Prefabricated wall board construction member

A technology of prefabricated wall panels and components, which is applied in the direction of building components, walls, building structures, etc., can solve the problems of endangering the property and personal safety of residents, the complexity of the wall construction process, and the unreliable connection of the wall surface, etc., to reduce property and personal safety hazards, shorten construction time, and avoid time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

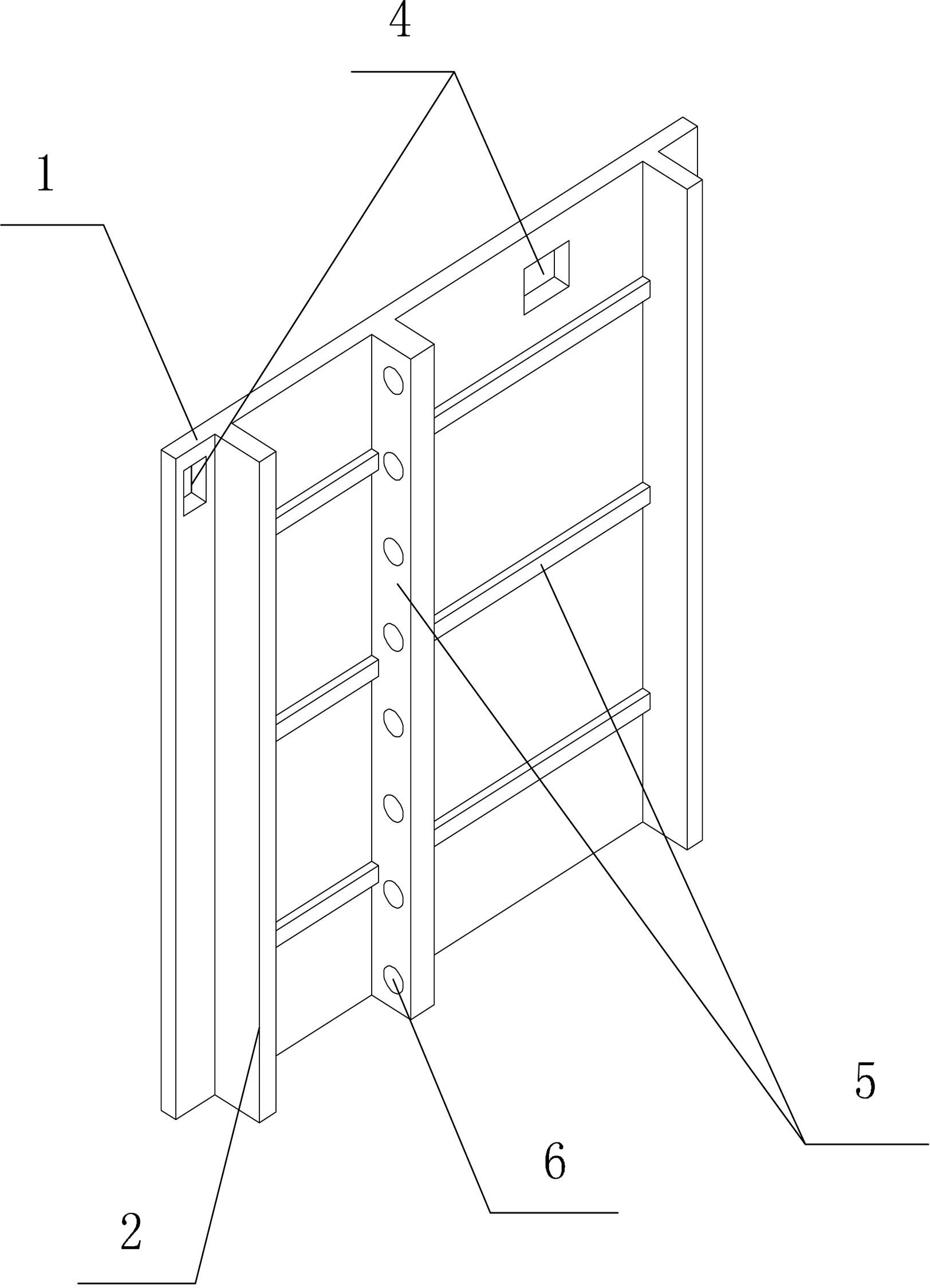

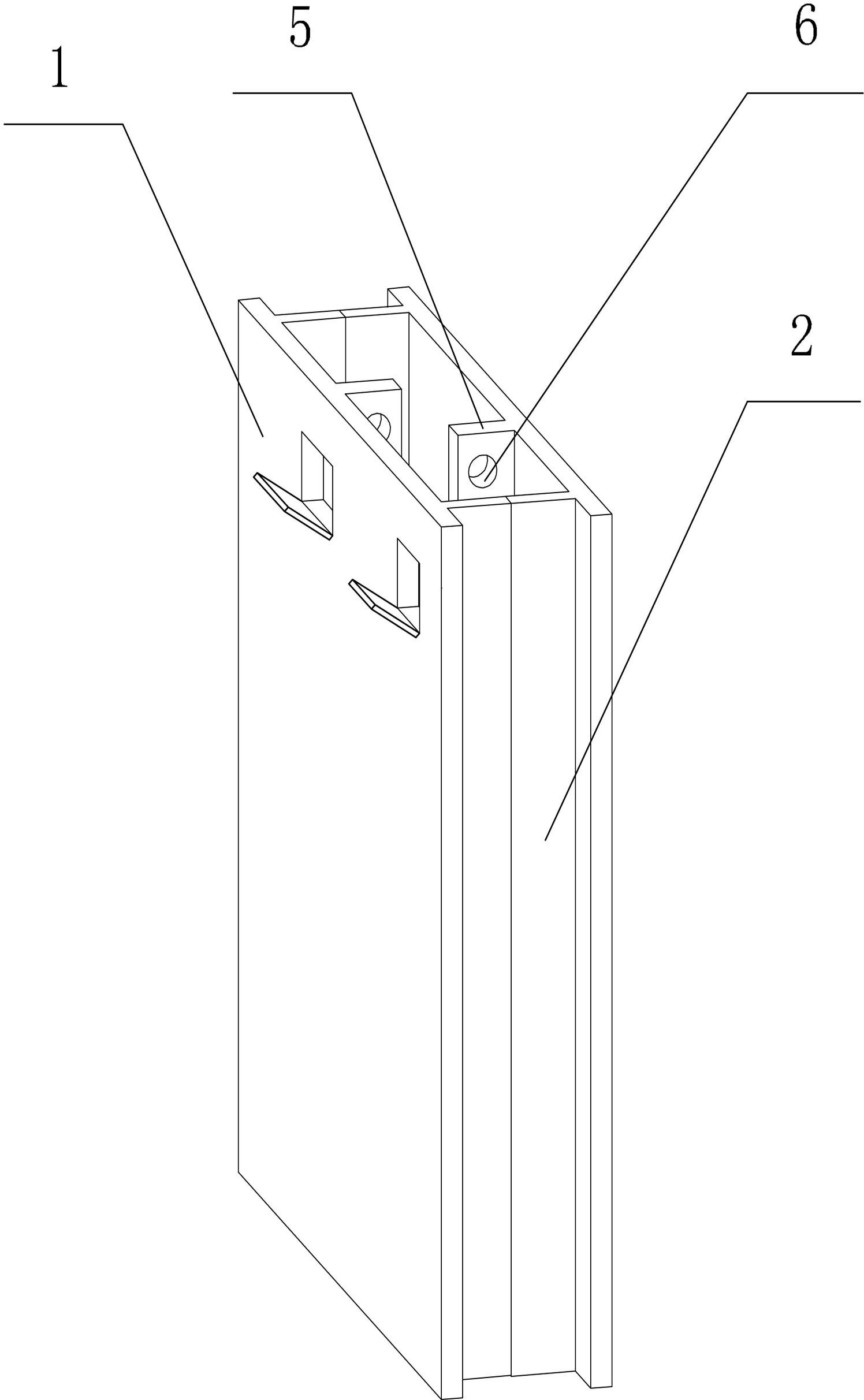

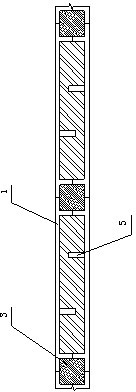

[0017] Such as figure 1 , figure 2 with image 3 As shown, a prefabricated wallboard construction component of the present invention includes two prefabricated wallboard shells 1, vertical splicing eaves 2 are arranged on opposite sides of the two wallboard shells 1, and prefabricated eaves 2 are formed between the splicing eaves 2 and their end faces. There is a space for accommodating the corresponding structural column 3, and the space between the two spliced eaves 2 and the wall panel shell 1 forms a filling wall, wherein, a wall panel shell 1 is provided at the position corresponding to the space of the structural column 3 and the space of the filling wall. There are sprues 4.

[0018] In this embodiment, in order to strengthen the rigidity of the wall panel shells 1 , the inner sides of the two wall panel shells 1 are provided with transverse and longitudinal ribs 5 . In order to keep the material of the wall consistent with the building, the wall panel shell 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com