Tetherless tube inspection system

A non-destructive inspection and drive system technology, applied to pipe components, pipes/pipe joints/pipe fittings, and detecting the presence of fluid at leakage points, etc., can solve problems such as dirty flexible shafts, large inspection equipment, and difficult inspection operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

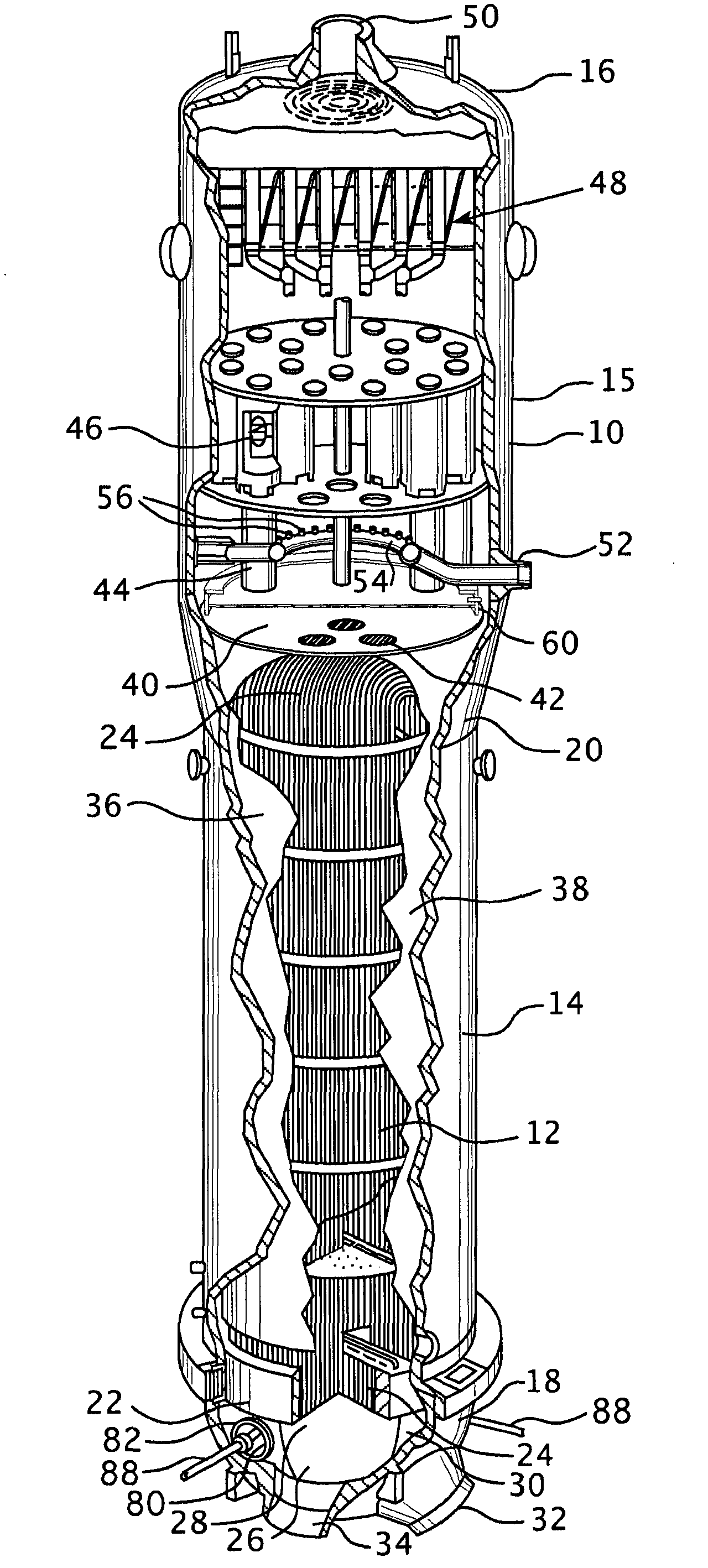

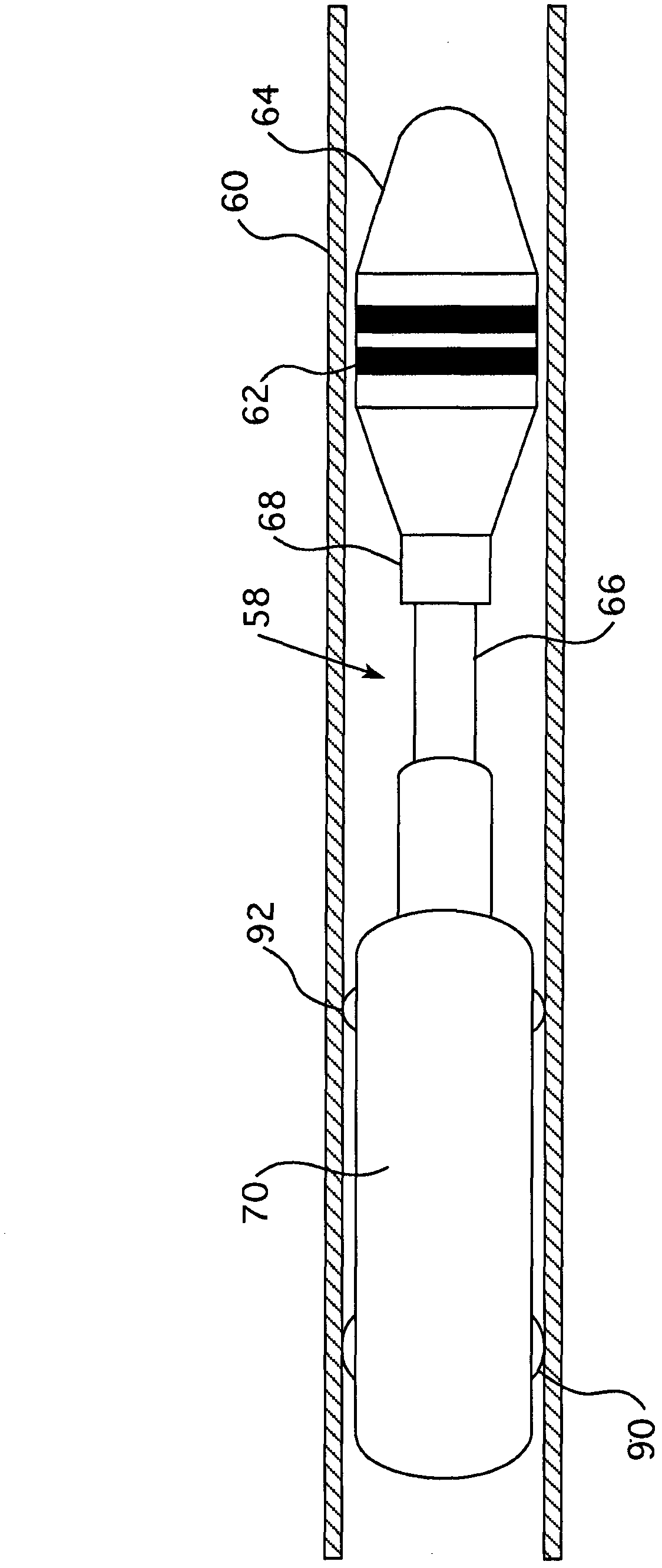

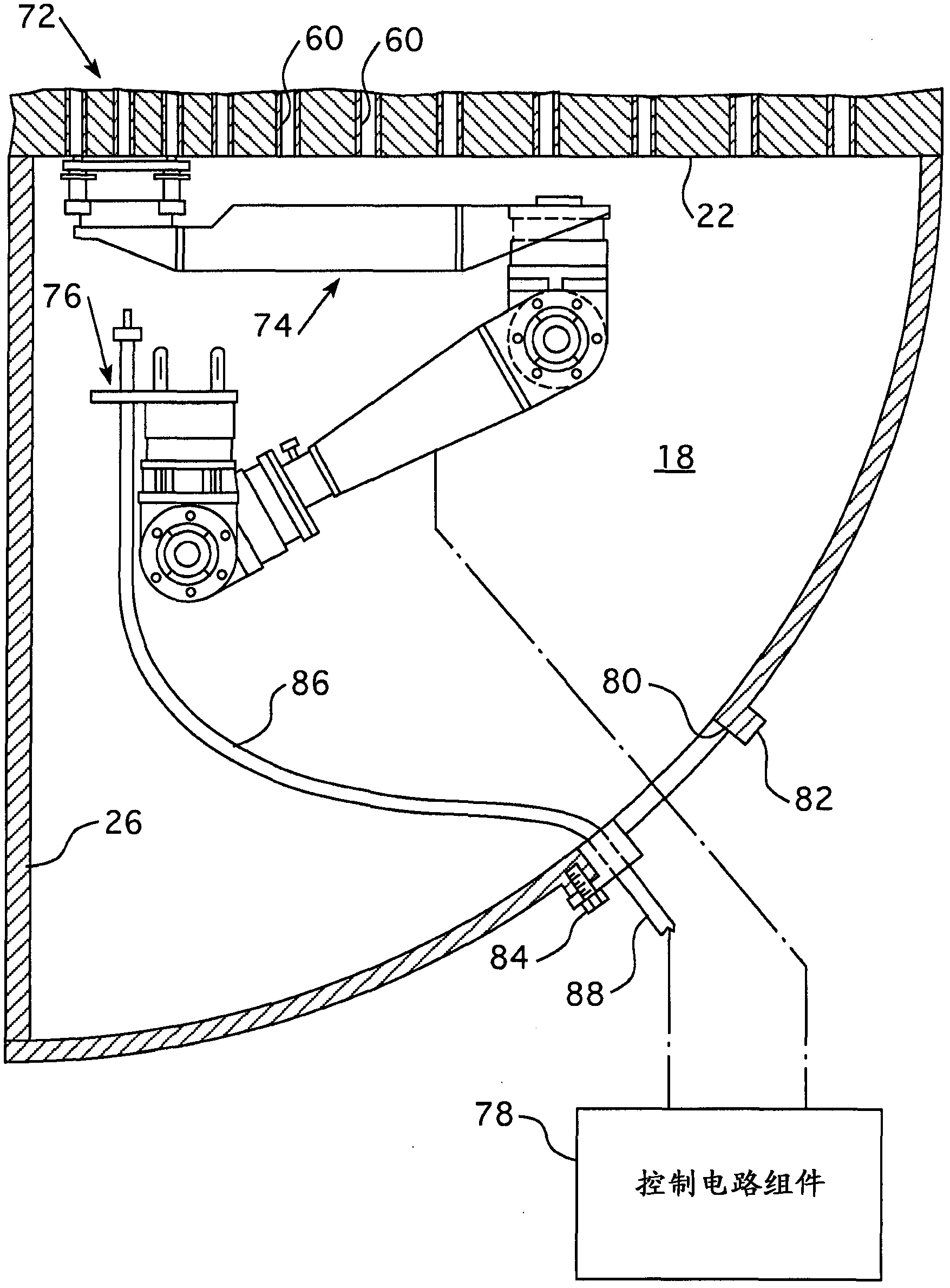

[0023] With reference to the accompanying drawings, figure 1 Shown is a steam generator 10 which utilizes a plurality of U-shaped tubes forming a tube bundle 12 to provide the heating surface required for heat transfer from a primary fluid traveling within the tubes for vaporizing or vaporizing the surrounding tube exterior. secondary fluid. The steam generator 10 comprises a vessel having a vertically oriented tubular casing with a reduced diameter lower portion 14, a conical central portion 20 and an enlarged diameter upper portion 15 and a generally hemispherical shape surrounding the lower end. The channel head 18 of the upper part is covered on top with a top casing or dish-shaped head 16 surrounding the upper end. The tube sheet 22 is attached to the channel head 18 and has a number of holes provided therein to receive the ends of the U-shaped tubes. A partition plate 26 is arranged centrally within the channel head 18 to divide the channel head into two chambers 28 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com