Forming method and mold used for reverse flanging based on 90° web surface

A technology of reverse flanging and web surface, applied in the field of cold stamping, can solve the problems that will affect the strength of the parts, material waste, poor quality, etc., and achieve the effects of simple structure, reduced production costs, and improved material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

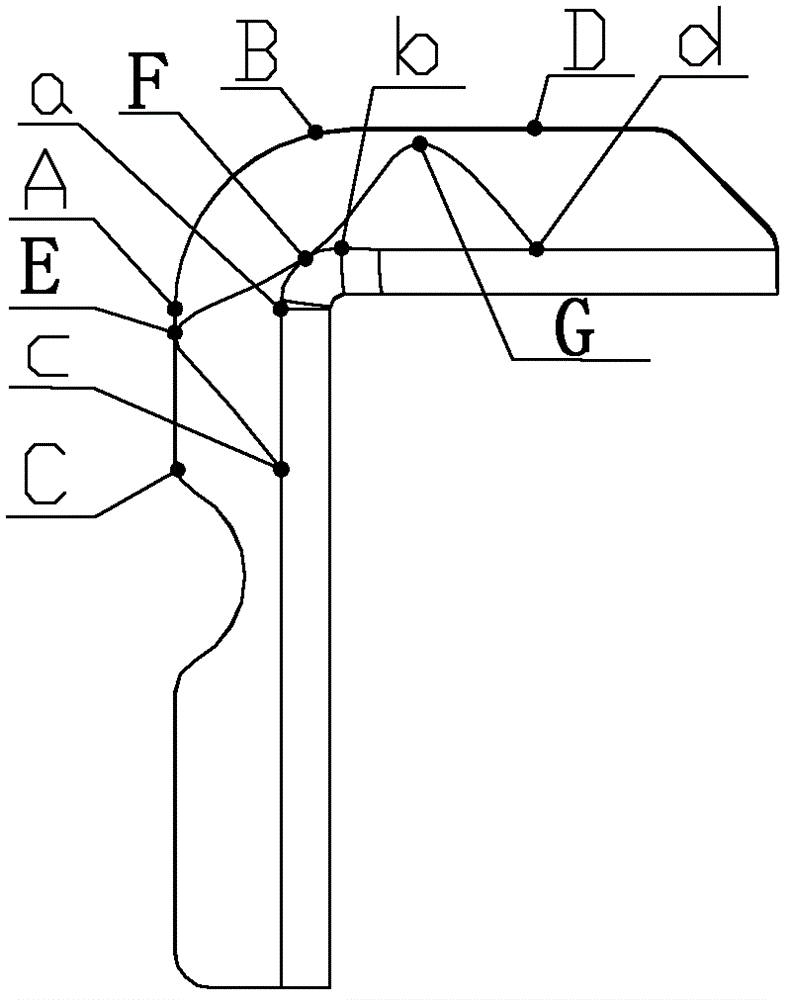

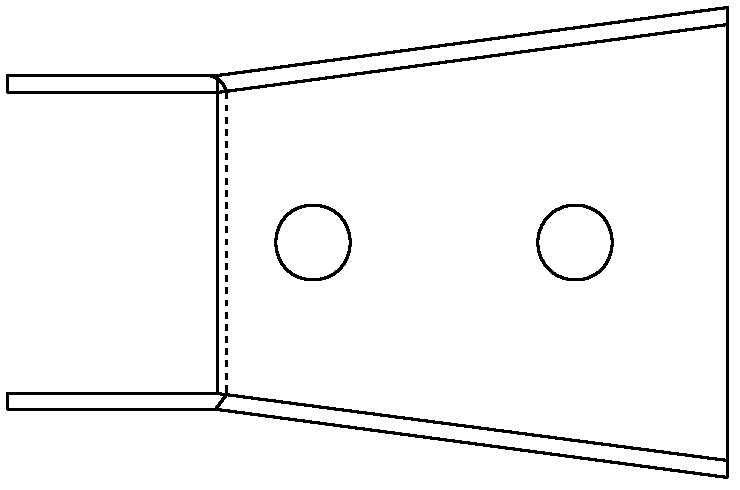

[0021] Based on the forming method of reverse flanging on the 90° web surface, firstly, the deformation area to be flanged of the unfolded part is enlarged through a wave-pressing mold, and the edge of the expanded deformation area is pressed into a wave shape for Storage material, made into prefabricated parts (such as Figure 6 ) shown. Such as figure 1 and figure 2 As shown, first the deformation region Extended to cFd, the wave edge length is cE+EF+FG+Gd, which is approximately equal to Secondly, the prefabricated part is reversely flanged into the desired shape through a flanging forming mold.

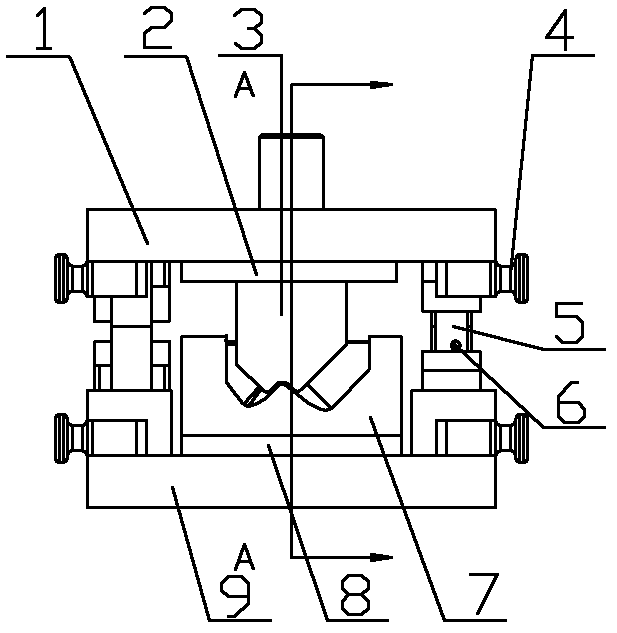

[0022] Such as image 3 and Figure 4 As shown, the wave-pressing mold includes an upper template 1 and a lower template 9, a punch fixing plate 2 is installed below the upper template, and a punch 3 is installed on the lower part of the punch fixing plate; a die holder 8 is installed above the lower template, and A concave mold 7 that matches the shape of the punch is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com