Clamp element

A clip element and clip technology are applied in the field of clip elements to achieve the effect of improving torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

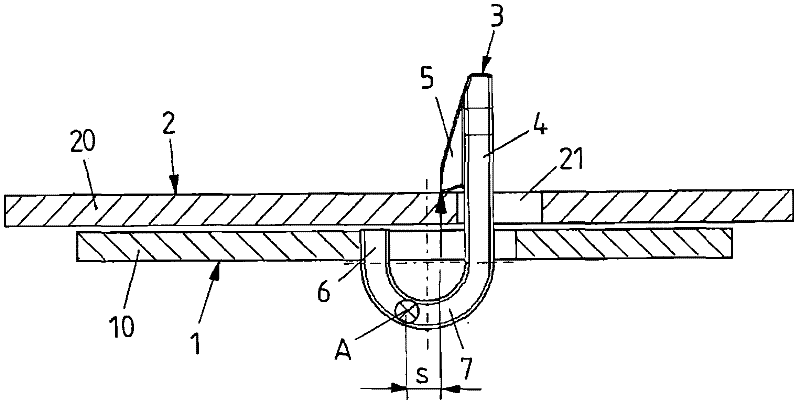

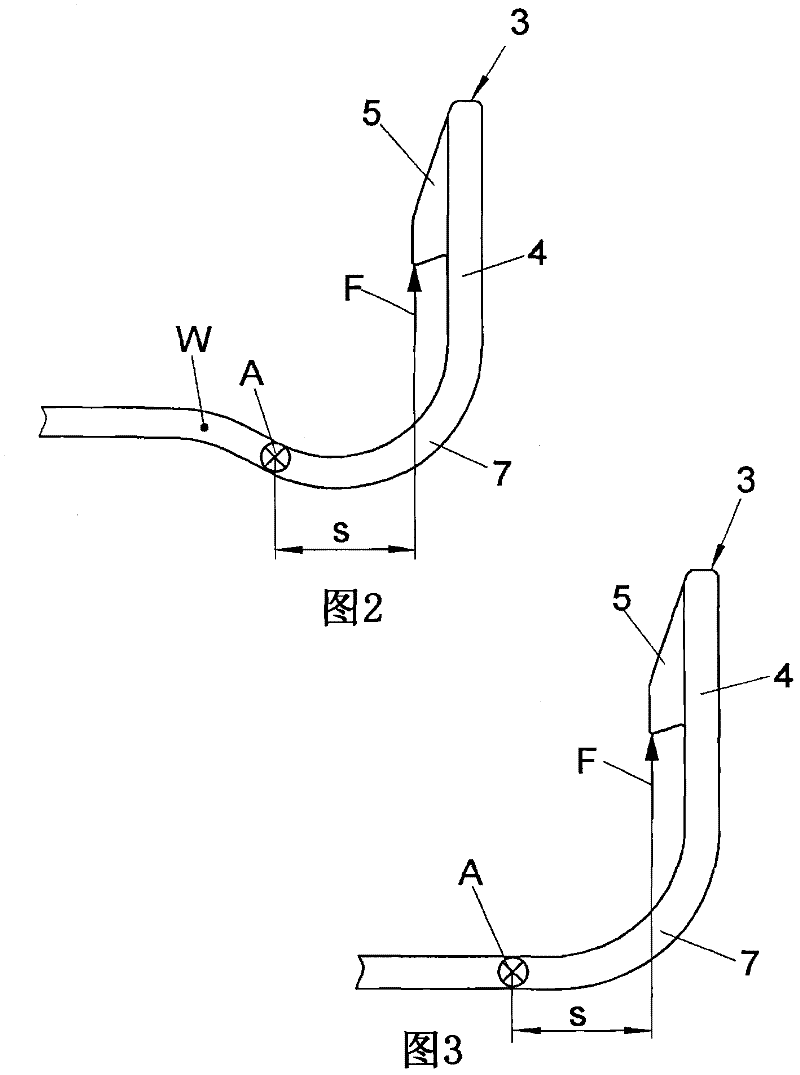

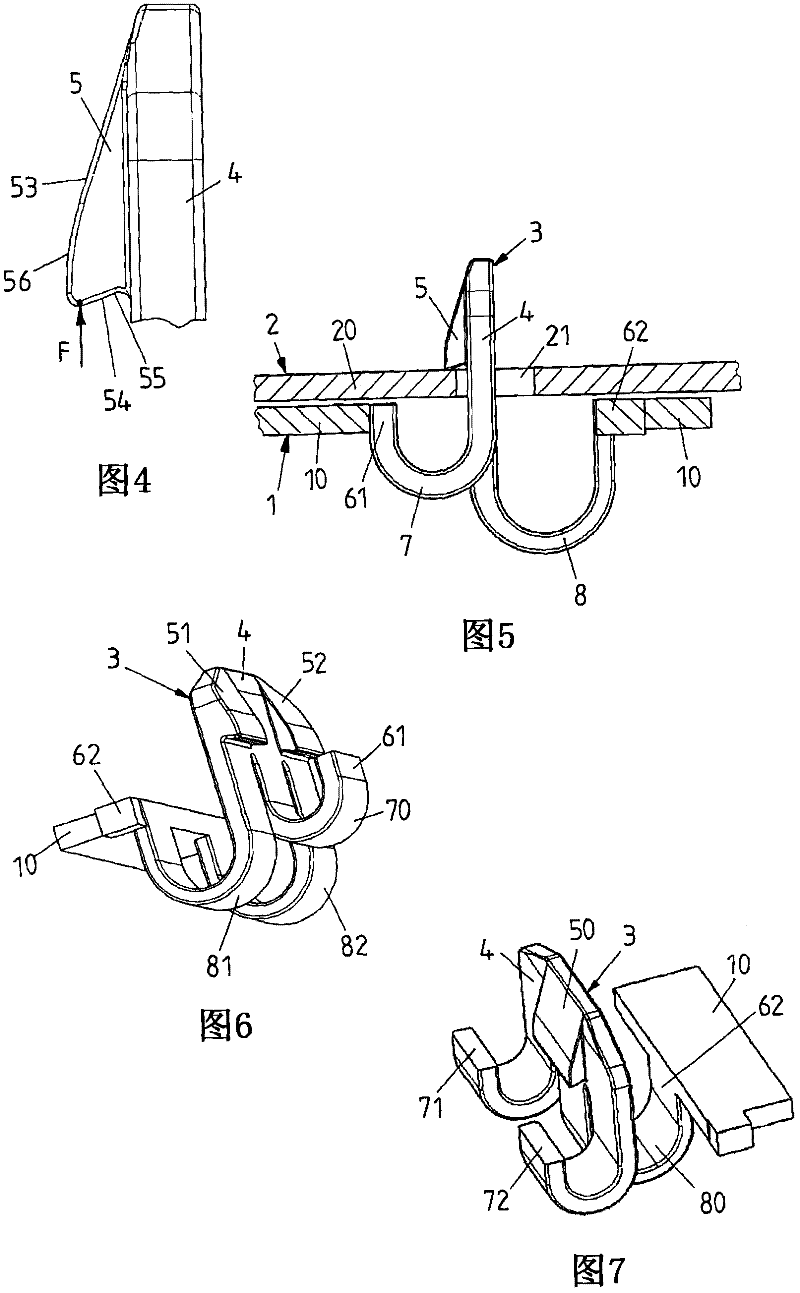

[0055] figure 1 A side view of the clip element 3 for the connection of the base body 10 of the component 1 , which is connected via the connection region 61 with the clip element 3 to the base plate 20 of the component 2 , is shown. The clip element 3 comprises a base 4 to which a clip hook 5 is integrally molded at one end and whose other end is connected to the base body 10 of the component 1 via a connection area 61 . Between the two ends, the base 4 has a spring leg 7 bent in a U-shaped manner, which encloses an angle of 180° between the area of the base 4 where the clip hook 5 is integrally molded and the connection area 61 .

[0056] Figure 4 The clip hook 5 , shown enlarged in FIG. The surface of the base 4 extends vertically, or as Figure 4 As shown, an undercut 55 is formed extending from the base 4 at an acute angle.

[0057] In the base plate 20 of the assembly 2 , a clip socket 21 is provided in the form of an opening into which the clip element 3 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com