A self-fan-cooled axial flux motor with hybrid integrated centrifugal fan and axial fan

A centrifugal fan and axial flow fan technology, which is applied to electromechanical devices, electrical components, electric components, etc., can solve the problems of large axial installation size of radial flux motors, low power density and efficiency, and inability to dissipate heat away. , to achieve compact structure, improve power density and torque density, and reduce losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

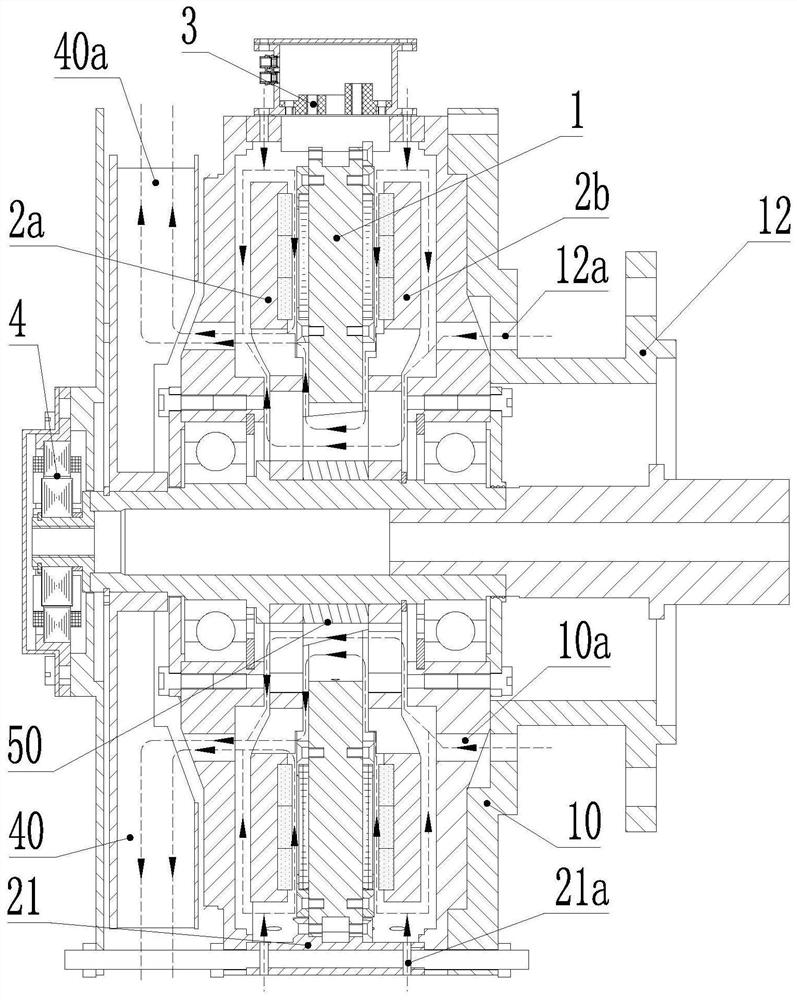

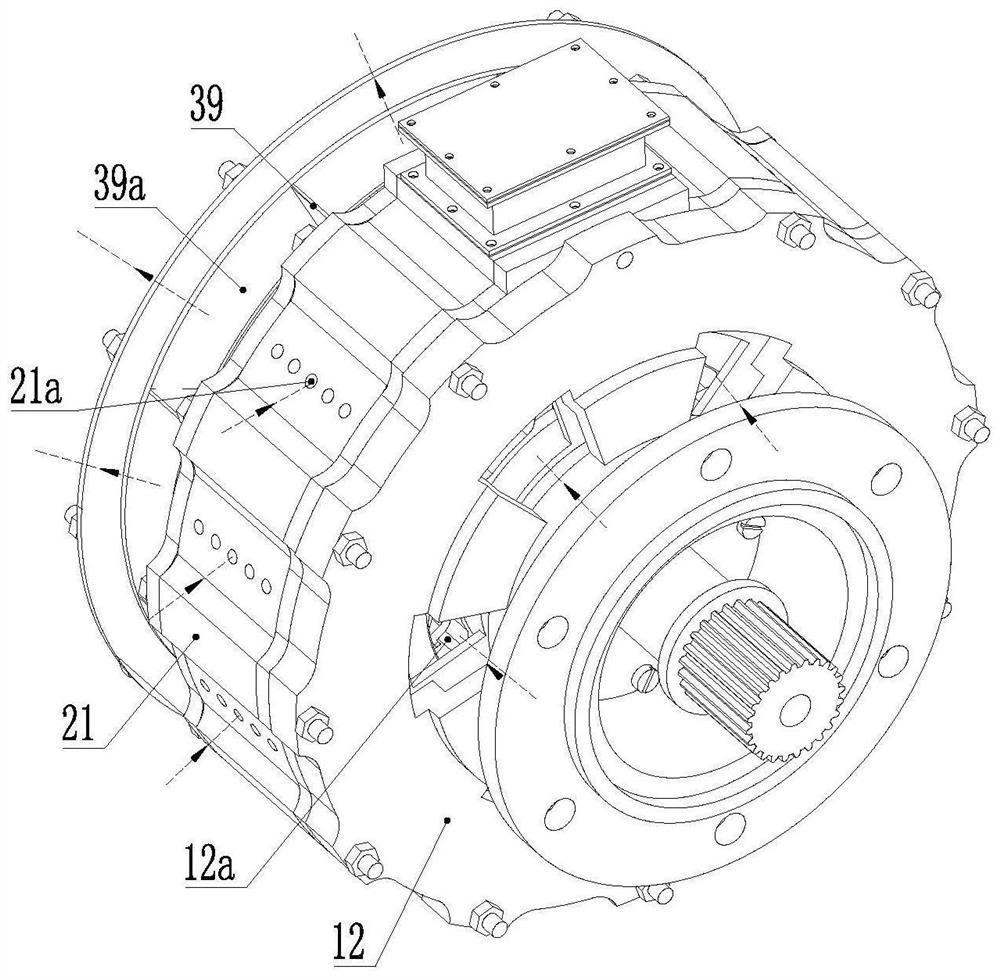

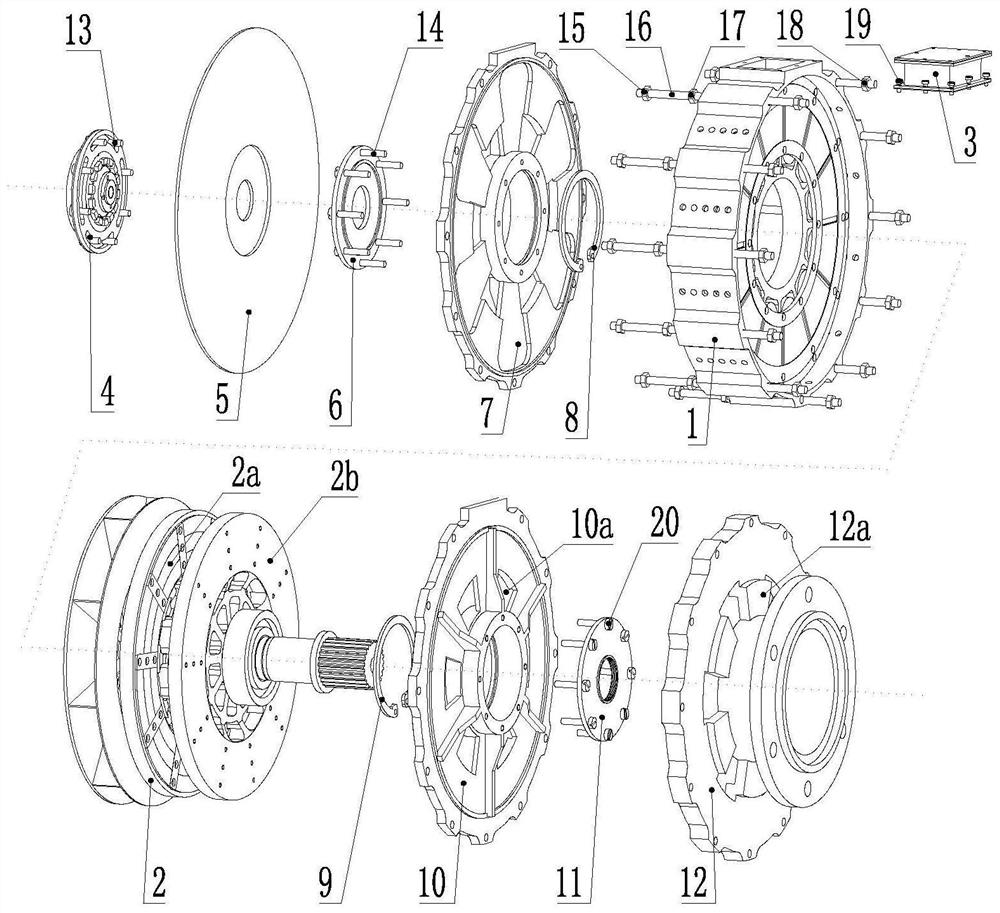

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0031]The magnetic circuit of the self-fan-cooled axial flux motor of the hybrid integrated centrifugal fan and axial flow fan runs through the stator 1 , the driving end rotor 2 b and the non-driving end rotor 2 a. The air path adopts a two-stage fan cooling scheme. Its built-in axial flow fan 50 mainly realizes one of the air path branches, which is to enter the air from the first ventilation hole 10a on the end cover 10 on the driving end side and the second ventilation hole 12a on the flange 12; the other branch , is to suck air from the ventilation hole on the driving end side of the casing 21, flow through the air gap air layer on the two side end surfaces of the driving end rotor 2b, and enter the air inlet of the axial flow fan 50. The branch circuit mainly realized by the external centrifugal fan 40 is to suck air from the vent hole on the non-drive end sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com