A hydraulic hammer shell assembly method based on bending and flattening technology

An assembly method and hydraulic hammer technology, which is applied in the field of hydraulic hammer processing, can solve the problems of cumbersome bending and processing of lining plates and top cover plates, and achieve the effects of convenient hoisting and positioning, guaranteed accuracy, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

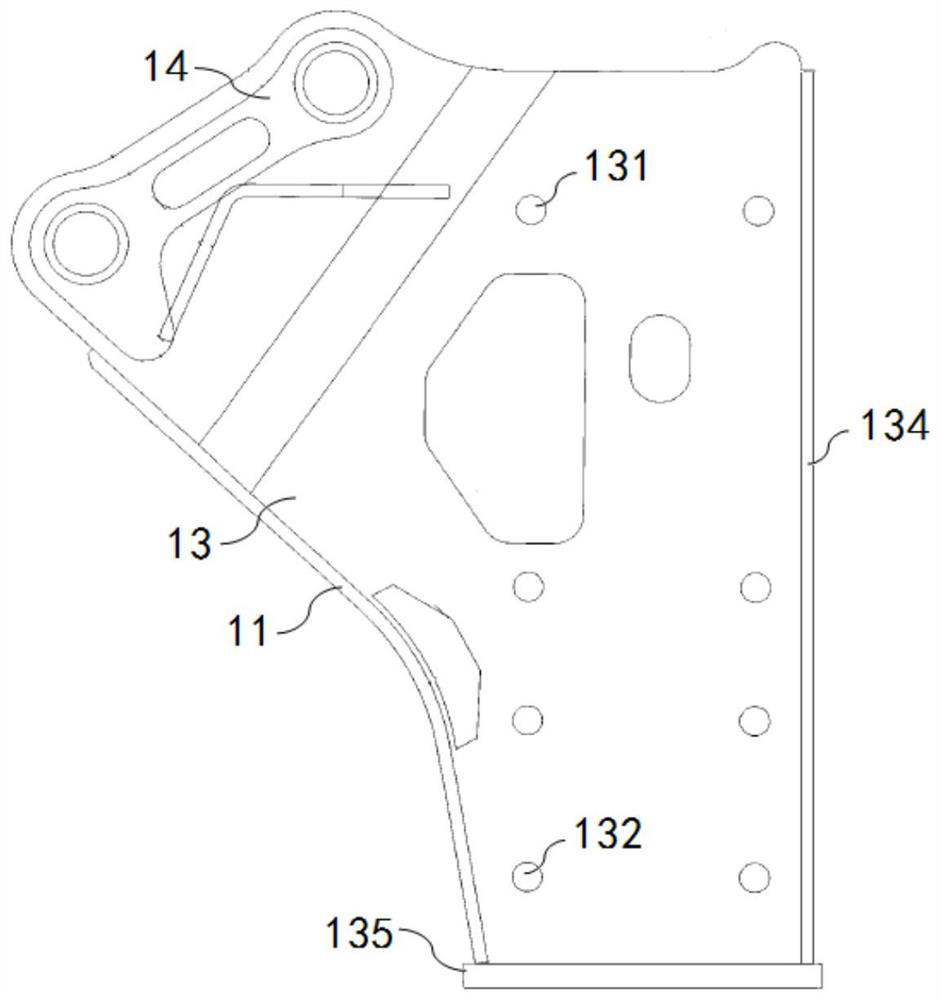

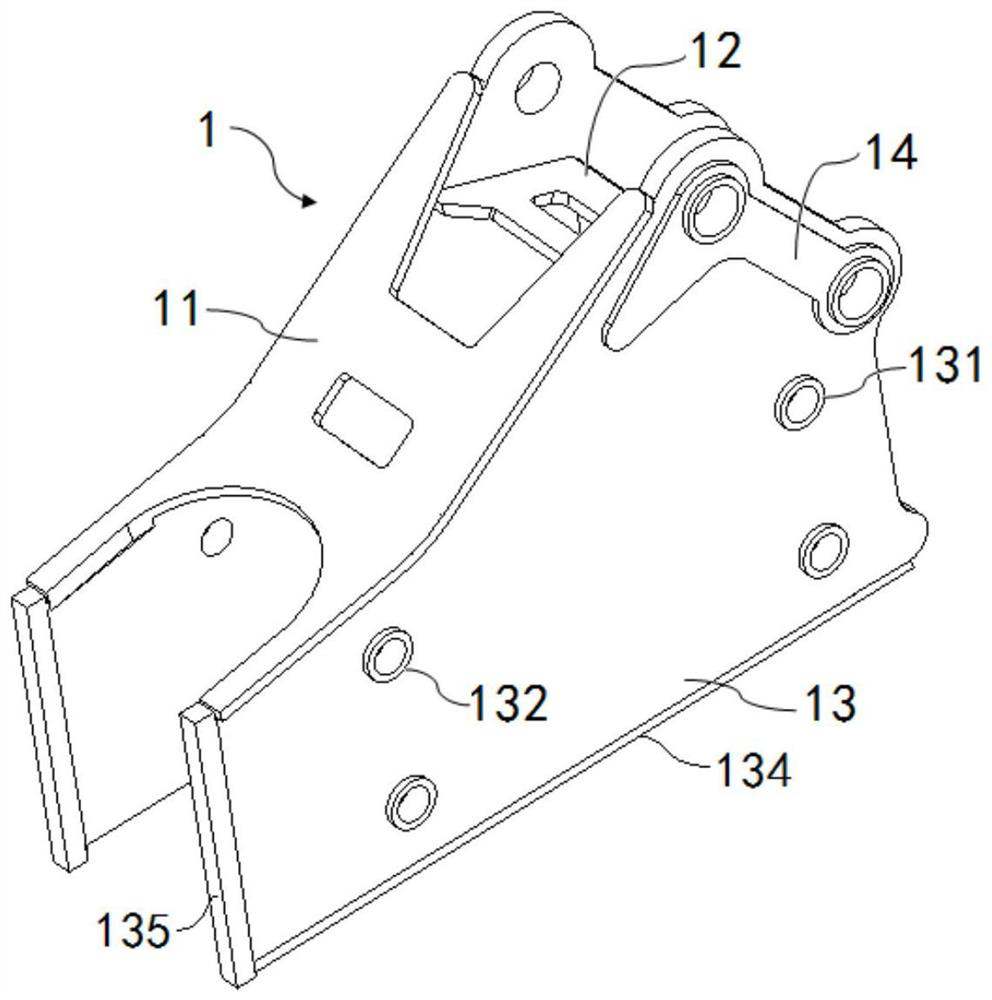

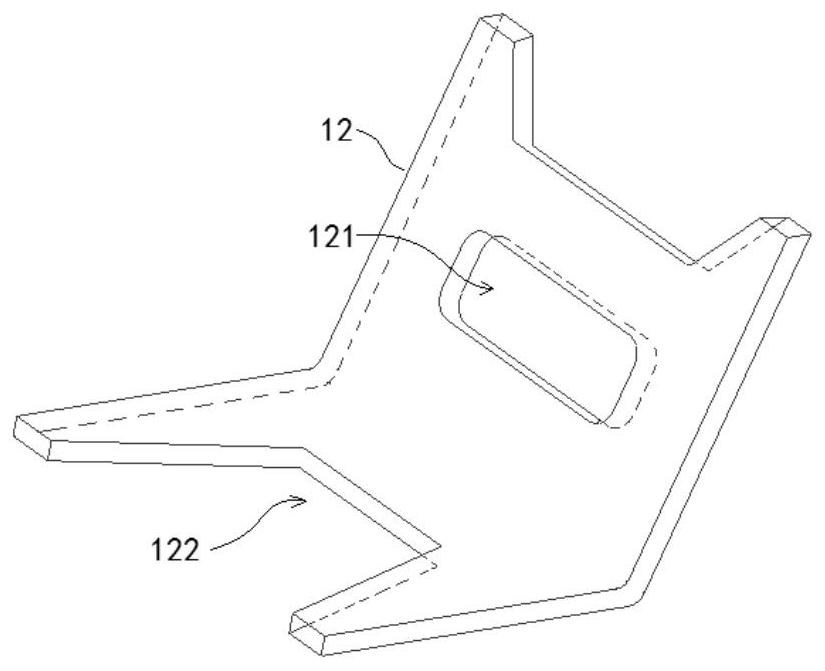

[0057] A simple processing and assembling system for a hydraulic hammer shell in this embodiment includes a bending mechanism 3 , a pressing mechanism 4 and a welding and fixing mechanism 2 . Specifically, combined with Image 6 , the lower side of the pressing bar fixing table 32 in the bending mechanism 3 is equipped with a pressing bar 35, and the pressing bar 35 is a metal plate vertically arranged, and the bottom end of the pressing bar 35 is an upper pressing die 36 with an arc surface, and the upper pressing die 36 is elongated, and its bottom surface is an arc-shaped surface, preferably an arc-shaped surface. The bending platform 34 of the bending mechanism 3 is arranged below the pressure bar fixing table 32, and the bending platform 34 is fixed with two lower dies 37, which are columnar and arranged in parallel, and the two lower dies 37 are about The longitudinal mid-section of the pressing bar 35 is symmetrically distributed, that is, on the horizontal projection ...

Embodiment 2

[0065] A simple hydraulic hammer shell processing and assembling system in this embodiment has the improvement that the distance between the centers of the lower die 37 and the upper die 36 is greater than the sum of the radii of the two, forming a certain gap with a width equal to that of the upper die 0.6 to 0.9 times the radius of 36, preferably 0.7 times, can achieve a larger bending angle, and can avoid the upper die 36 and the lower die 37 extruding the board and causing the local thickness of the board to change. In addition, the radial dimension of the lower die 37 is larger than that of the upper die 36 so that the die 36 has a certain pressing depth, otherwise it will be difficult to achieve a large angle of bending and interference will easily occur.

[0066] It is worth noting that the lower die 37 can be cylindrical, and more preferably, the top of the lower die 37 can adopt a flat top structure, that is, the top of the lower die 37 is a plane, such as Image 6 As...

Embodiment 3

[0069] A kind of simple hydraulic hammer shell processing and assembling system of this embodiment, its improvement point is that: the outside wall of box body 21 adopted is provided with collar 24, and the inner diameter of this collar 24 is equal to the size of through hole 23, and with The through holes 23 are arranged coaxially. The box body 21 can be set as a hollow structure, and the collar 24 can increase the structural strength. After being installed in the positioning shaft, it can play a main supporting role, and the through hole 23 will not be deformed after long-term use. In this embodiment, the distance between the baffle plate 25 and the positioning plate 22 is 1.4 times the thickness of the side plate 13 of the hydraulic hammer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com