Hydrodynamic retarder

A hydraulic brake, non-braking technology, applied in the direction of hydraulic brakes, liquid resistance brakes, brakes, etc., can solve the problems of increased noise and bad feeling, and achieve the effect of avoiding loss and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

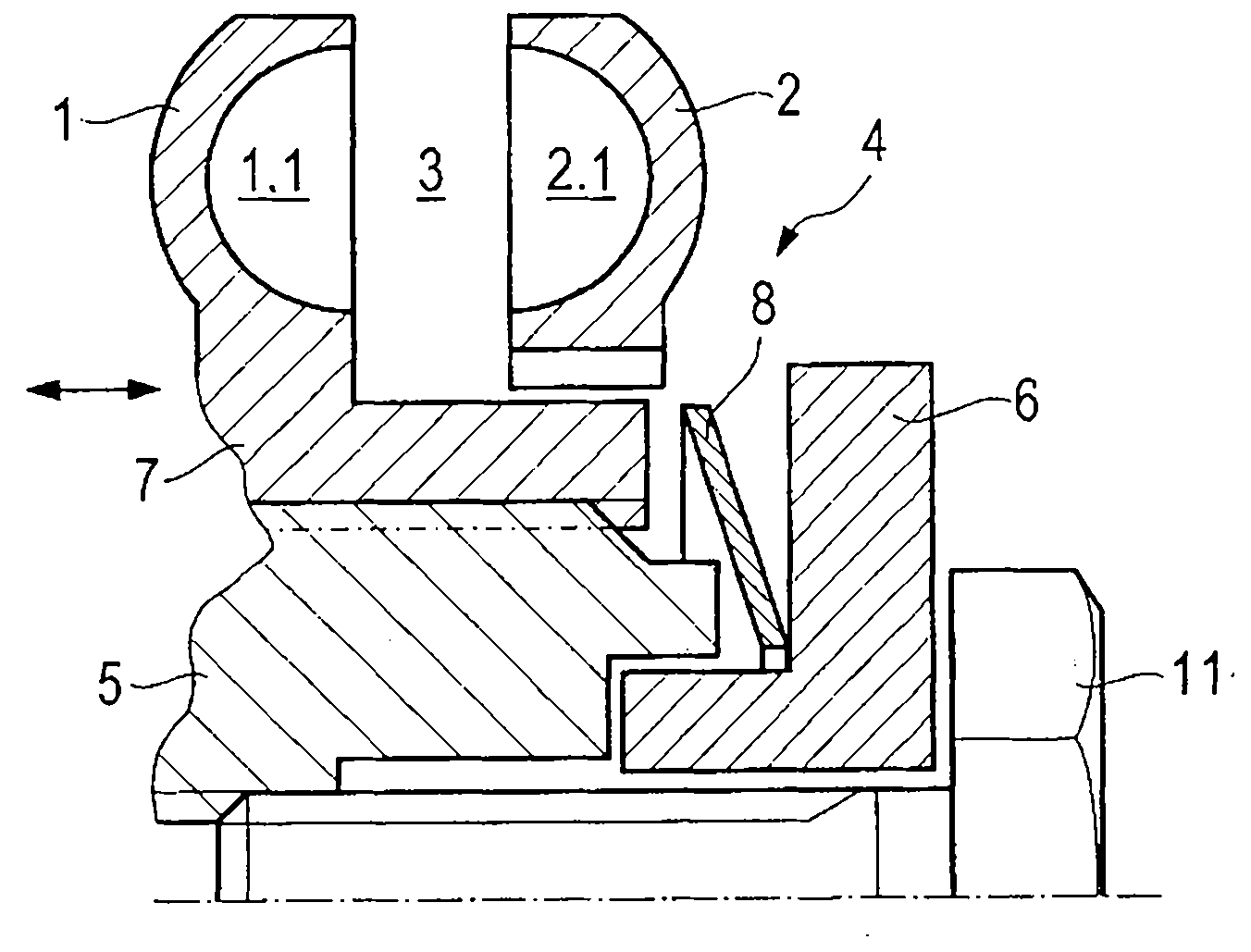

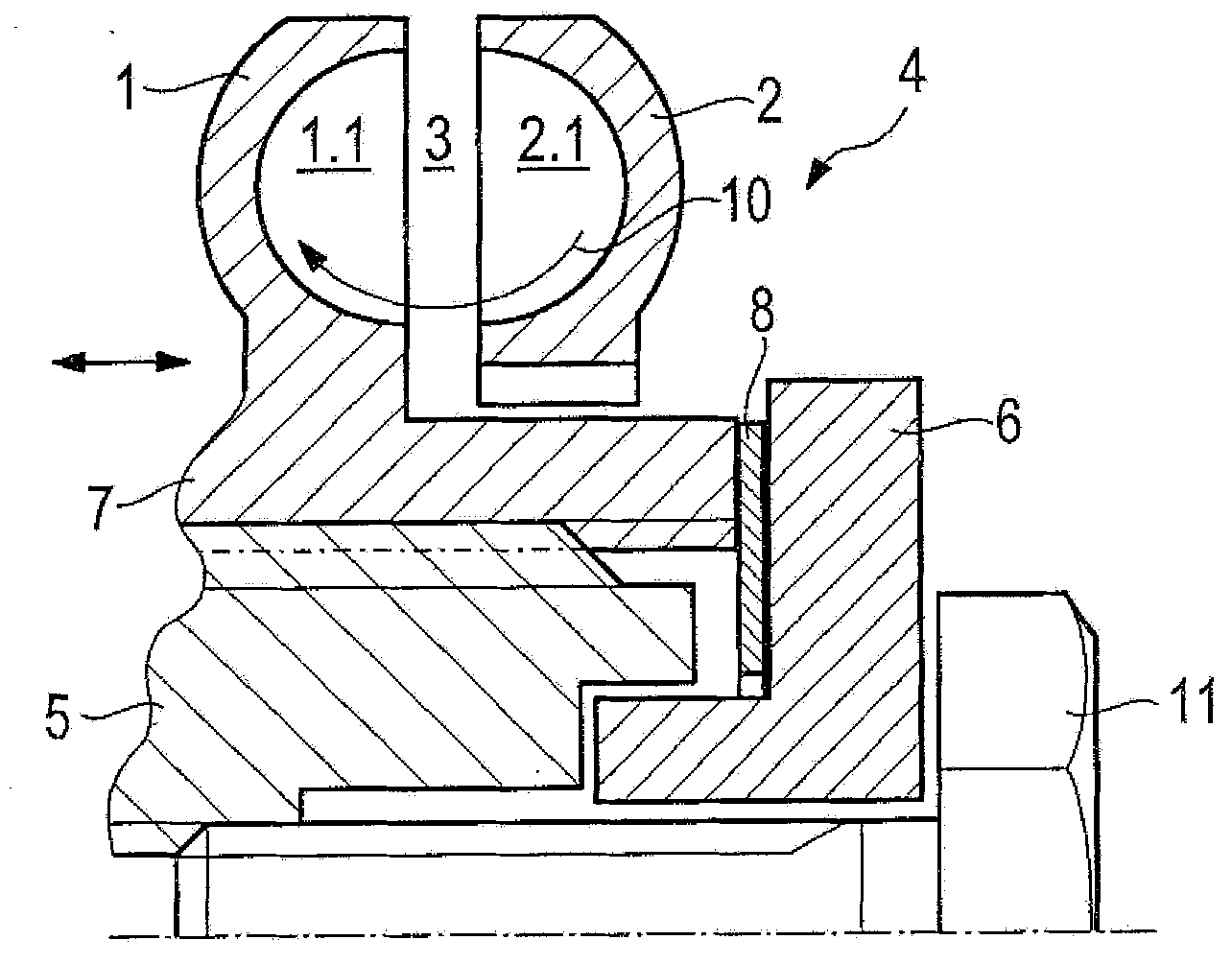

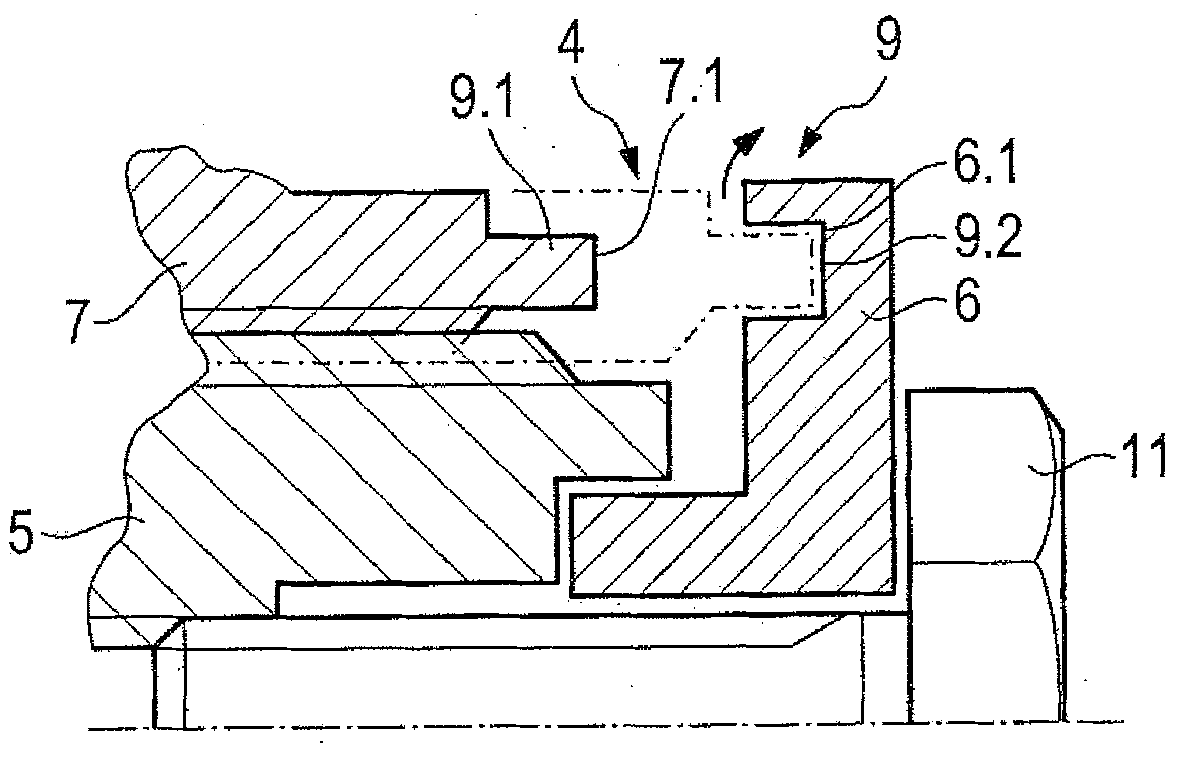

[0031] exist Figure 1a A hydrodynamic brake with a primary impeller 1 and a secondary impeller 2 is shown in . The primary impeller 1 is the rotor of the brake and the secondary impeller 2 is the stator of the brake. Both impellers 1 , 2 have a subarea with blades, ie the rotor has a subarea 1.1 and the stator has a subarea 2.1.

[0032] The stator, ie the secondary impeller 2 , can be supported by a housing (not shown), which encloses the primary impeller 1 together with the stator, for example. The impeller-mounted subregions 1.1, 2.1 of the two front impellers 1, 2 form the torus-shaped working chamber 3.

[0033] The impeller is supported by a subregion 1 . 1 of the primary impeller 1 , which is now displaceable in the axial direction of the hydrodynamic brake, as indicated by the double arrow. This axial displaceability is achieved by the fact that the primary impeller 1 is mounted on the shaft 5 by means of the hub 7 , which currently has internal teeth or an internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com