Automatic calibrating and compensating method of onboard mounting deflection angle of strapdown inertial navigation system

A strapdown inertial navigation and installation deflection technology, which is applied in the field of inertial navigation, can solve the problems of inconsistent heading, aircraft system attitude, heading output error, and installation error angle, etc., to achieve simple engineering use, high precision, and save the need for machinery. The effect of calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

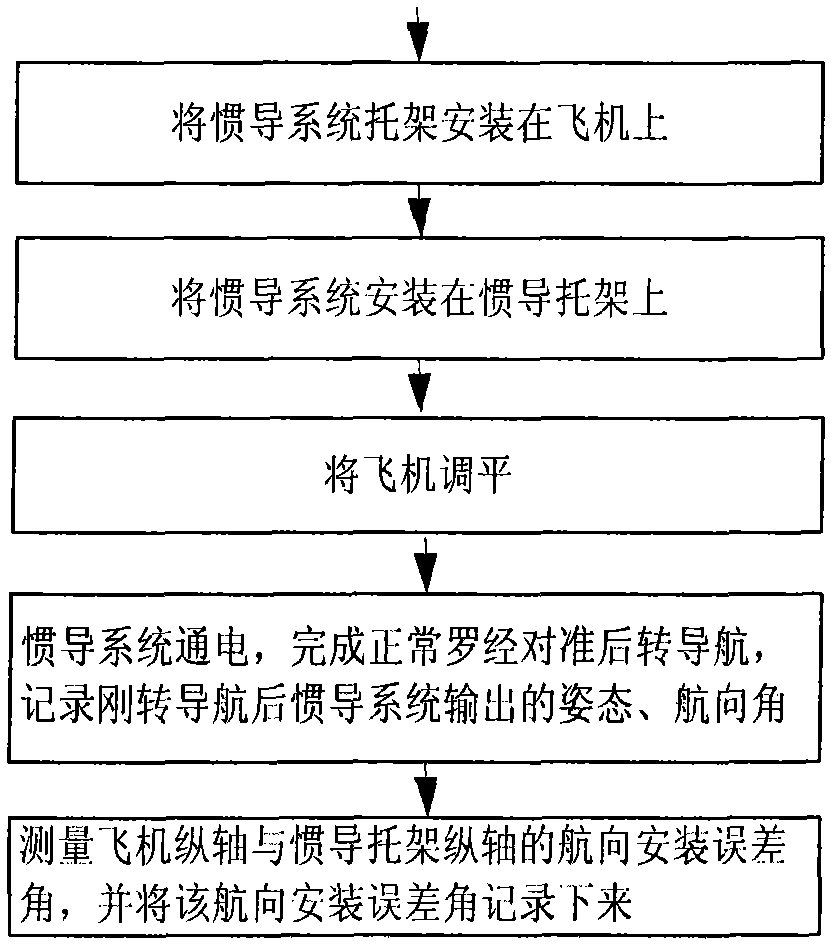

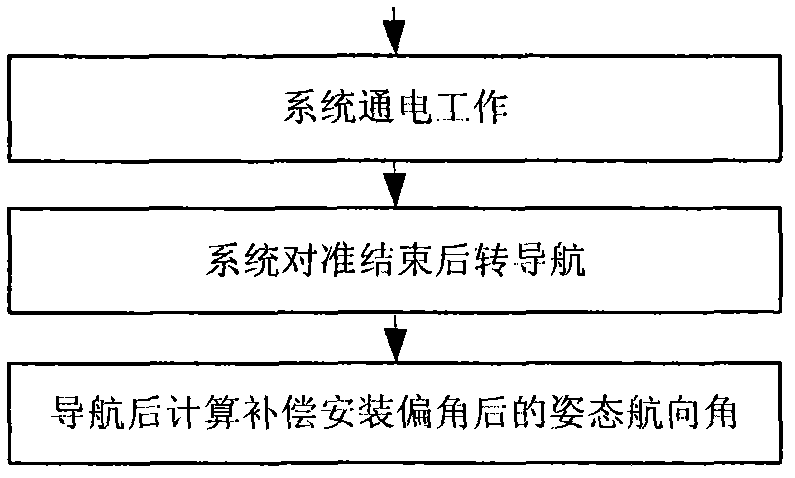

[0051] The declination calibration and compensation of the strapdown inertial navigation system installed on the aircraft are completed in two steps. The specific implementation methods of on-board installation deflection angle calibration and strapdown inertial navigation system installation deflection angle compensation will be described respectively below.

[0052] 1. Implementation method of automatic calibration of deflection angle installed on the strapdown inertial navigation system

[0053] For the automatic calibration flow chart of the on-board declination of the strapdown inertial navigation system, see figure 1 . The calibration of the installation deflection angle of the strapdown inertial navigation system is carried out on the aircraft. After the calibration is completed, the calibrated installation deflection angle is stored. As long as the inertial navigation system mounting bracket is not disassembled again, there is no need to calibrate the mounting defle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com