Integrated enamel electroluminescent panel

A technology of electroluminescent panels and electroluminescent elements, applied in the direction of electroluminescent light sources, electric light sources, light sources, etc., can solve the problems of increased trouble, high cost, and restrictions on the wide application of enamel electroluminescent panels, so as to avoid falling off , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

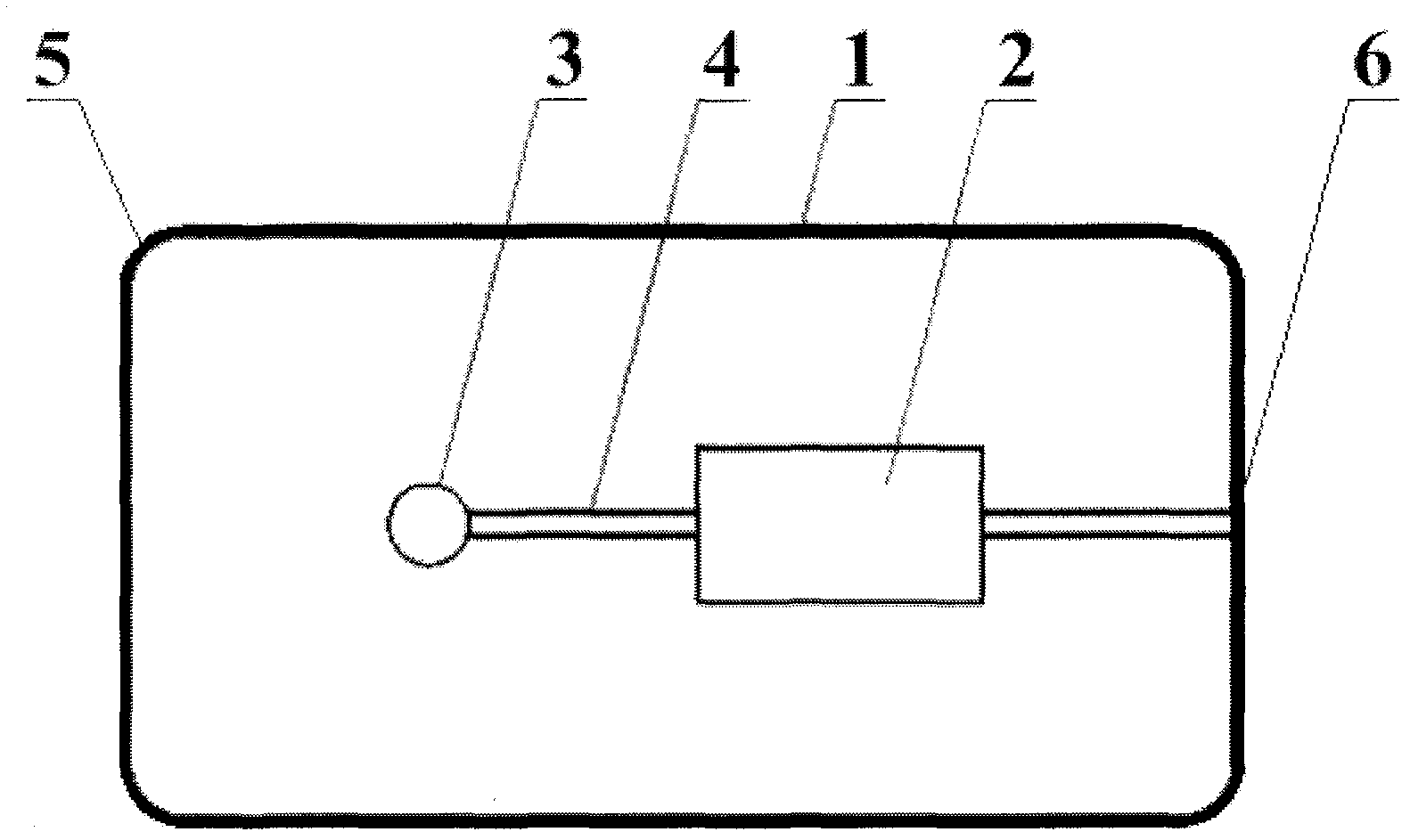

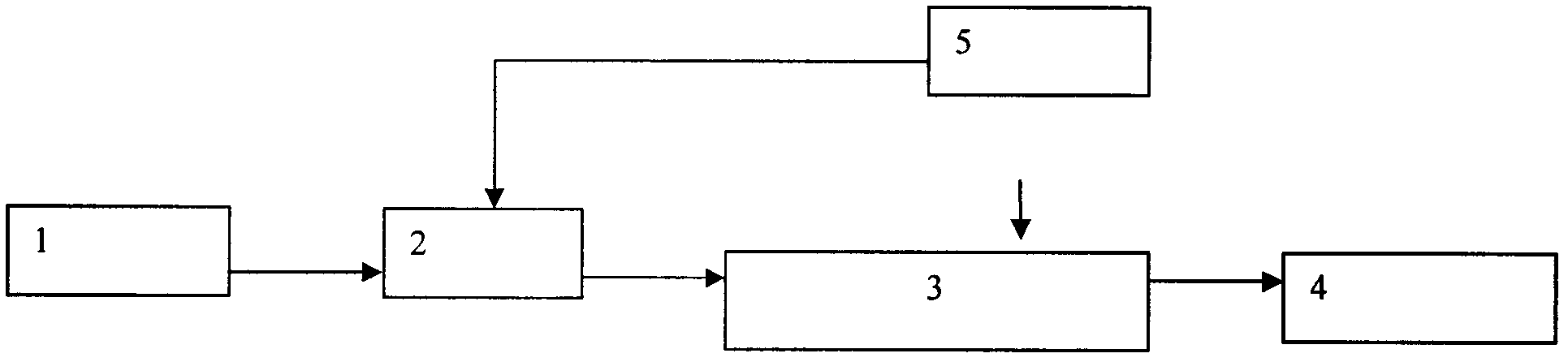

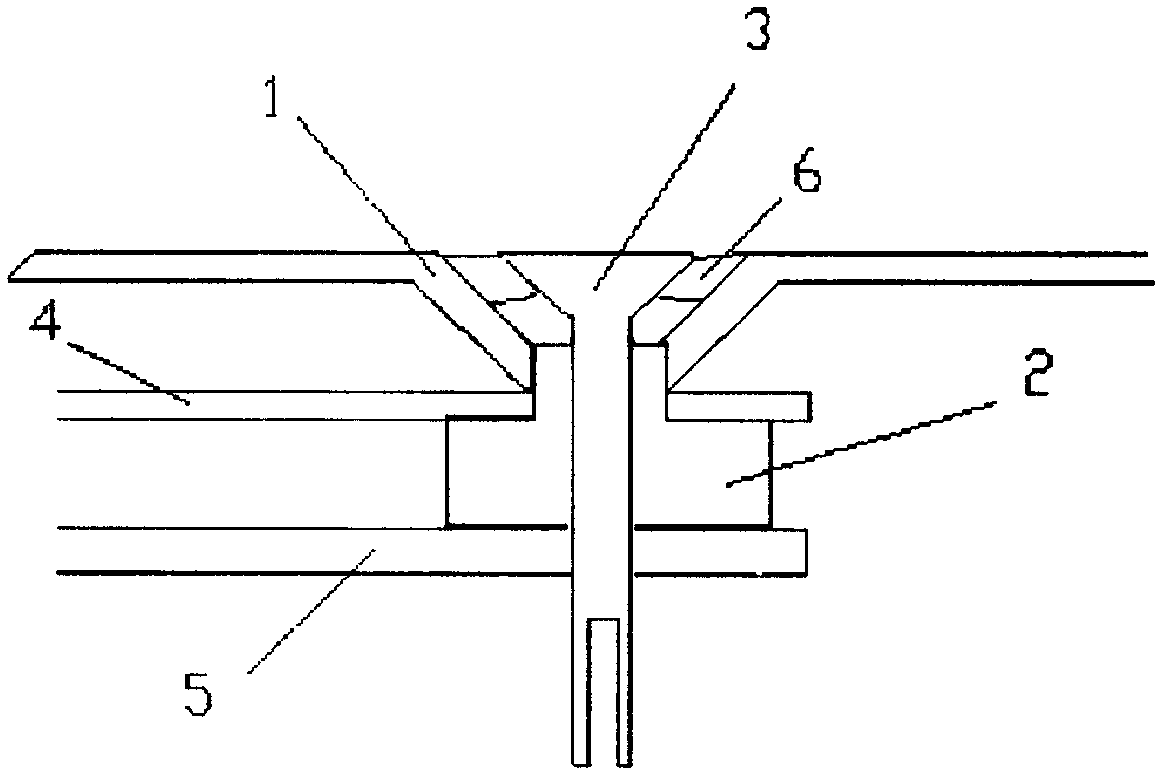

[0010] figure 1 It is the structural diagram of the integrated enamel electroluminescent board. The basic shape of the enamel electroluminescent element 1 is a rectangle. According to the application requirements of different professional fields, the enamel electroluminescent element 1 can also be circular, oval, triangular or other irregular shapes. The light-emitting element 1 is equipped with a micro electrode 2, a micro driving power supply 3 and an external power supply jack 4, and the electrode 2, the micro driving power supply 3 and the external power supply jack 6 are connected by a connection line 4. The size of the micro-drive power supply 3 is 60-80 mm long, 20-30 mm wide, and 3-8 mm thick, and is inlaid on the back of the enamel electroluminescent element 1. One end is connected to the micro-electrode 2, and the other end is used as a comme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap