Plate measuring element

A technology for measuring components and plates, applied in general parts of printing machinery, printing, printing machines, etc., can solve the problem of not being able to accurately determine the center point of point clusters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

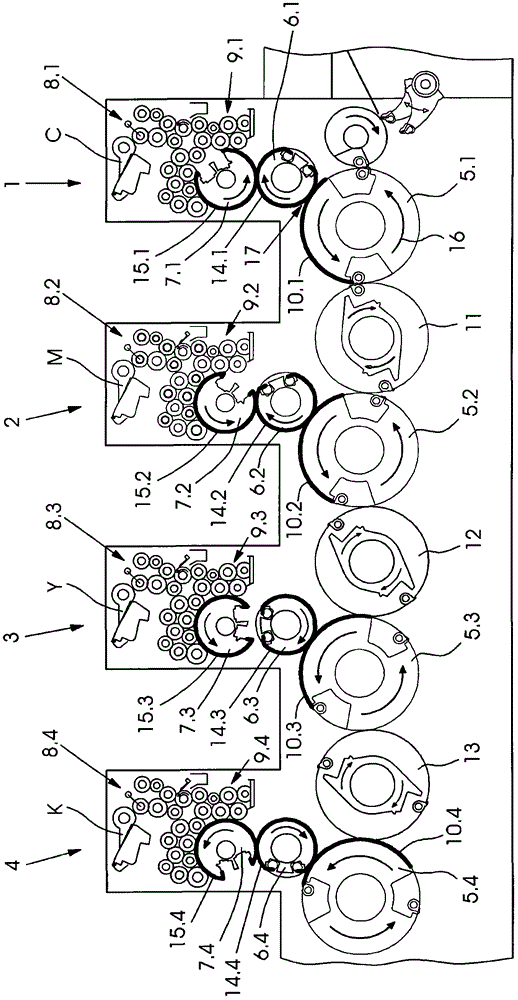

[0013] figure 1 Four printing units of an offset printing press are shown. Each printing unit 1 to 4 comprises an impression cylinder 5.1 to 5.4, a transfer cylinder 6.1 to 6.4 and a plate cylinder 7.1 to 7.4. An ink unit 8.1 to 8.4 and a dampening unit 9.1 to 9.4 are assigned to each plate cylinder 7.1 to 7.4. For conveying the sheets 10.1 to 10.4, transfer rollers 11 to 13 are located between the impression cylinders 5.1 to 5.4. The blankets 14.1 to 14.4 are stretched over the transfer cylinders 6.1 to 6.4. The printing plates 15.1 to 15.4 are stretched on the printing plate cylinders 7.1 to 7.4. During printing, the cylinder and roller rotate in the direction of arrow 16 .

[0014] During printing, the printing plates 15.1 to 15.4 are inked image-wise by means of corresponding ink units 8.1 to 8.4 and dampening units 9.1 to 9.4. The printing inks C, M, Y, K of the partial images reach the blankets 14.1 to 14.4 from the printing plates 15.1 to 15.4. If the sheets 10.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com