Filter type thin film pressure reducing valve

A filter type, pressure reducing valve technology, applied in safety valves, balance valves, valve devices, etc., can solve the problems of large medium flow resistance, difficult valve body processing, and difficult positioning of filter nets, so as to achieve convenient positioning and use, reduce The difficulty of production and processing, the effect of simplifying the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

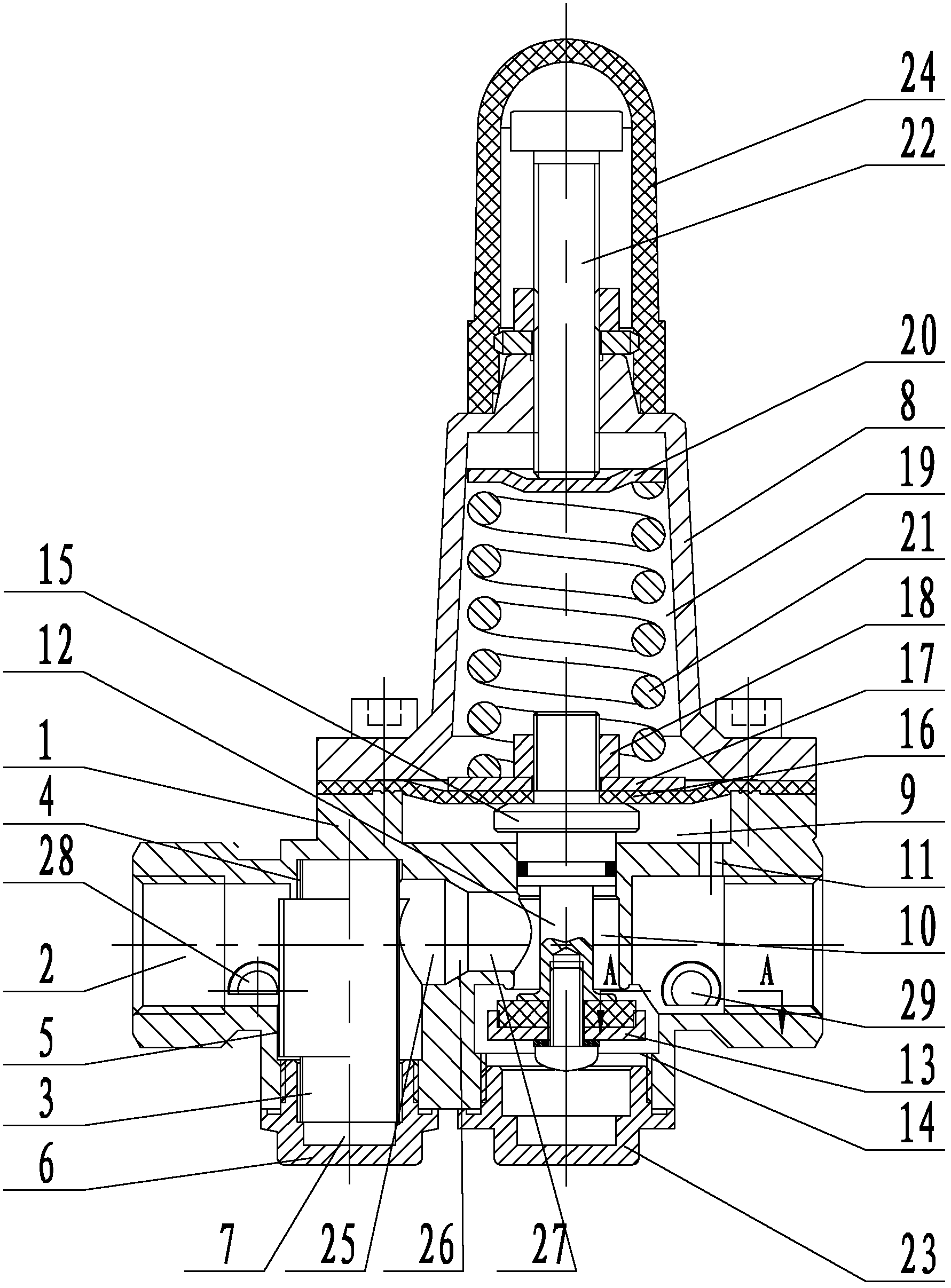

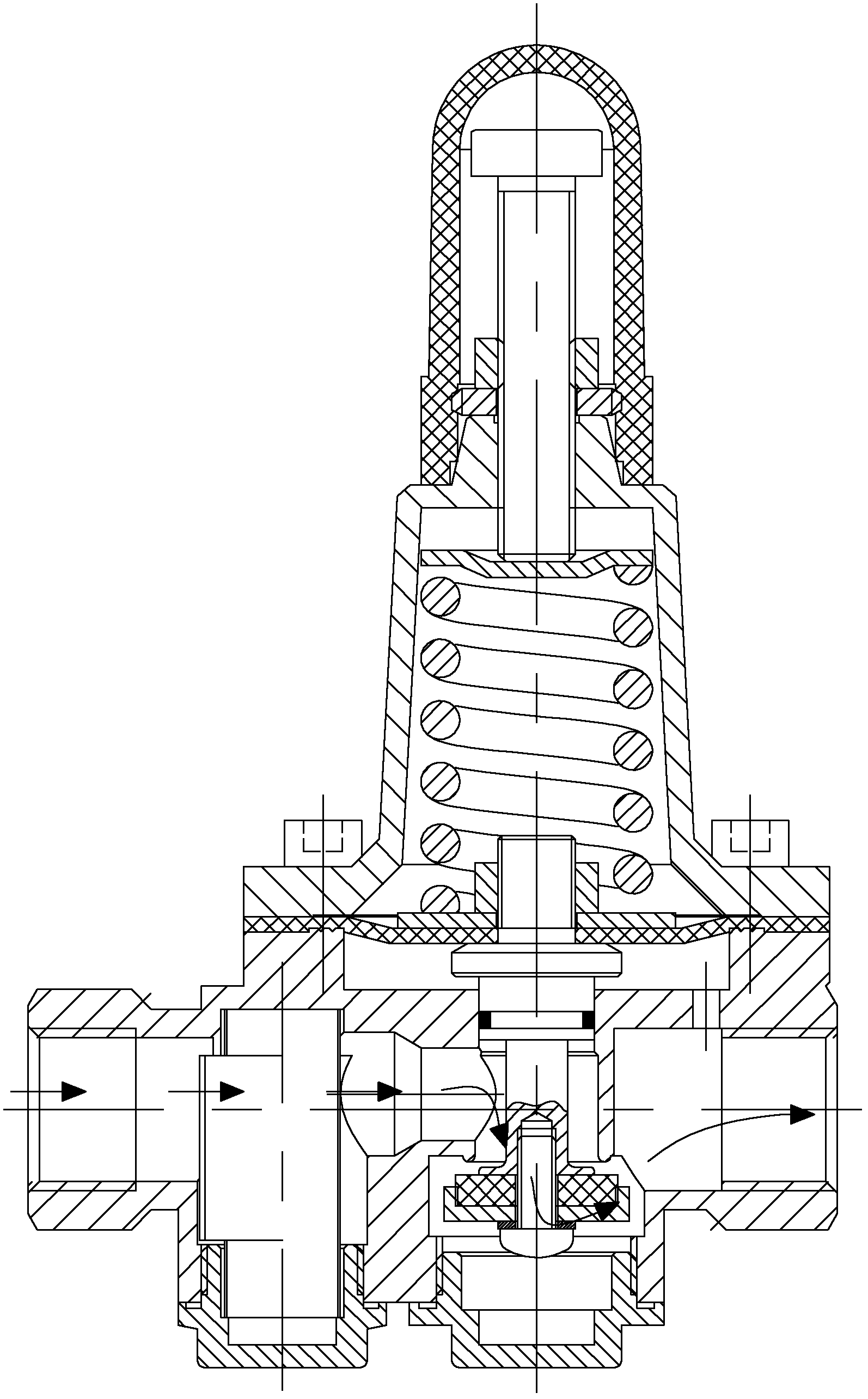

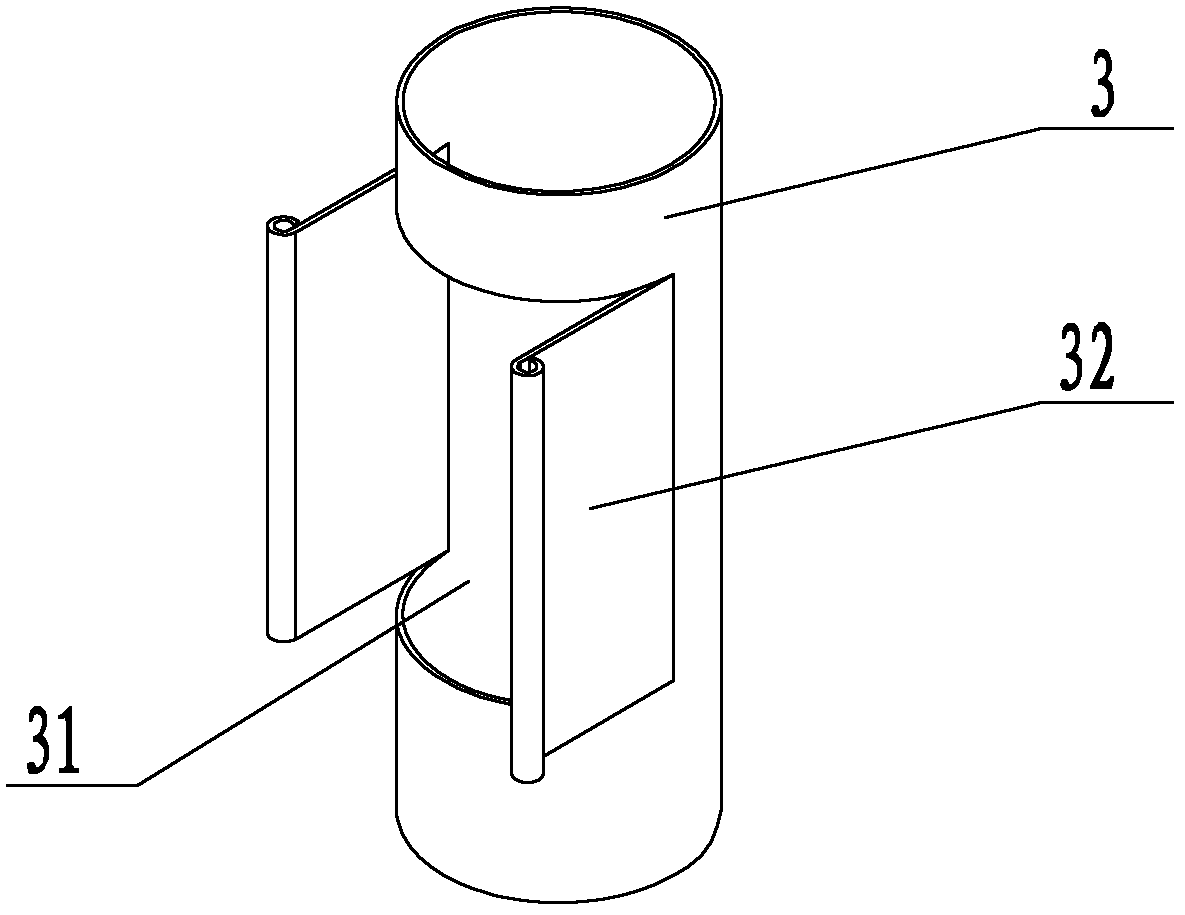

[0026] refer to figure 1 It is an embodiment of the filter type membrane pressure reducing valve of the present invention. The filter type membrane pressure reducing valve includes a valve body 1, a pressure reducing device, and a filter device. A water flow channel 2 is opened in the valve body 1. The filter device and the pressure reducing device The pressure devices are all arranged in the valve body 1, the filter device is arranged between the decompression device and the water inlet of the water flow channel, the filter device includes a filter screen 3, the filter screen 3 is cylindrical, and the filter screen 3 There is a notch 31 on the side wall of the middle part, the two vertical sides of the notch 31 are provided with fixing parts 32, and the first placement hole 4 is opened in the valve body 1, and the first placement hole 4 is connected with the water flow channel. 2, the side where the first placement hole 4 intersects with the water flow channel 2 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com