Pumping machinery, pumping system and dispensing valves thereof, and method of operation of the pumping system

A technology of a pumping system and an operation method is applied to a pumping machine and an operation method of the pumping system. It can solve the problems of complex operation method, large switching resistance of distribution valve, complicated structure of distribution valve, etc., and achieve the effect of continuous pumping and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not be regarded as limiting the technical content disclosed in the present invention.

[0053] In this section, the mouth that enters the corresponding passage is the entrance of the passage, and the mouth that flows out of the corresponding passage is the exit of the passage.

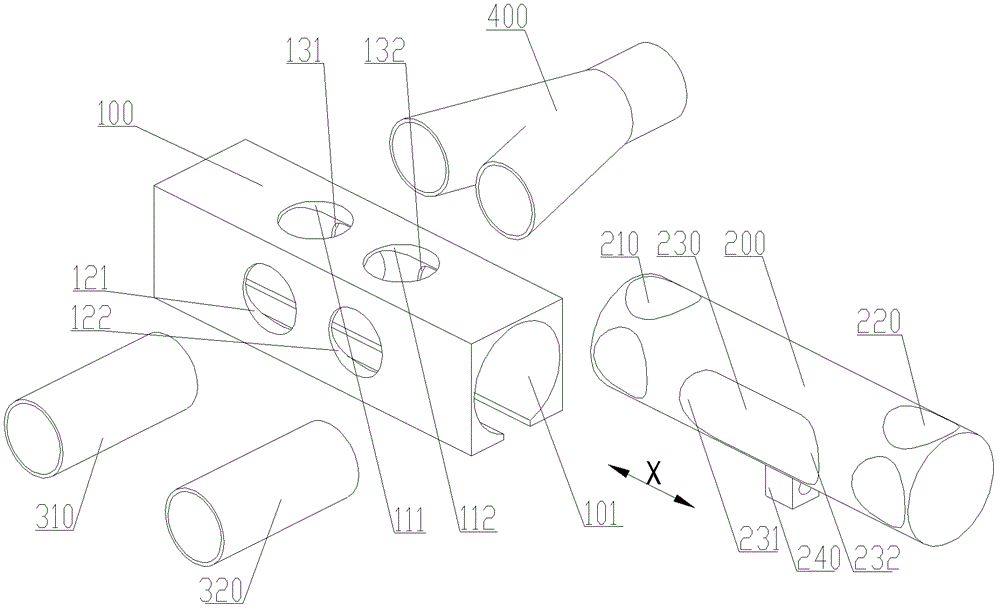

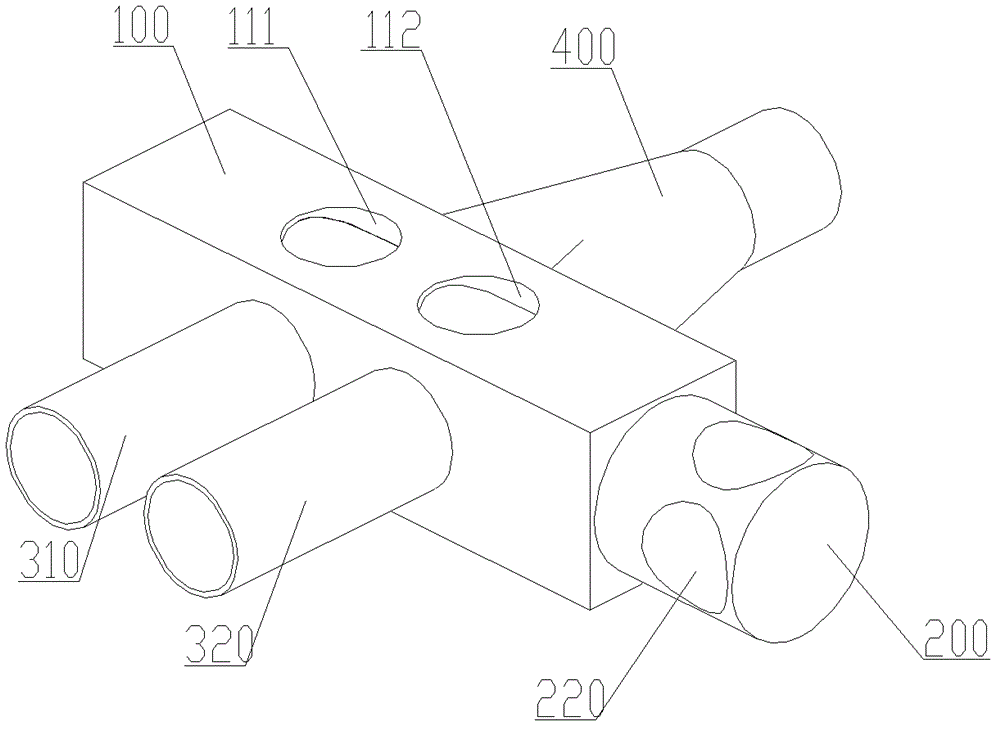

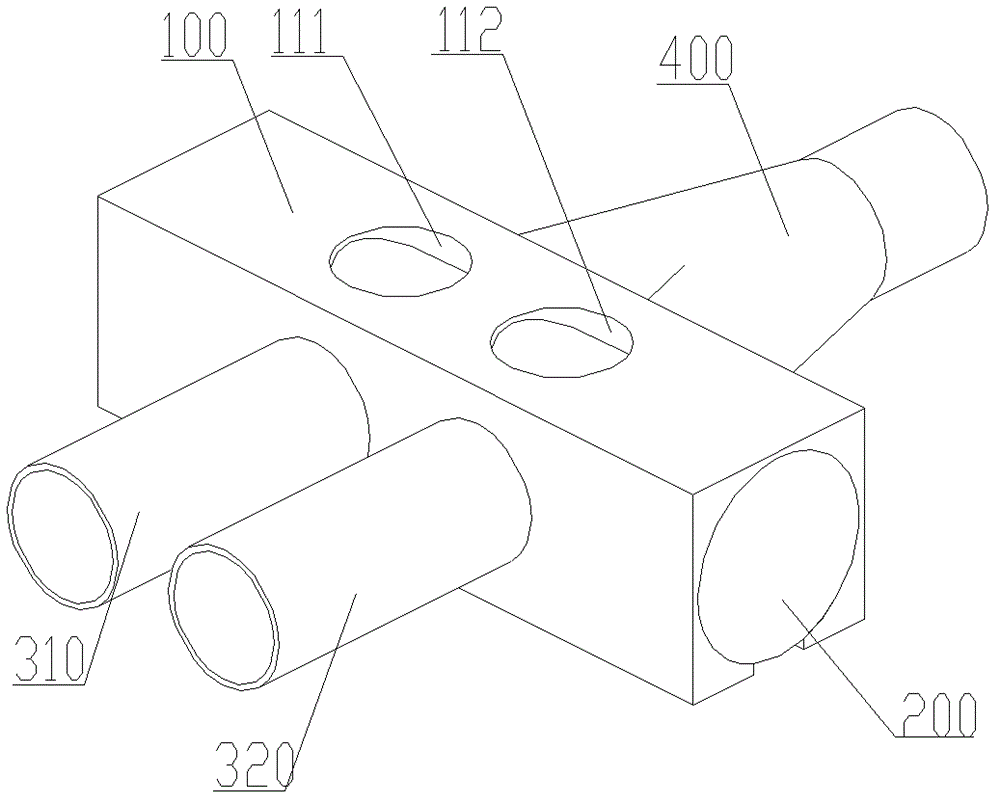

[0054] Please refer to figure 1 and Figure 2, figure 1 It is an exploded diagram of the dispensing valve of the pumping system provided by the present invention; diagram 2-1 It is an assembly diagram of the dispensing valve of the pumping system provided by the present invention, which also shows the structure of the dispensing valve in the first state; for the convenience of description, figure 1 And the Y-shaped joints of the two delivery cylinders and delivery pipes also shown in Figure 2.

[0055] The dispensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com