Method for preparing polyamide foam and foam capable of being produced by said method

A technology of polyamide and foam, which is applied in the field of preparing polyamide foam, and can solve the problems of irregular cell size and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

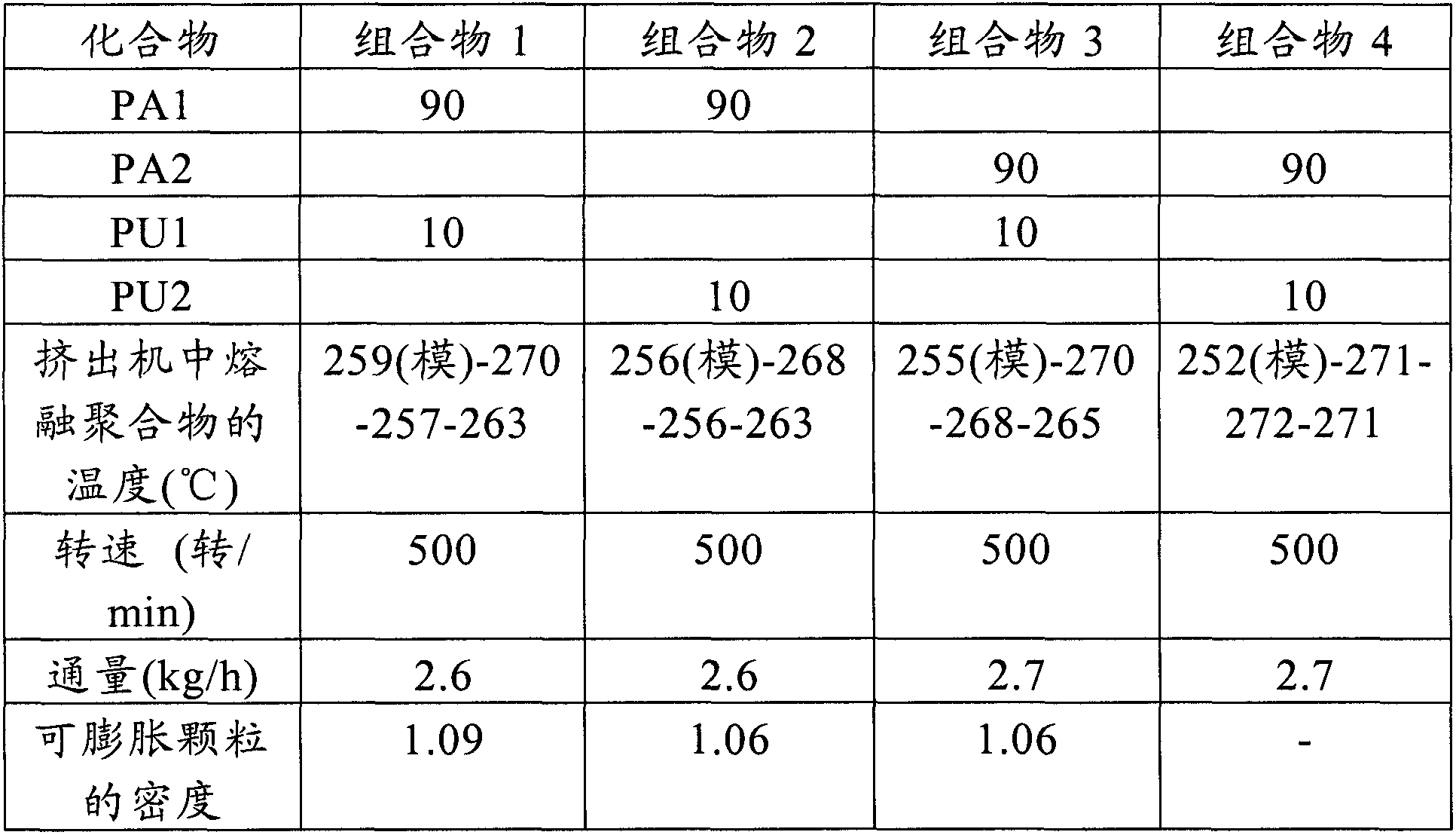

[0083] Example 1 : Preparation of expandable particles

[0084] The compounds used are as follows:

[0085] - PA1: polyamide 6,6 with a VI of 138 ml / g and containing 1500 ppm water. End group content: AEG=42meq / kg, CEG=79meq / kg.

[0086] - PA2: polyamide 6,6 with a VI of 163 ml / g and containing 900 ppm water. End group content: AEG=35meq / kg, CEG=67meq / kg.

[0087] - PU1: aliphatic thermoplastic polyurethane based on ε-caprolactone, sold under the name Krystalgran PN03-214 by Huntsman.

[0088] - PU2: aliphatic thermoplastic polyurethane based on polyester, sold under the name Krystalgran PN3429-218 by Huntsman.

[0089] The composition was prepared by melt mixing using a co-rotating twin-screw extruder of the Thermo Prism type (model TSE16TC, length / diameter ratio 25). The prepared compositions and extrusion conditions are detailed in Table 1. Compound ratios are expressed in weight percent of the composition.

[0090] The extruded composition was cooled in water to a...

Embodiment 2

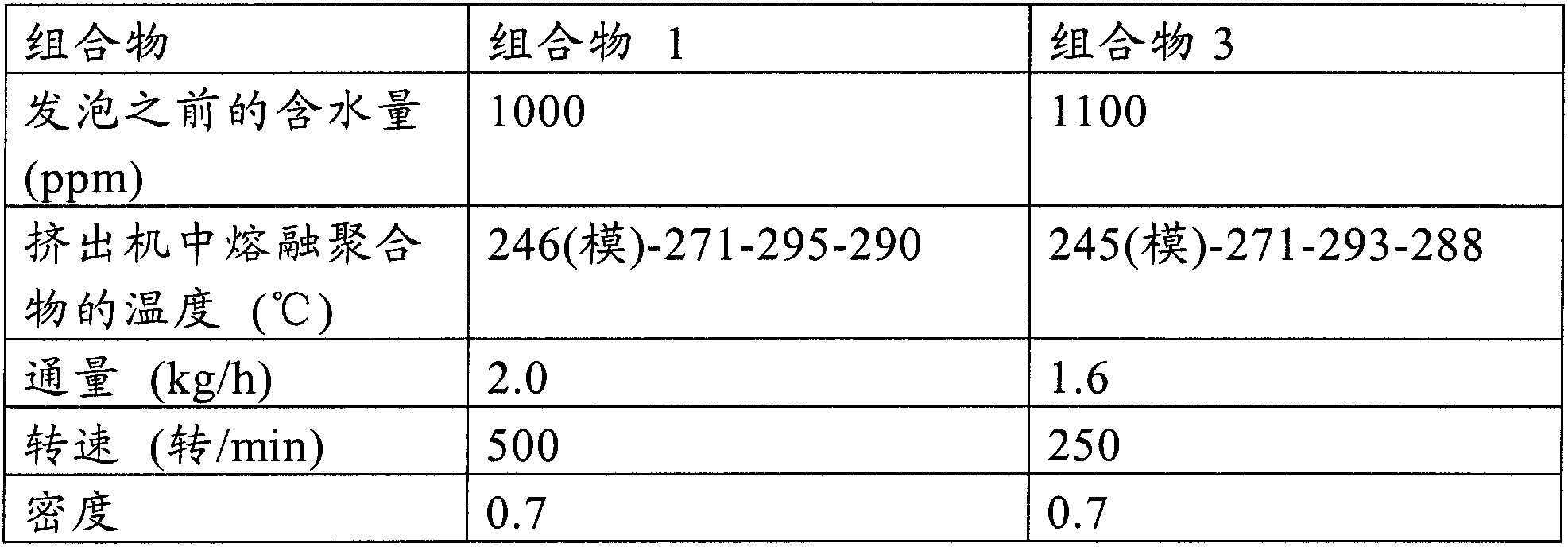

[0094] Example 2 : The use of extrusion equipment to prepare expanded materials

[0095] The expansion of the expandable particles of Example 1 was carried out in the melt phase using a co-rotating twin-screw extruder of the Thermo Prism type, type TSE16TC, with a length / diameter ratio of 25.

[0096] Extrusion conditions and resulting densities are summarized in Table 2.

[0097] Table 2

[0098]

[0099] In both cases, the pore distribution is closed.

Embodiment 3

[0100] Example 3 : Utilize injection molding equipment to prepare expanded products

[0101] The expansion of the expandable particles of Example 1 was carried out in the melt phase using a BOY 12M 129-18 injection molding machine from Bewe Plast with a plate mold of dimensions (mm) 80×10×4. The injection molding conditions and resulting densities are summarized in Table 3.

[0102] table 3

[0103]

[0104] In both cases, the pore distribution is closed. The core / skin structure was observed to have a cell size gradient from about 50 μm below the skin to about 1 mm in the core (see attached figure 1 , which corresponds to composition 1), a typical structural foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com