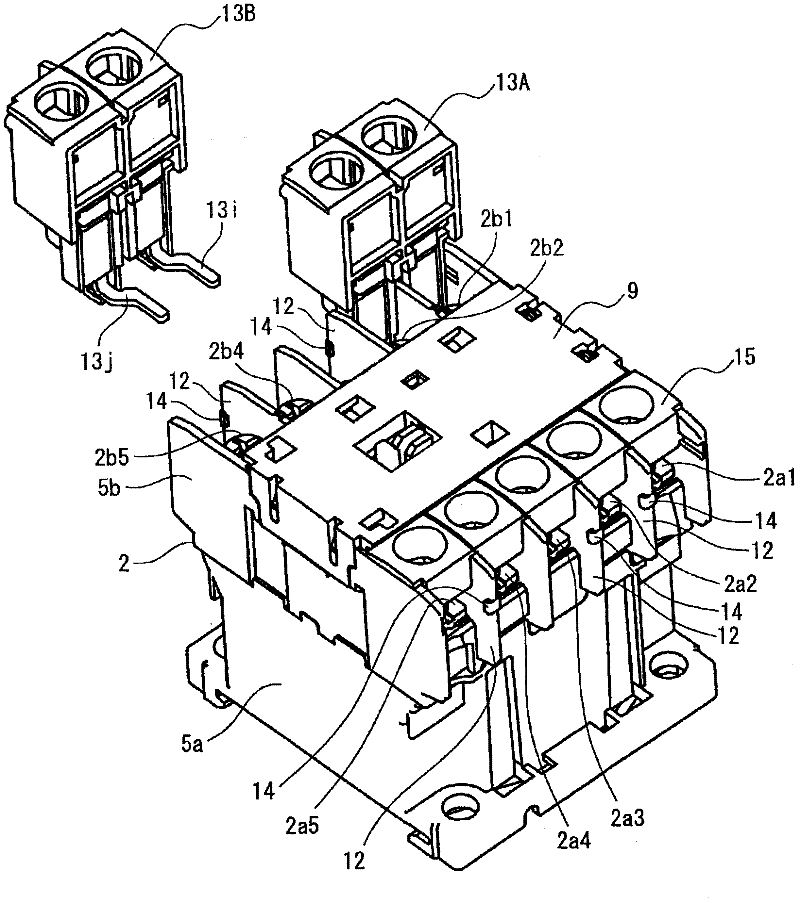

[0071] Hereinafter, best modes for carrying out the present invention (hereinafter referred to as embodiments) will be described in detail with reference to the drawings. In the following embodiments, various limitations are given to constituent elements, types, combinations, shapes, relative arrangements, etc., but these are merely examples, and the present invention is not limited thereto. for with Figure 8 and Figure 9 Portions having the same structure are denoted by the same reference numerals, and explanations thereof are omitted.

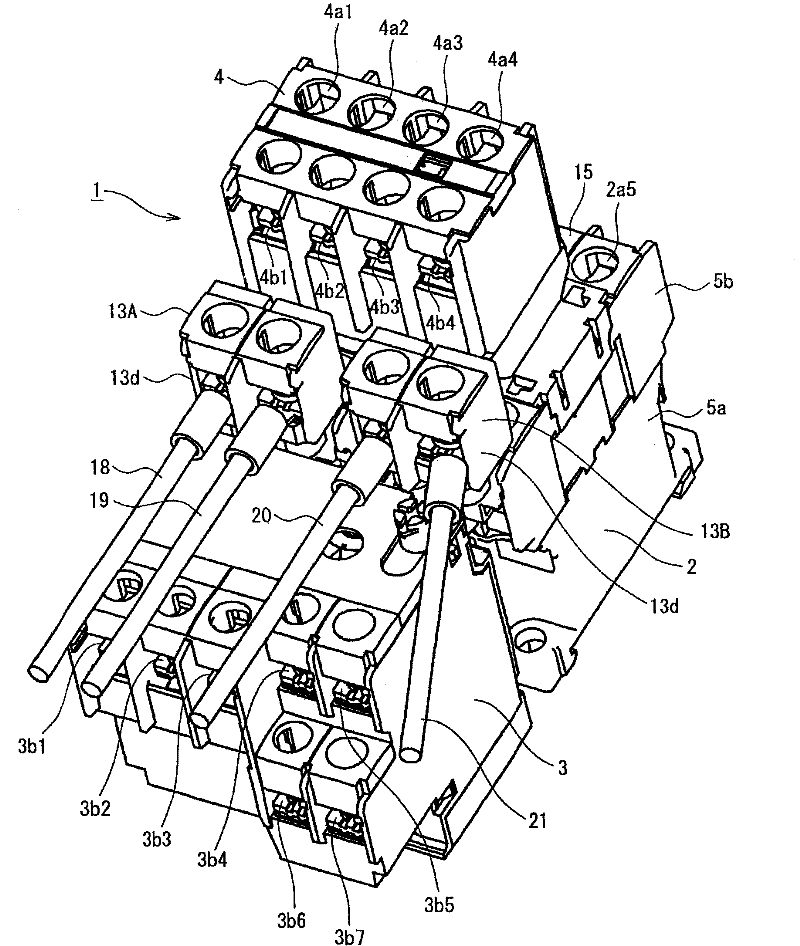

[0072] figure 1 It shows the electromagnetic switch 1 related to the present invention, the first relay terminal block 13A is connected to the load side main circuit terminals 2b1 and 2b2 on the other side of the electromagnetic contactor 2, and the second relay terminal block 13B is connected to the load side auxiliary terminal 2b4 is connected to the load side coil terminal 2b5.

[0073] The housing of the electromagnetic contactor 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com