On-line sampling method of reactor

A technology of reactor and sampler, applied in the field of sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

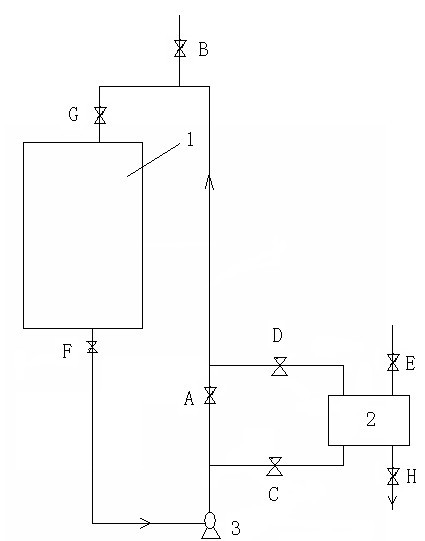

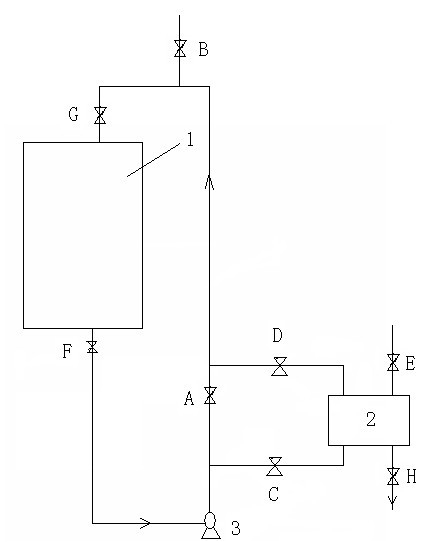

[0015] A kind of reactor online sampling method, figure 1 It is a schematic diagram of the connection between the reactor, the external circulation system and the sampler. In the figure, 1 is a reactor, 2 is a sampler, and 3 is an external circulation pump. In this method, an external circulation system is connected outside the reactor, and the sampler is connected to the external circulation system, so that the sampling result is accurate, and the materials in the reactor are not affected; the specific steps are as follows:

[0016] 1) Connect the external circulation system outside the reactor 1, connect the external circulation pump 3 to the pipeline, set the discharge valve F on the lower end pipeline of the reactor, set the feed valve G and the pipeline nitrogen inlet valve on the upper end pipeline of the reactor B; the sampler 2 is connected to the pipeline of the external circulation system through the sampling valve C and the sample return valve D, and a valve A is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com