Outer-rotor fluid power machine

An external rotor and power machine technology, applied in the field of power machinery, can solve problems such as loss of energy and inability to meet special needs, and achieve the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

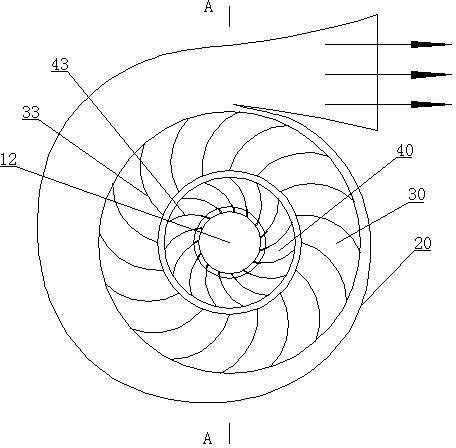

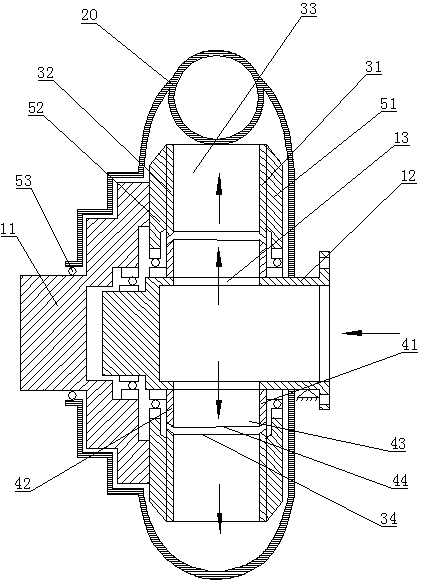

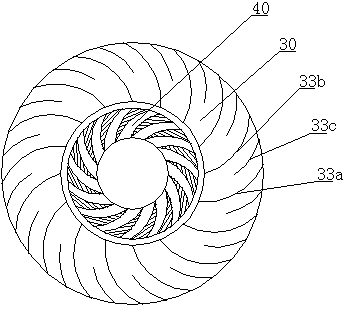

[0018] like figure 1 , figure 2 The shown impeller-type external rotor fluid power machine is mainly composed of a shaft, a casing 20, an impeller 30, and a flow guide 40. Side walls 31, 32, an annular closed impeller with blades 33 installed between the two side walls, the deflector 40 has side walls 41, 42 on both sides, and guide vanes 43 are installed between the two side walls An annular body, the impeller 30 is set on the outer circle of the deflector 40, the shaft is formed by concentrically fitting one end of a moving shaft 11 on one end of a hollow fixed shaft 12, and the deflector 40 is installed on the hollow fixed shaft 12, One end surface of the hollow fixed shaft 12 is closed, and the other end surface is provided with an inlet and communicated with the inlet pipe. The circumference of the hollow fixed shaft 12 in contact with the deflector 40 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com