Hanging mechanism of exhaust pipe

A suspension mechanism and exhaust pipe technology, which is used in the direction of gas intake of power plant, power plant, transportation and packaging, etc., can solve the problem of violent shaking of exhaust pipe, deformation of exhaust pipe, and easy loosening of metal parts and exhaust pipe. and other problems, to achieve good noise reduction effect and reduce vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further elaborated below in conjunction with accompanying drawing:

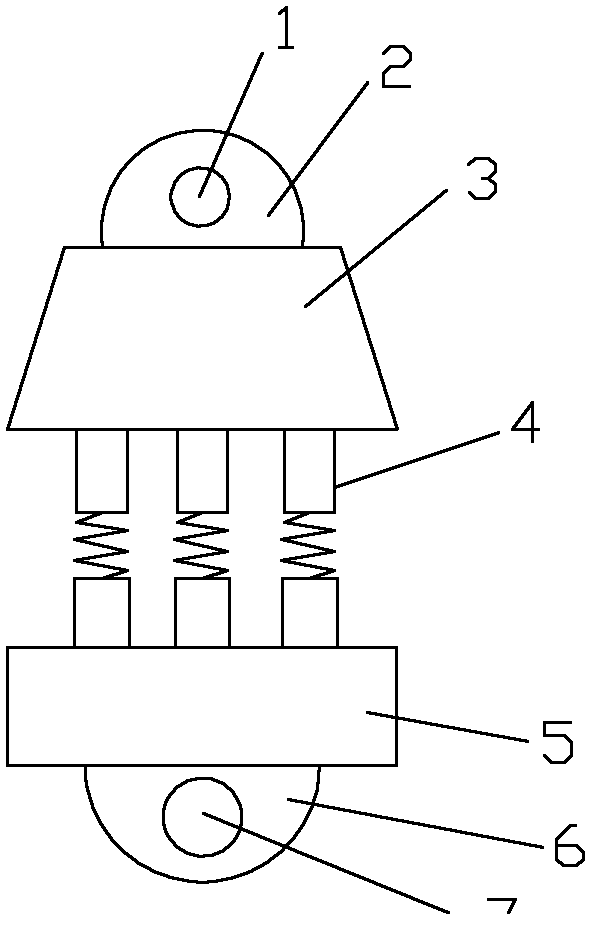

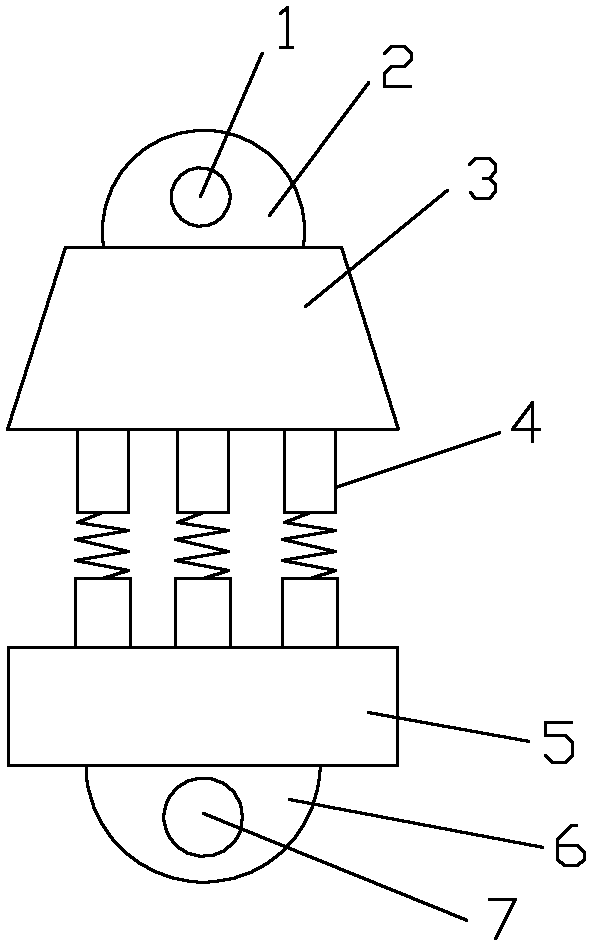

[0012] Such as figure 1 The exhaust pipe suspension mechanism shown includes a connecting truncated cone 3, the upper surface of the connecting truncated cone 3 is connected with a connecting ear 2, and the connecting ear 2 is provided with a connecting through hole 1 connected with the chassis of the automobile, and also includes a cylindrical Shaped connection block 5, a plurality of spring damping devices 4 are arranged between the cylindrical connection block 5 and the connection cone 3, the lower surface of the cylindrical connection block 5 is provided with a second connection ear 6, the first Two connection ears 6 are provided with a connection hole 7 connected with the exhaust pipe.

[0013] The spring damping device includes a first connecting rod connected to the connecting truncated cone, a second connecting rod connected to the cylindrical connecting block, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com