Axial-radial flow multi-step feeding fixed bed reactor and paraxylene preparation method

A fixed-bed reactor, axial and radial technology, applied in chemical instruments and methods, condensation between hydrocarbons and non-hydrocarbons, organic chemistry, etc., can solve problems that have not been involved, to improve selectivity, The effect of fewer products and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

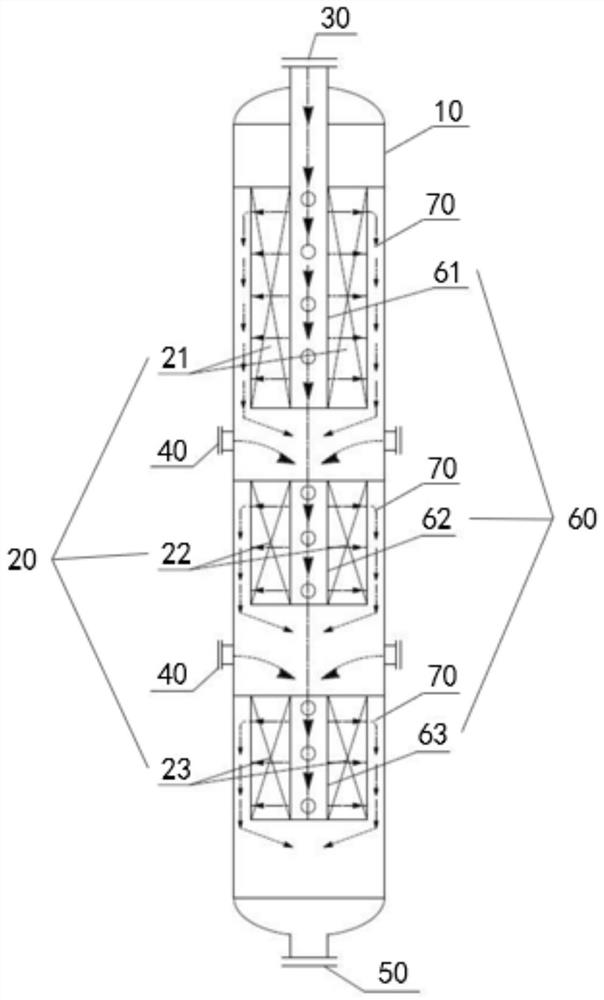

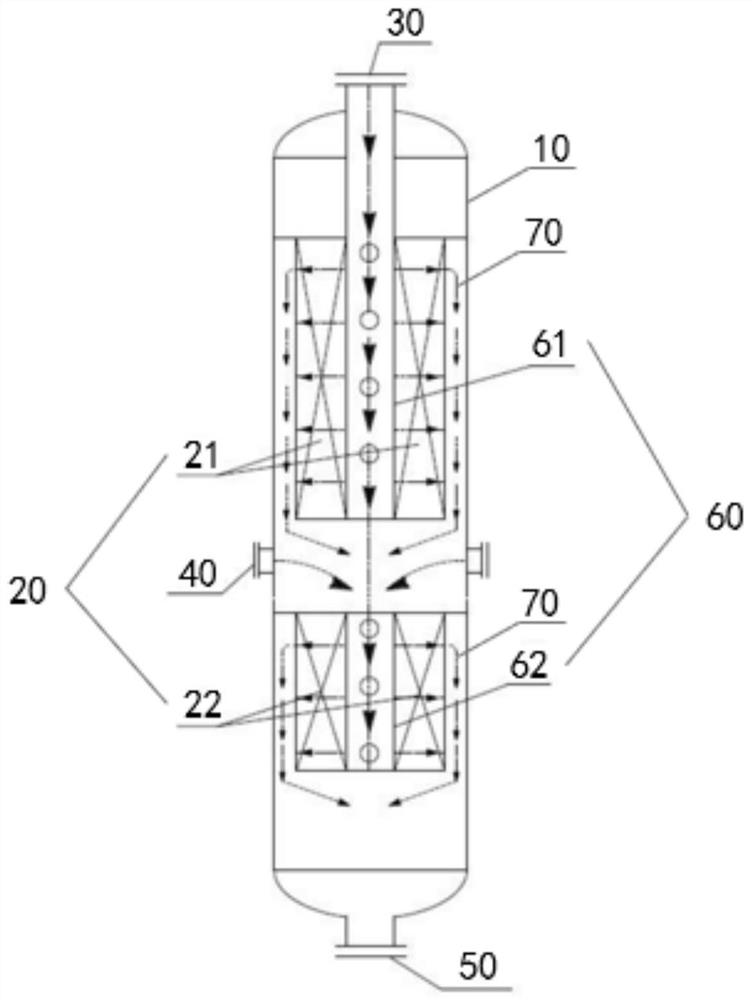

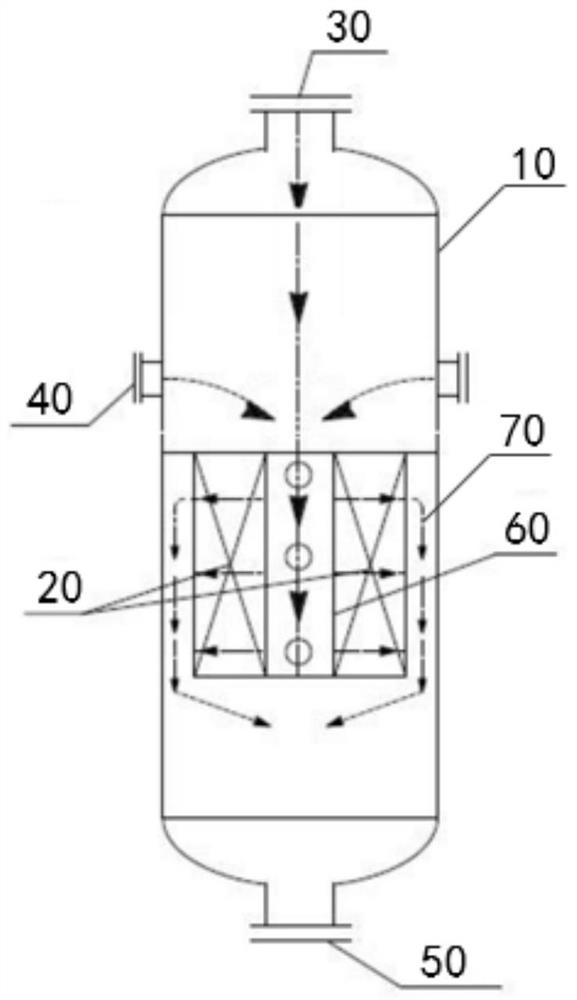

[0059] This embodiment provides a fixed-bed reactor with axial radial flow multi-step feeding, such as figure 1 As shown, the fixed-bed reactor includes a shell 10 and a three-stage catalyst bed 20 arranged inside the shell 10, and the shell 10 includes an air inlet 30, four liquid inlets 40 and 1 product outlet 50, the liquid inlet 40 is located on the side wall of the shell 10 between every two stages of catalyst beds 20, the center of the catalyst bed 20 is provided with an axial air guide pipe 60, and the axial air guide pipe 60 The ends are closed, and the side walls are evenly distributed with air outlets. The top end of the first-stage axial air duct 61 protrudes from the first-stage catalyst bed 21 and is connected to the gas inlet 30 .

[0060] In this embodiment, a gas guide area 70 is also provided between the side wall of the catalyst bed 20 and the housing 10, the top and bottom of the catalyst bed 20 are closed, and the gas guide area 70 Closed top, open bottom...

Embodiment 2

[0063] This embodiment provides a fixed-bed reactor with axial radial flow multi-step feeding, such as figure 1 As shown, the fixed bed reactor includes a shell 10 and a three-stage catalyst bed 20 arranged inside the shell 10, and the shell 10 includes one gas inlet 30, eight liquid inlets 40 and 1 product outlet 50, the liquid inlet 40 is located on the side wall of the shell 10 between every two stages of catalyst beds 20, the center of the catalyst bed 20 is provided with an axial air guide pipe 60, and the axial air guide pipe 60 The ends are closed, and the side walls are evenly distributed with air outlets. The top end of the first-stage axial air duct 61 protrudes from the first-stage catalyst bed 21 and is connected to the gas inlet 30 .

[0064] In this embodiment, a gas guide area 70 is also provided between the side wall of the catalyst bed 20 and the housing 10, the top and bottom of the catalyst bed 20 are closed, and the gas guide area 70 Closed top, open bott...

Embodiment 3

[0067] This embodiment provides a fixed-bed reactor with axial radial flow multi-step feeding, such as figure 1 As shown, the fixed-bed reactor includes a shell 10 and a three-stage catalyst bed 20 arranged inside the shell 10, and the shell 10 includes one gas inlet 30, six liquid inlets 40 and 1 product outlet 50, the liquid inlet 40 is located on the side wall of the shell 10 between every two stages of catalyst beds 20, the center of the catalyst bed 20 is provided with an axial air guide pipe 60, and the axial air guide pipe 60 The ends are closed, and the side walls are evenly distributed with air outlets. The top end of the first-stage axial air duct 61 protrudes from the first-stage catalyst bed 21 and is connected to the gas inlet 30 .

[0068] In this embodiment, a gas guide area 70 is also provided between the side wall of the catalyst bed 20 and the housing 10, the top and bottom of the catalyst bed 20 are closed, and the gas guide area 70 Closed top, open bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com