Patents

Literature

68results about How to "Shorten the calibration cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

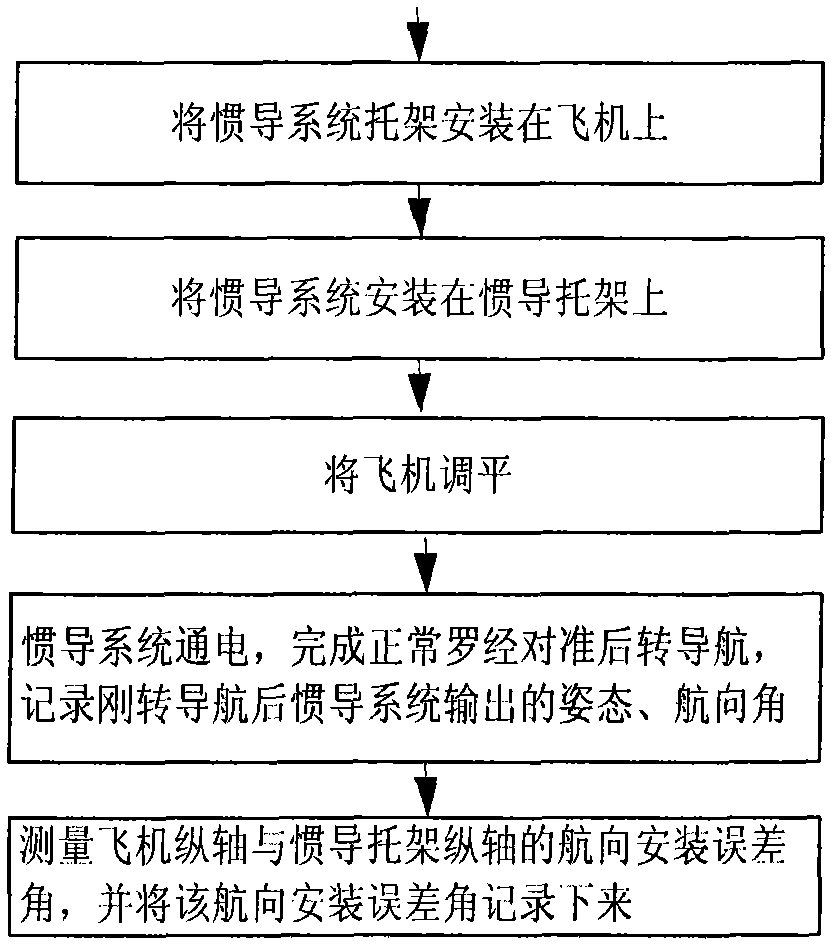

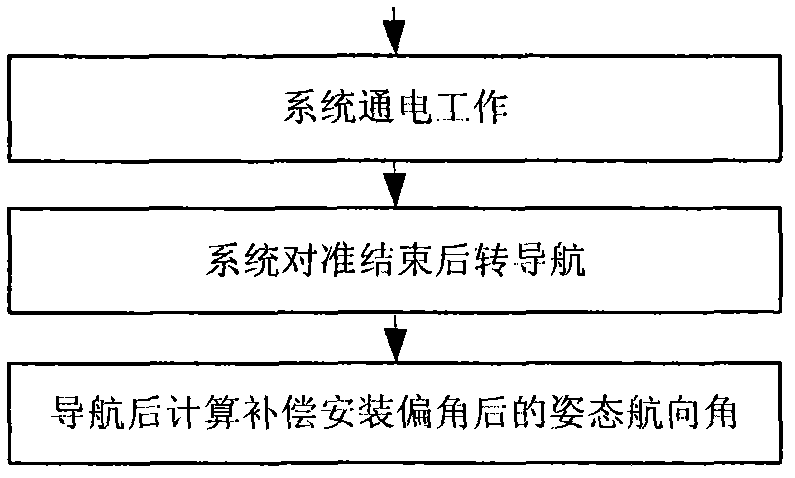

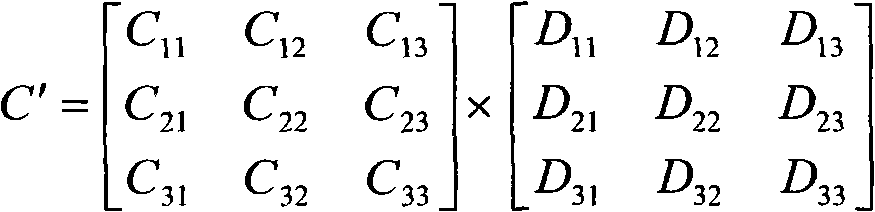

Automatic calibrating and compensating method of onboard mounting deflection angle of strapdown inertial navigation system

ActiveCN102435206AAccurate compensation of installation deflection angleEliminates the need for precise mechanical alignmentNavigation by speed/acceleration measurementsSimulationMarine navigation

The invention belongs to an inertial navigation technology, particularly relates to an automatic calibrating and compensating method of an onboard mounting deflection angle of a strapdown inertial navigation system. By using the automatic calibrating and compensating method of the onboard mounting deflection angle of the strapdown inertial navigation system, designed by the invention, only one normal compass alignment and navigation is needed after a bracket of the strapdown inertial navigation system is firstly installed on an aircraft, the posture and the heading output by the strapdown inertial navigation system are compared with the reference posture and heading, and the coordinate system of the bracket of the strapdown inertial navigation system and the mounting deflection angle of an aircraft system are automatically calibrated and are stored in a storage unit of the strapdown inertial navigation system. The mounting deflection angle is precisely compensated in the normal working process of the strapdown system through designing a mounting deflection angle compensating algorithm in strapdown inertial navigation system software, and the requirement of the aircraft for the output display and control of the posture, the heading and other navigation parameters of the strapdown inertial navigation system is met.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

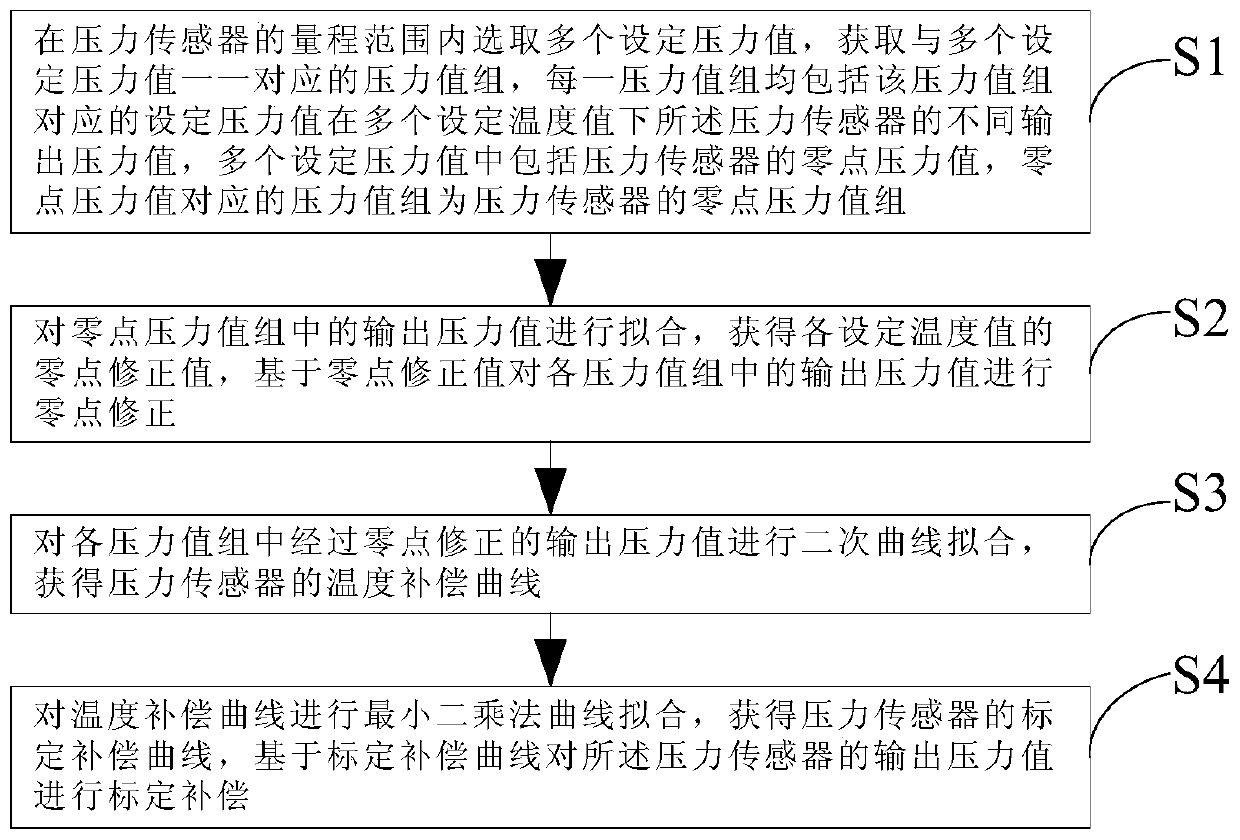

Compensation method and system of pressure sensor

ActiveCN110553786ATo achieve temperature compensationHigh compensation accuracyFlow control using electric meansFluid pressure measurementControl theoryForce sensor

The invention provides a compensation method and system of a pressure sensor. The method comprises the steps of s1, selecting a plurality of set pressure values in the measuring range of a pressure sensor, obtaining the corresponding pressure value sets, each pressure value set comprising different output pressure values under the set temperature value, and the pressure value set corresponding tothe zero pressure value being the zero pressure value set of the pressure sensor; s2, fitting the output pressure values to obtain zero-point correction values of the set temperature values, and performing zero-point correction on the output pressure values in the pressure value groups based on the zero-point correction values; s3, performing quadratic curve fitting on the output pressure value subjected to zero correction to obtain a temperature compensation curve; and s4, performing least square method curve fitting on the temperature compensation curve to obtain a calibration compensation curve of the pressure sensor, and performing calibration compensation on the output pressure value based on the calibration compensation curve. The pressure sensor compensation method and system provided by the invention are high in compensation precision, low in system resource consumption and short in calibration period.

Owner:BEIJING SEVENSTAR FLOW CO LTD

Calibration method of balance with air bridge of wind tunnel strain considering pressure influence

ActiveCN108507752AShorten the calibration cycleImprove R&D efficiencyAerodynamic testingAir bridgeAerodynamic load

The present invention provides a calibration method of a wind tunnel strain balance with an air bridge considering pressure influence. Working formulas, with a limited quantity, of a balance with an air bridge in different pressure states are employed to perform fitting and generate a general balance working formula suitable for a pressure range required by a test, and the general balance workingformula comprises pressure parameters. The pressure parameters are added into the general balance working formula of the balance with the air bridge, and when wind tunnel test is performed, an actually measurement pressure value and electrical signal increment value of each component of the balance are substituted into the general balance working formula to calculate and obtain accurate aerodynamic loading. Compared to the calculation result of a traditional balance formula, the general balance working formula can obtain more accurate aerodynamic loading so as to facilitate improvement of accuracy of the type of the wind tunnel test.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

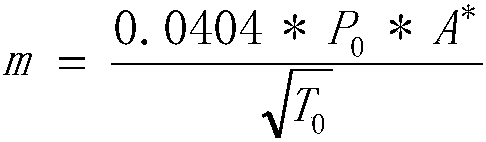

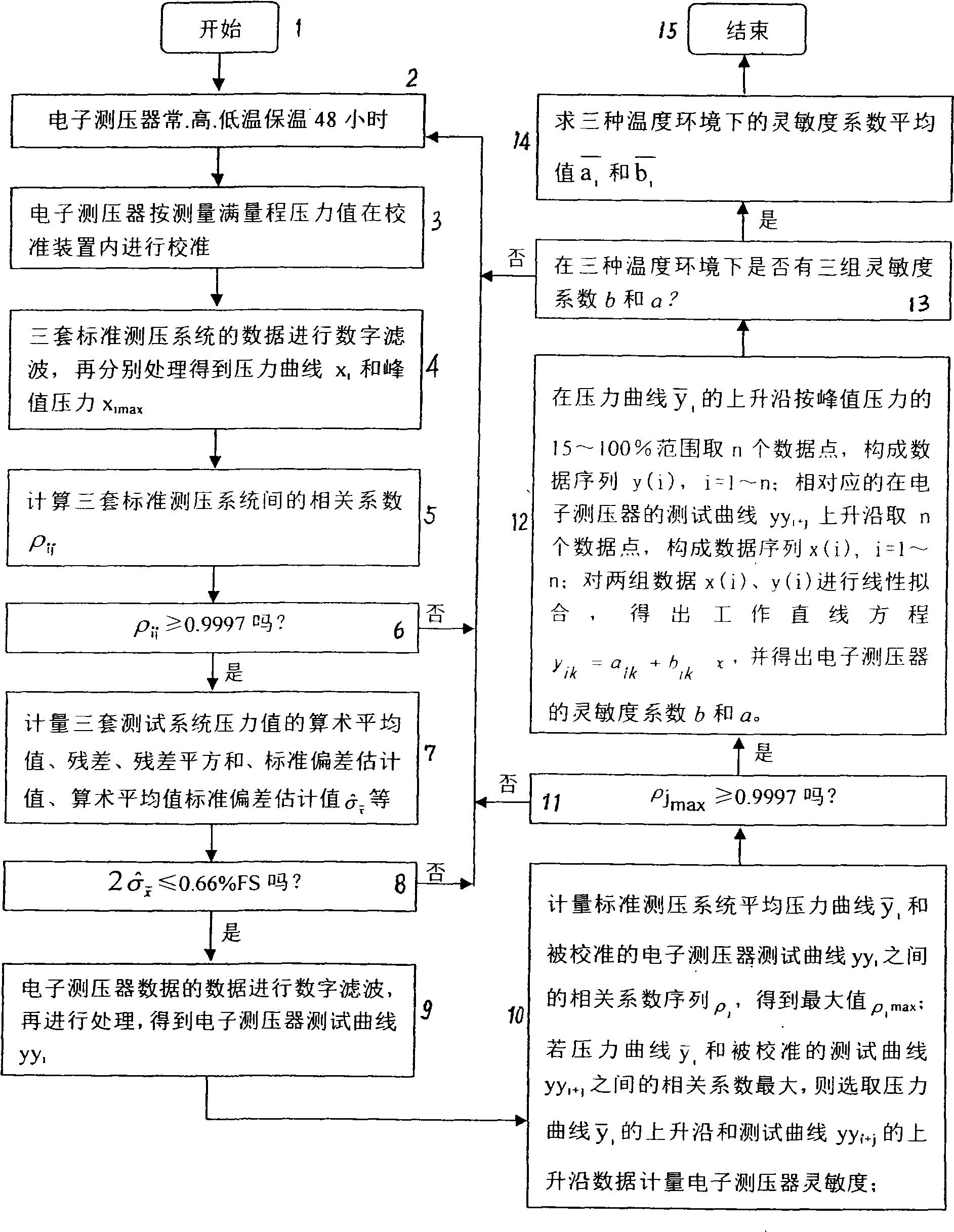

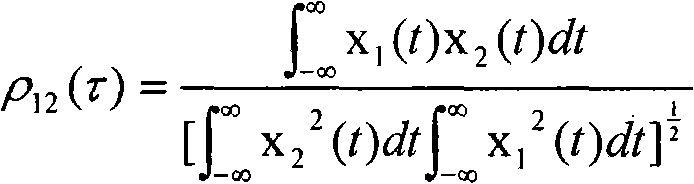

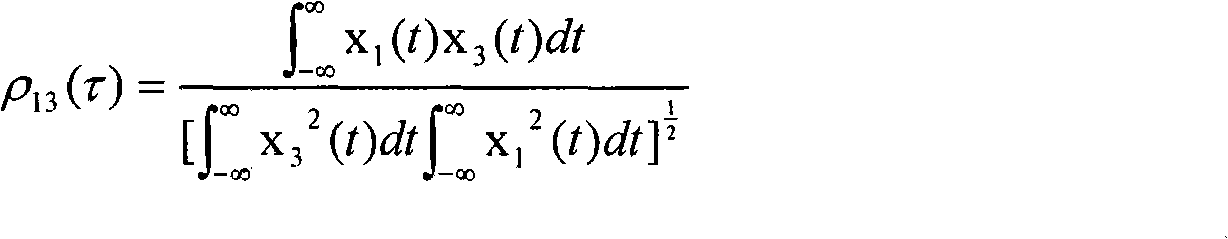

Method for metering sensitivity of electronic pressure detector

InactiveCN101334330AGuaranteed accuracyLow costFluid pressure measurementPressure curveRoom temperature

The invention relates to a method for measuring the sensitivity of an electronic manometer, which belongs to the technical field of electronic measurement. The method comprises the following steps: a pressure value with the measuring pressure of full scale is selected as base measuring pressure; dynamic calibration to the electronic manometer to be calibrated is carried out respectively under normal temperature, high temperature and low temperature environments; under the condition that three sets of standard pressure-measuring systems and the electronic manometer to be calibrated are all effectively calibrated, an average pressure curve measured by the three sets of standard pressure-measuring systems and the rising edge data of the curve measured by the calibrated electronic manometer are utilized to compute to obtain the sensitivity of calibrated electronic manometer. The method of the invention has simple operation, the calibration only needs to be carried out for three times respectively under the normal temperature, the low temperature and the high temperature, the sensitivity coefficient of the electronic manometer under the three temperature environments can be obtained by the calibration of nine times; compared with the existing measuring method, the method of the invention lowers the calibrating period, improves the working efficiency, reduces the testing expenses and the item cost, has precise and reliable result, and is the result of innovative thinking. The method for measuring the sensitivity of the electronic manometer is worthy of being adopted and generalized in the industry.

Owner:ZHONGBEI UNIV

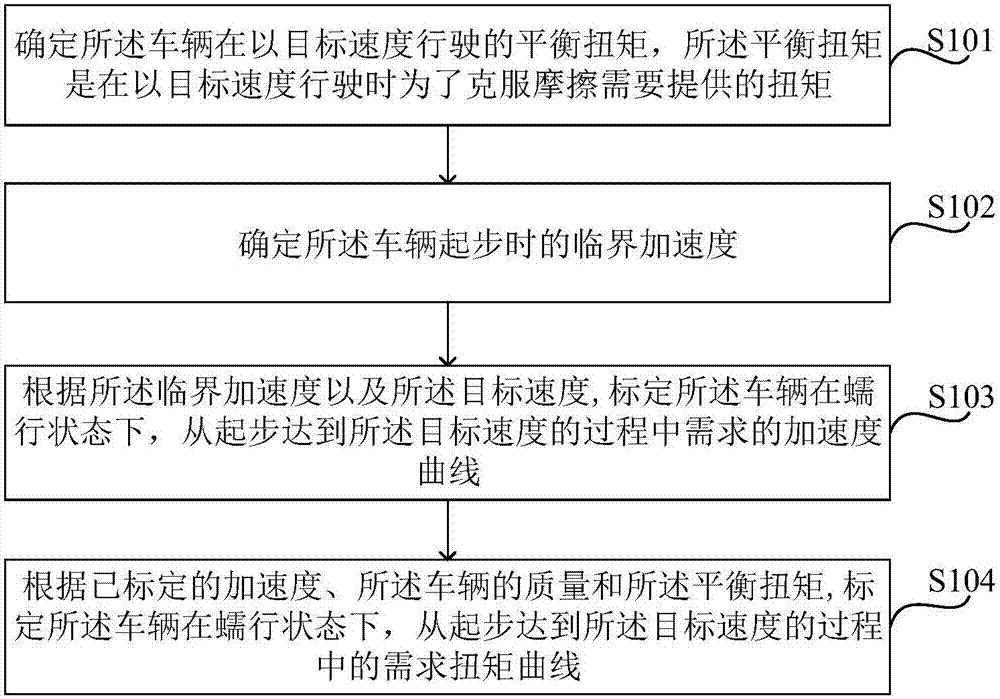

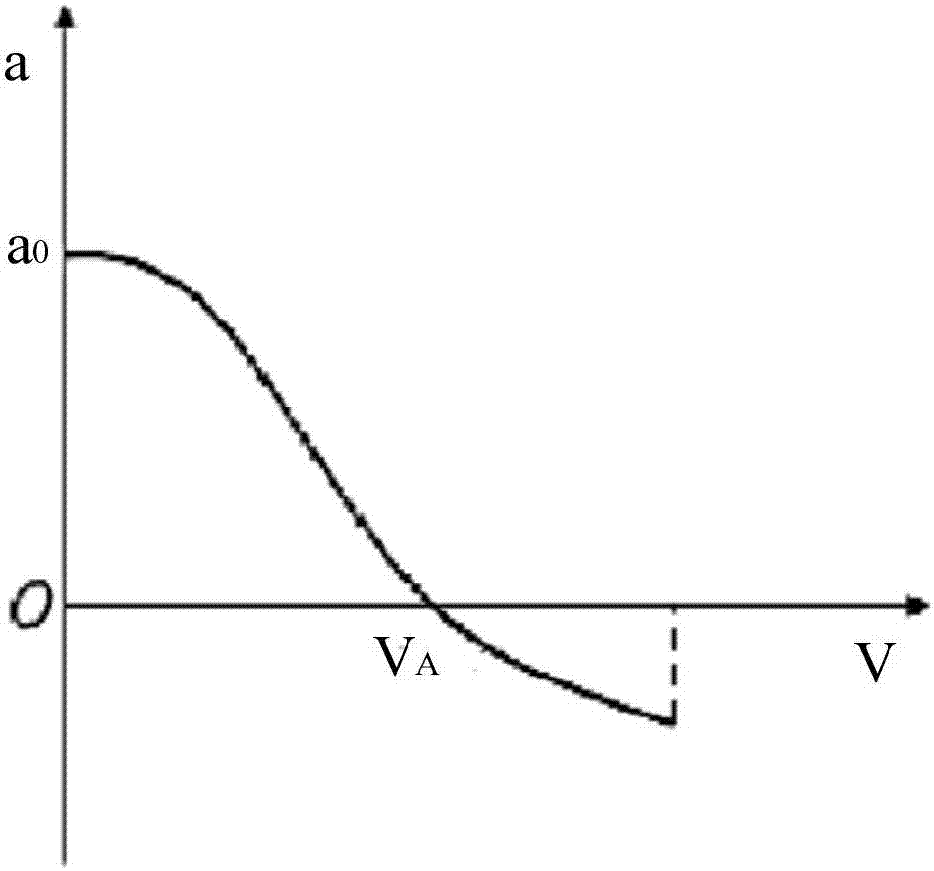

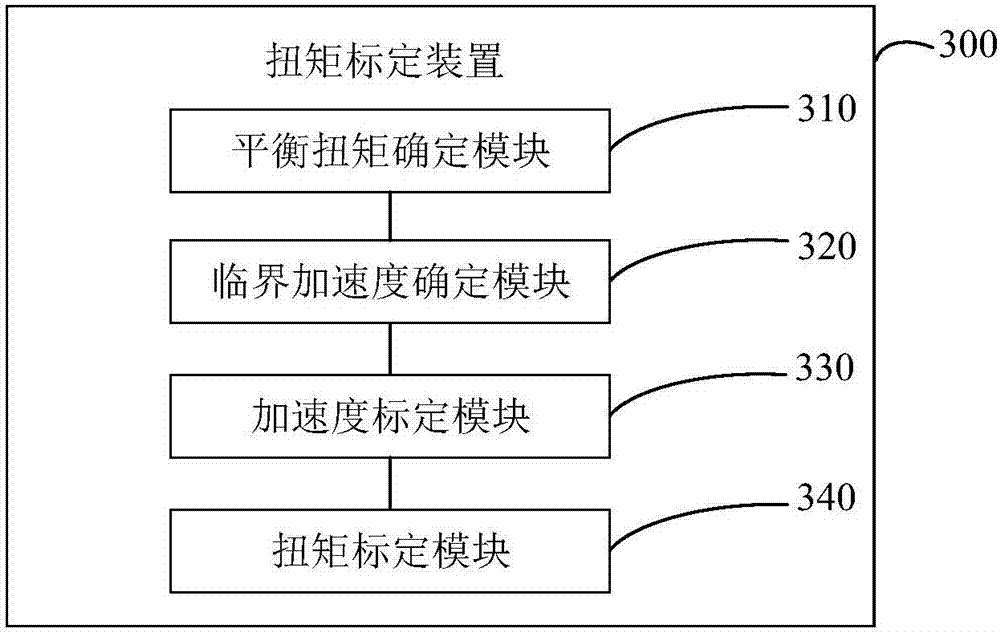

Method for calibrating vehicle demanded torque and torque calibration device

The invention provides a method for calibrating vehicle demanded torque and a torque calibration device and aims to solve the problem in the prior art that calibration of torque demanded by a vehicle worming function is difficult. The method comprises the steps that balance torque of a vehicle running at a target speed is determined, wherein the balance torque is the torque provided to overcome friction demands during running at the target speed; temporary acceleration for vehicle starting is determined; according to the temporary acceleration and the target speed, an acceleration curve demanded during the course from starting to reaching of the target speed under a vehicle worming state is calibrated; and according to the calibrated acceleration, mass of the vehicle and the balance torque, a demanded torque curve for the course from starting to reaching of the target speed under the vehicle worming state is calibrated.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

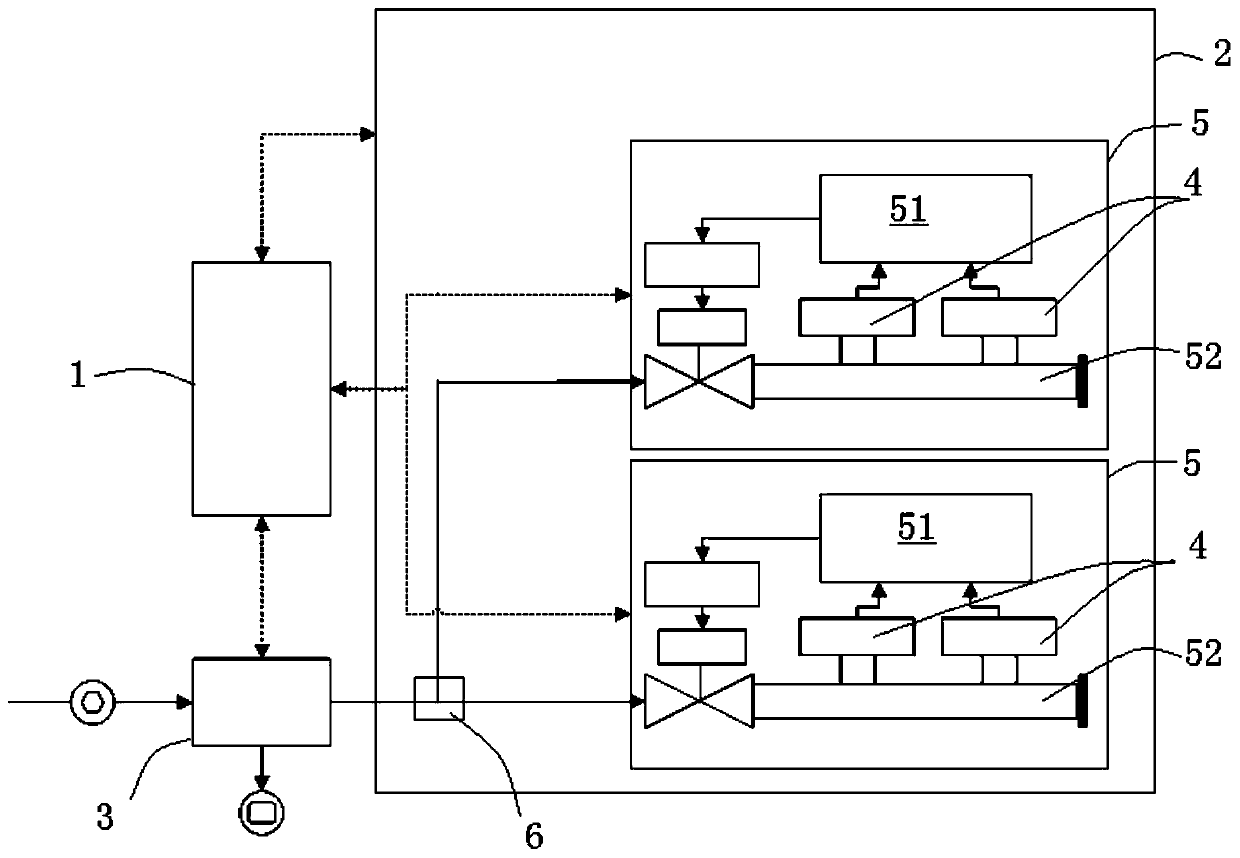

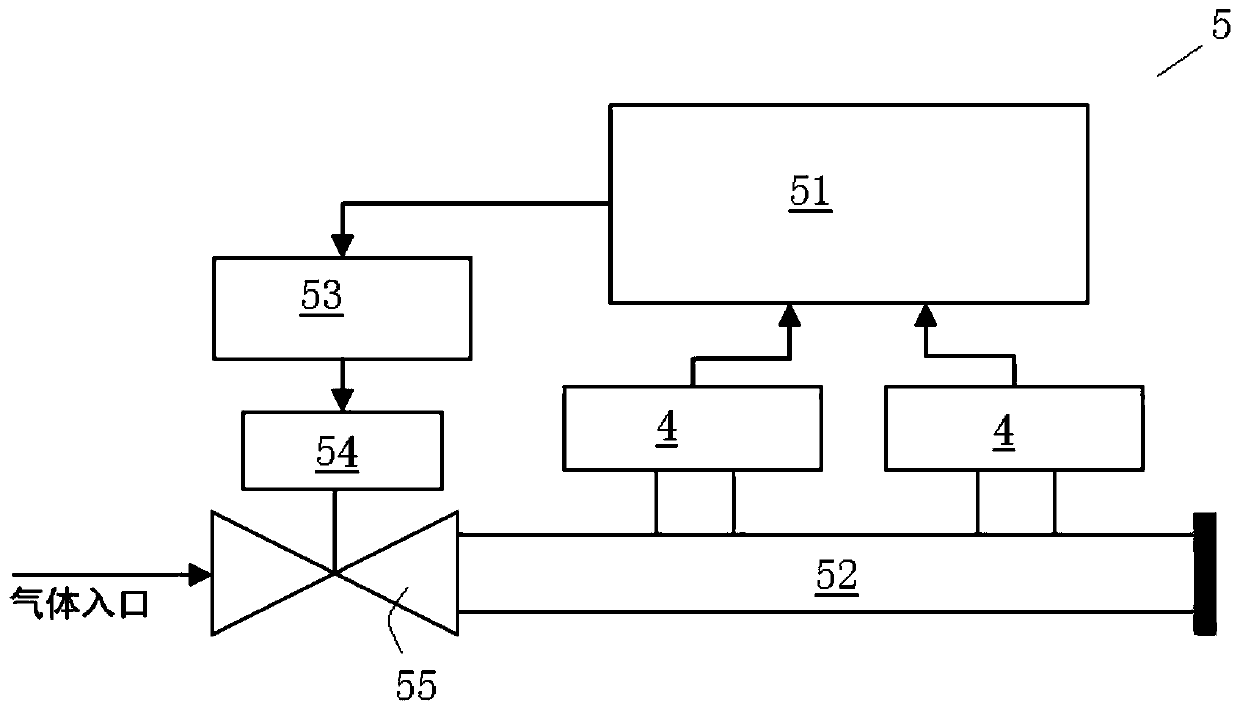

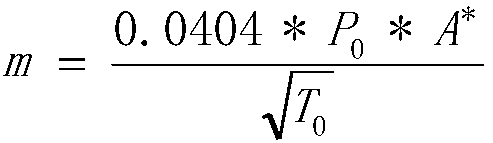

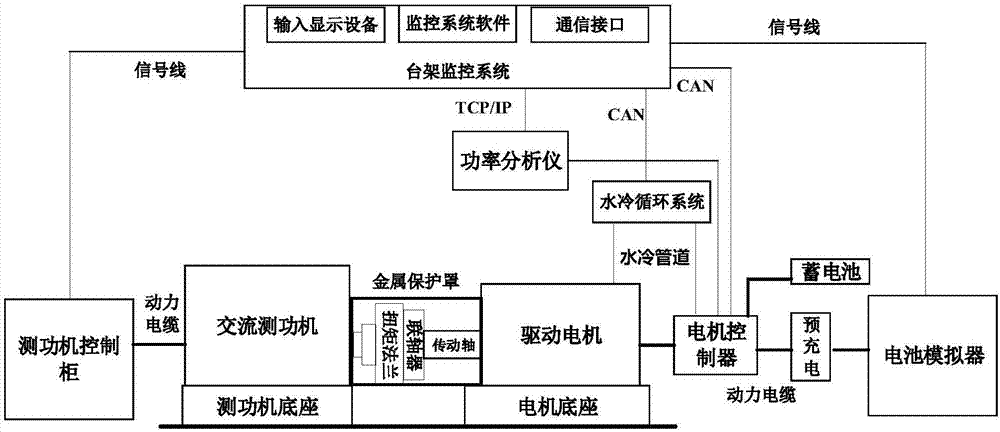

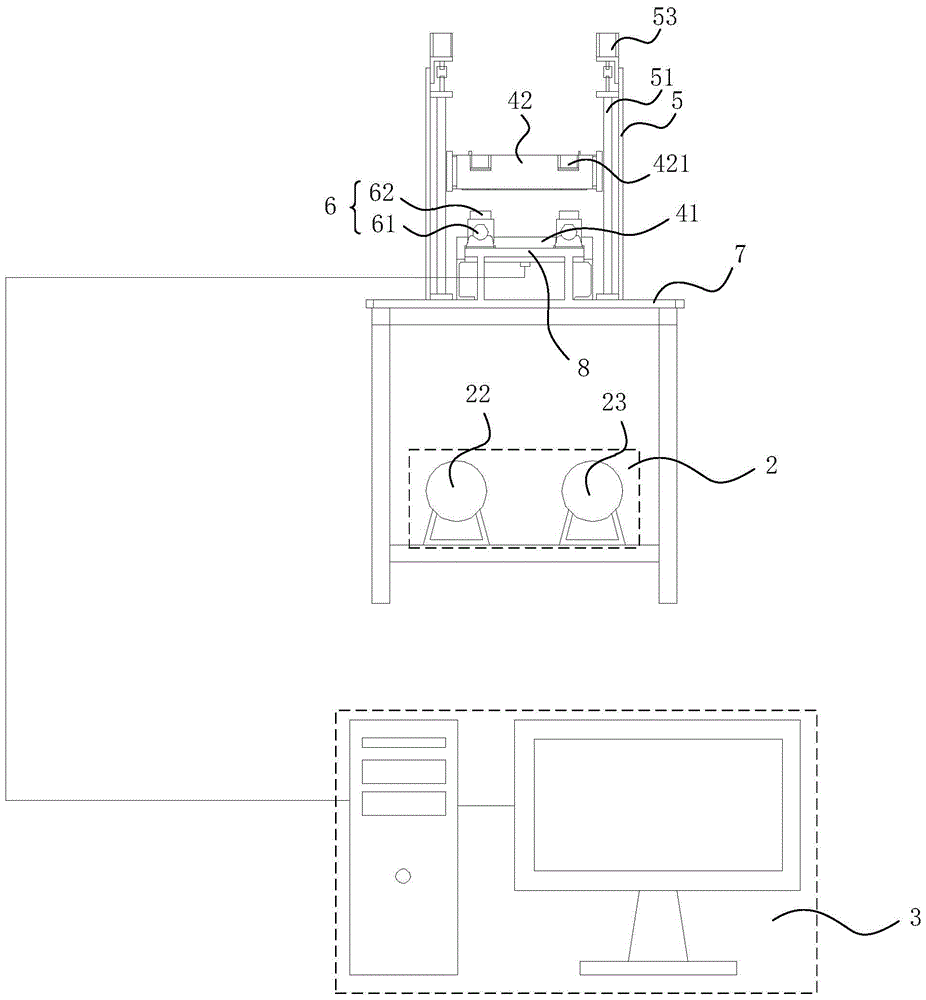

Driving motor for electric vehicle and controller calibration system and calibration method

PendingCN107272662AAvoid cumbersomeEnsure consistencyElectric testing/monitoringElectric machineDrive motor

The invention discloses a driving motor for an electric vehicle and a controller calibration system and calibration method. An alternating-current dynamometer is coaxially connected with a calibrated driving motor; the driving motor is connected with a calibrated motor controller by a power line; a motor controller is connected with a battery simulator by a direct-current bus; a water-cooled circulation system is connected with the driving motor and the motor controller by a cooling pipe; a power analyzer is connected with the motor controller; and a rack monitoring system is connected with the power analyzer, the water-cooled circulation system, a dynamometer control cabinet and the battery simulator. Therefore, the testing flow is optimized, the calibration cycle is shortened, and the comprehensive utilization rate of the calibration test rack is improved. The driving motor for an electric vehicle and the controller calibration system and calibration method can applied in technical and research and development fields of electric vehicle drive motor and controller manufacturing and matching optimization widely with great promotion values.

Owner:SHANDONG UNIV

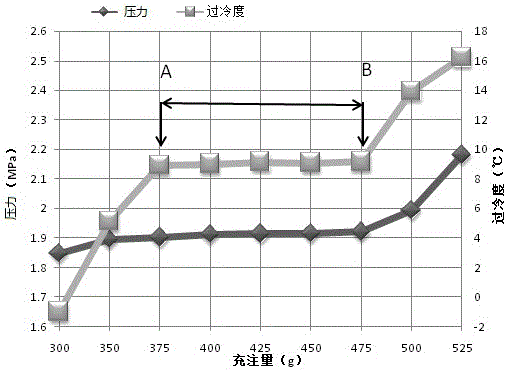

Automobile air conditioner refrigerant charge quantity calibration method

InactiveCN106198043AShorten the calibration cycleHigh precisionVehicle testingInlet temperatureRefrigerant

The invention discloses an automobile air conditioner refrigerant charge quantity calibration method. First of all, an accurate environment simulation chamber used for simulating an actual operation state of a vehicle, a refrigerant recovery charge machine used for recovering and charging a refrigerant and a data acquisition instrument used for acquiring temperature and pressure data are provided; the vehicle is fixed in the accurate environment simulation chamber, the vehicle is enabled to run under a preset working condition, a fixed quantity of the refrigerant is charged every preset time, and condenser outlet pressure, condense outlet temperature, each air outlet temperature of a blowing surface in the vehicle and an external circulation inlet temperature are respectively acquired through the data acquisition instrument; and a relation curve between a condenser outlet subcooling degree and the condenser outlet pressure and a refrigerant charge quantity is drafted, and then, an optimal refrigerant charge quantity of an air conditioner system is obtained through calculation. The automobile air conditioner refrigerant charge quantity calibration method can obviously shorten the calibration period and improves the accuracy of refrigeration calibration to a quite large degree.

Owner:HENAN NORMAL UNIV

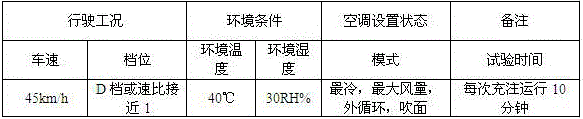

Voltage transformer online verifying system based on SF6 parallel-plate capacitor

ActiveCN104375112ASimplify the verification processShorten the calibration cycleElectrical measurementsShielded cableCapacitance

The invention provides a voltage transformer online verifying system based on an SF6 parallel-plate capacitor. The system comprises a primary voltage sensing unit, a digitalization collecting unit, an optical signal processing unit and an intelligent processing unit. The system is characterized in that the primary voltage sensing unit adopts the SF6 parallel-plate capacitor as a voltage sensing unit and obtains primary voltage signals by detecting currents in capacitance; the primary voltage sensing unit is connected or disconnected with a primary wire through a lifting platform, so that online obtaining of high-voltage signals is achieved; output of the primary voltage sensing unit is connected with the digitalization collecting unit through a shield cable; output of the digitalization collecting unit is digital quantity optical signals transmitted to the intelligent processing unit of the lower-voltage side through the optical signal processing unit. The SF6 parallel-plate capacitor is adopted as a standard mutual inductor, so that online obtaining of the high-voltage signals is achieved. Along with increase of voltage classes, the size and the weight are not increased much, and the system is light due to gas insulation and suitable for a transformer substation site.

Owner:湖北宜电电气有限公司

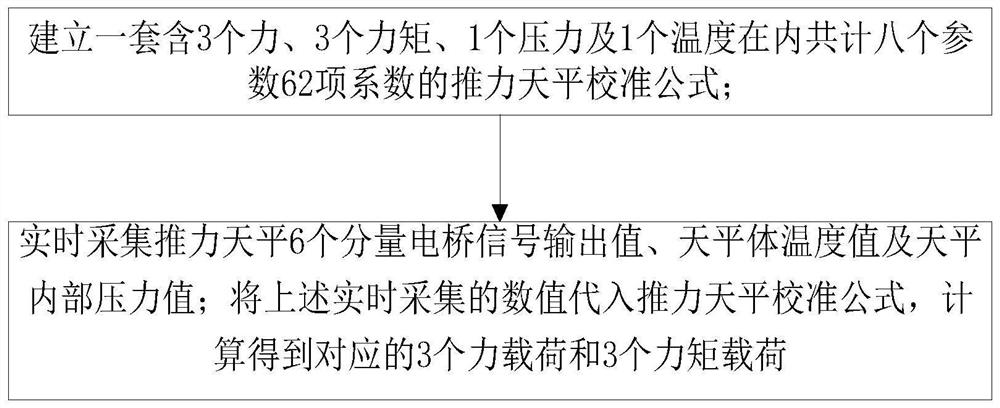

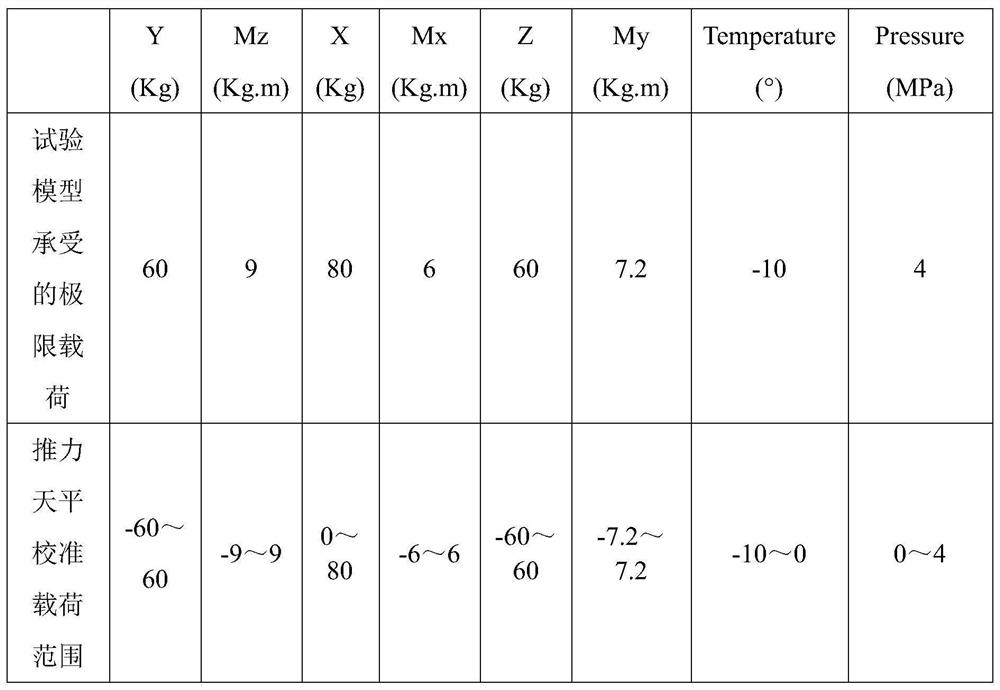

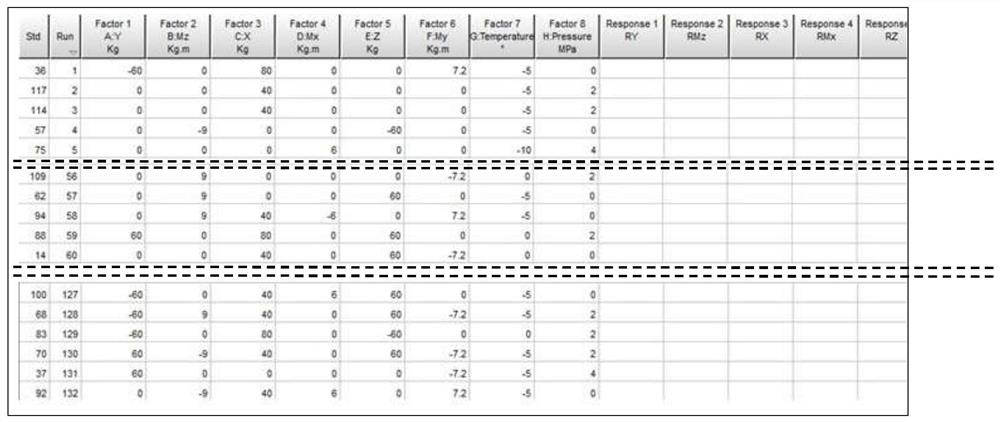

Thrust balance multivariate calibration method capable of completely simulating test state

ActiveCN112903235AQuality improvementAvoid measurement errorsSustainable transportationAerodynamic testingInternal pressureMultivariate calibration

The invention discloses a thrust balance multivariate calibration method capable of completely simulating a test state. The method comprises the following steps: acquiring six component bridge signal output values of a thrust balance, a balance body temperature value and a balance internal pressure value in real time; and substituting the values acquired in real time into a pre-established thrust balance calibration formula, and calculating and obtaining corresponding three force loads and three moment loads, wherein the thrust balance calibration formula is a relational expression between each component bridge signal of the thrust balance and three forces, three moments, one pressure and one temperature applied to the thrust balance, and totally comprises 62 coefficients. According to the method, the loaded condition of the thrust balance in the test process can be completely simulated in the calibration stage, so that the calibration state is completely consistent with the actual use state, the measurement error caused by incomplete or inconsistent simulation calibration elements is avoided, the fine measurement level of the balance of the type is improved, and the data quality of the wind tunnel test can be greatly improved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

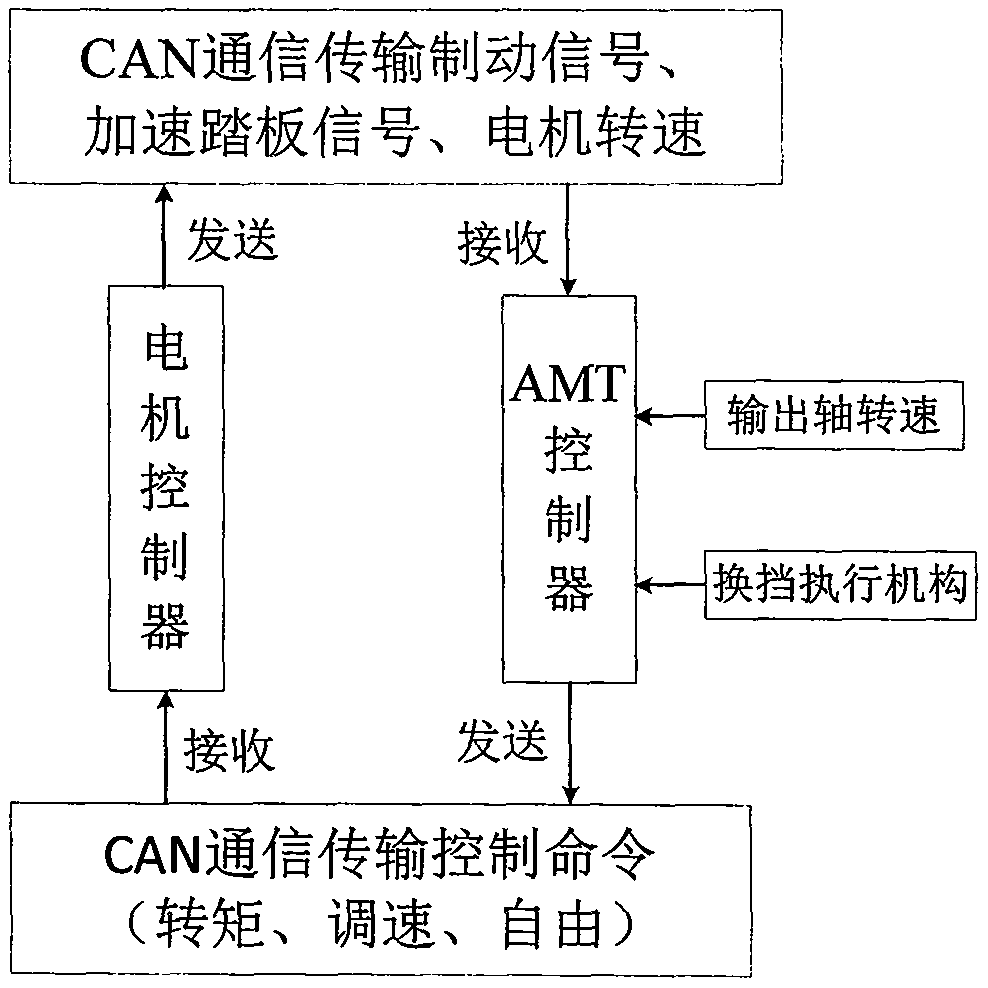

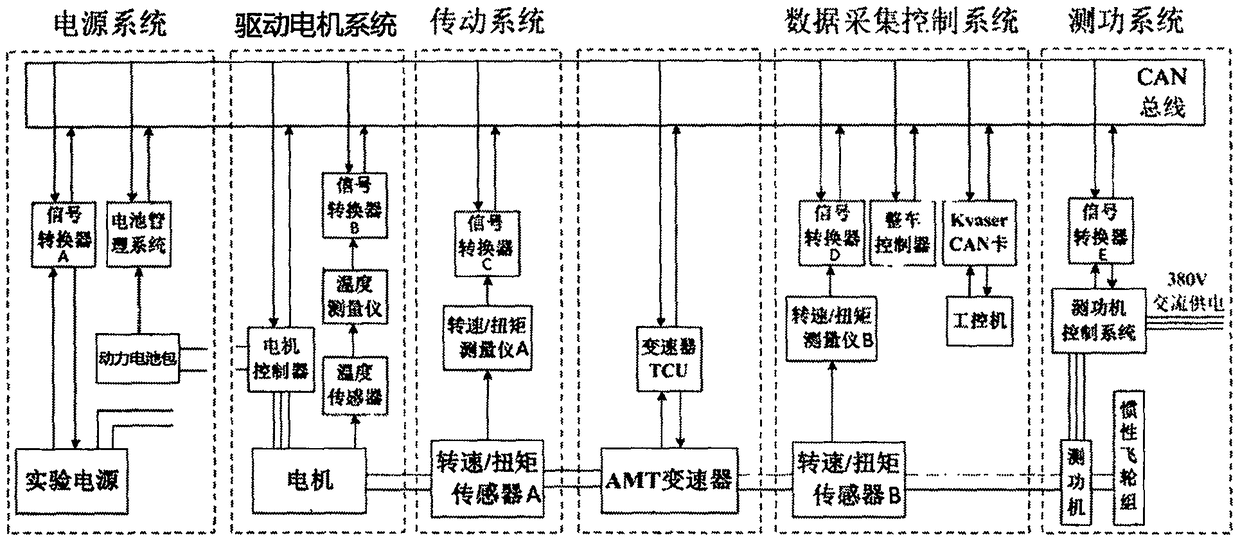

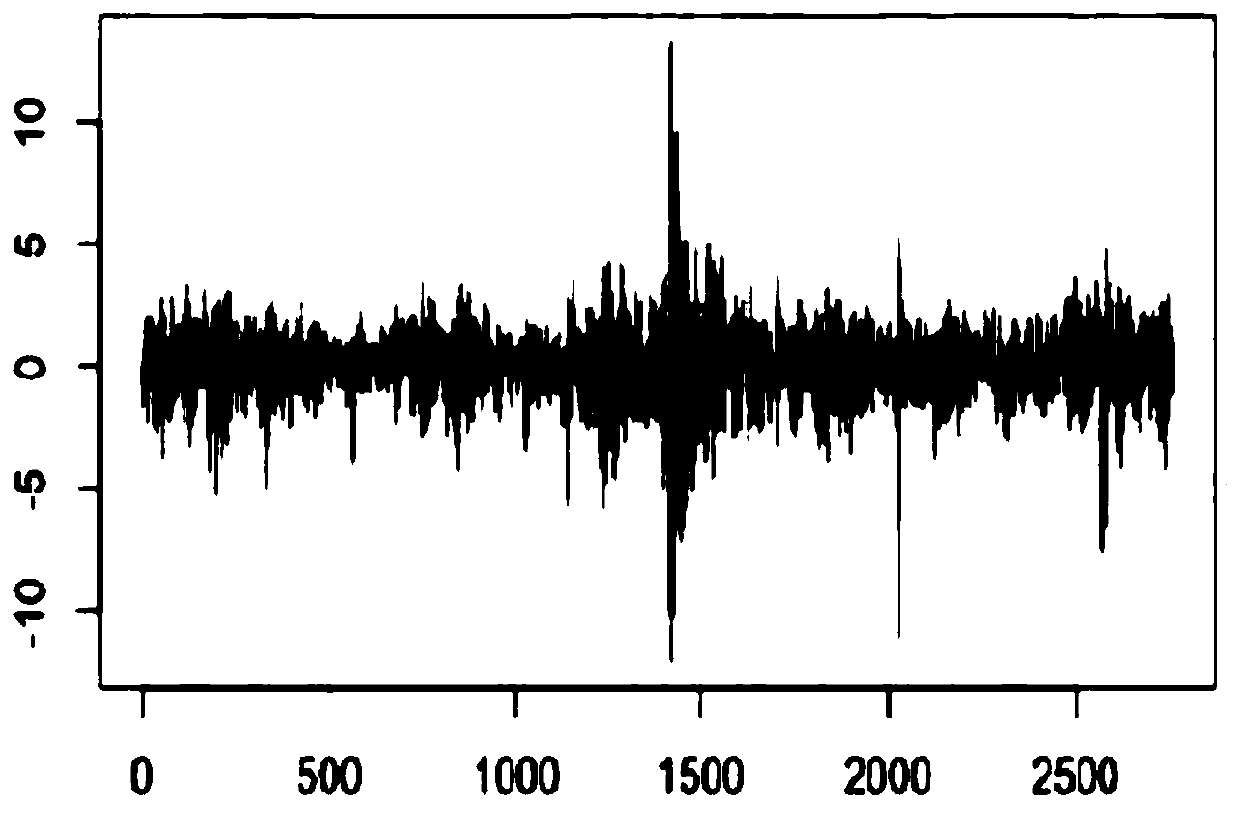

AMT automatic gearbox power transmission system assembly testing platform

InactiveCN109470958AShort cycleReduce costs and risksMachine gearing/transmission testingTesting electric installations on transportAutomotive engineeringControl system

The invention discloses an AMT automatic gearbox power transmission system assembly testing platform. The AMT automatic gearbox power transmission system assembly testing platform comprises a power supply system, a driving motor system, a transmission system, a power measurement system and a data collection control system, wherein the power supply system comprises a power battery pack and a testing power supply, the power battery pack or the testing power supply is connected with a battery management system through a power line, and then a communication way is transformed into CAN total communication through a signal conversion device A. The driving motor system comprises a motor. By means of the AMT automatic gearbox power transmission system assembly testing platform, an advanced, seriesand high-performance electric vehicle is developed, a complete perfect full electric vehicle development process is built, and the solution that the an AMT gearbox is mounted on the electric vehicleis provided. Therefore, the vehicle testing and calibration periods are shortened, and the electric vehicle development risk and cost are reduced.

Owner:HUNAN UNIV OF SCI & TECH

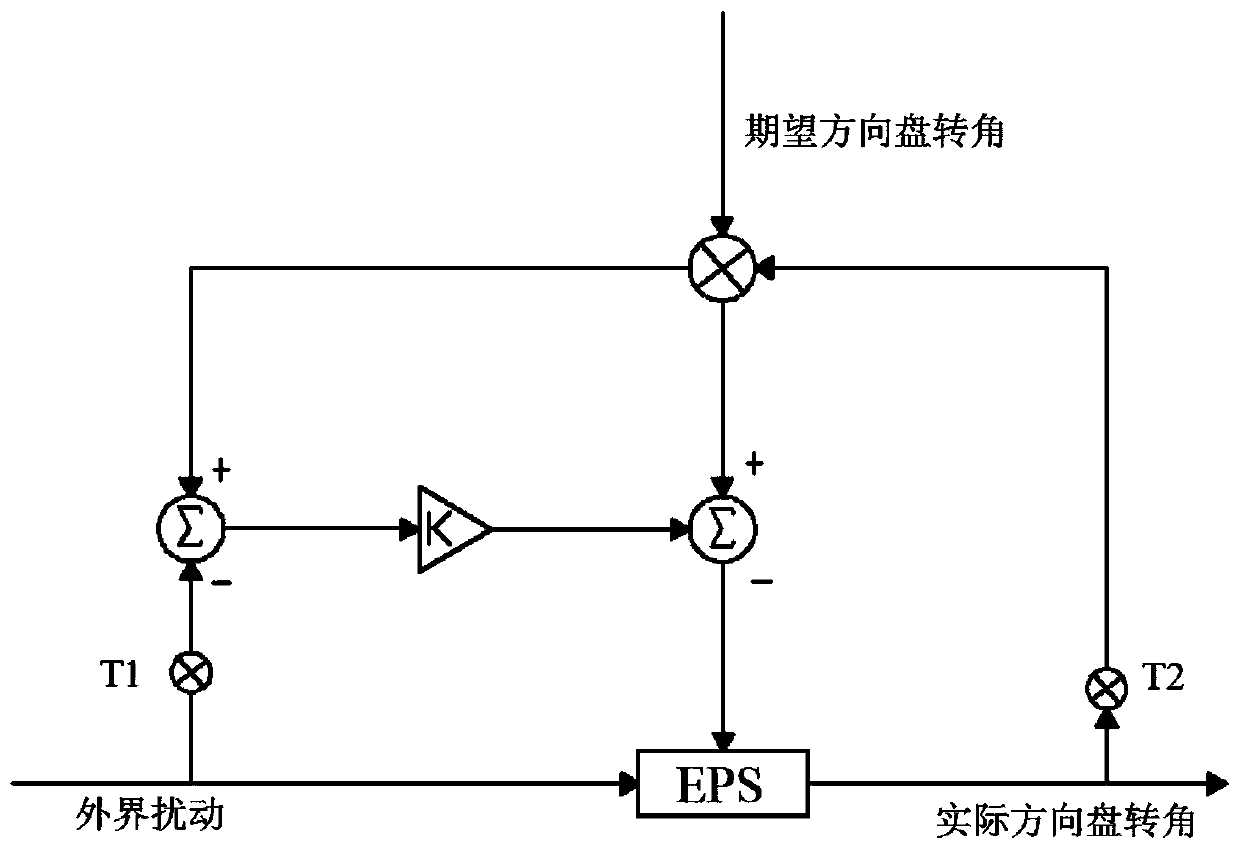

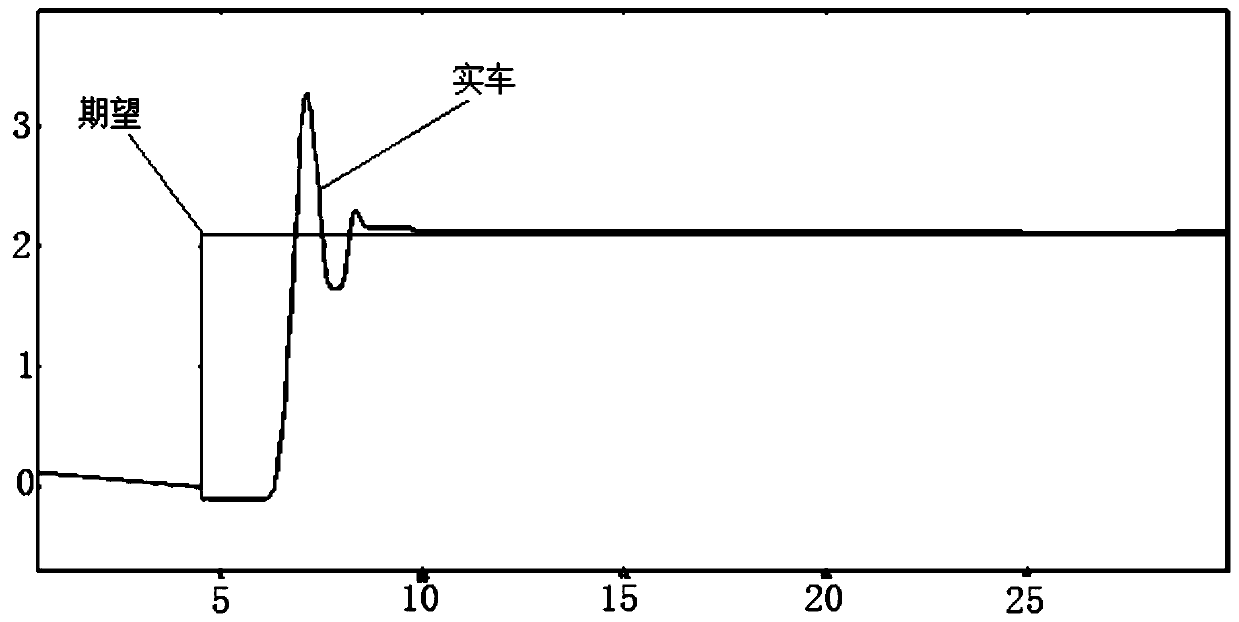

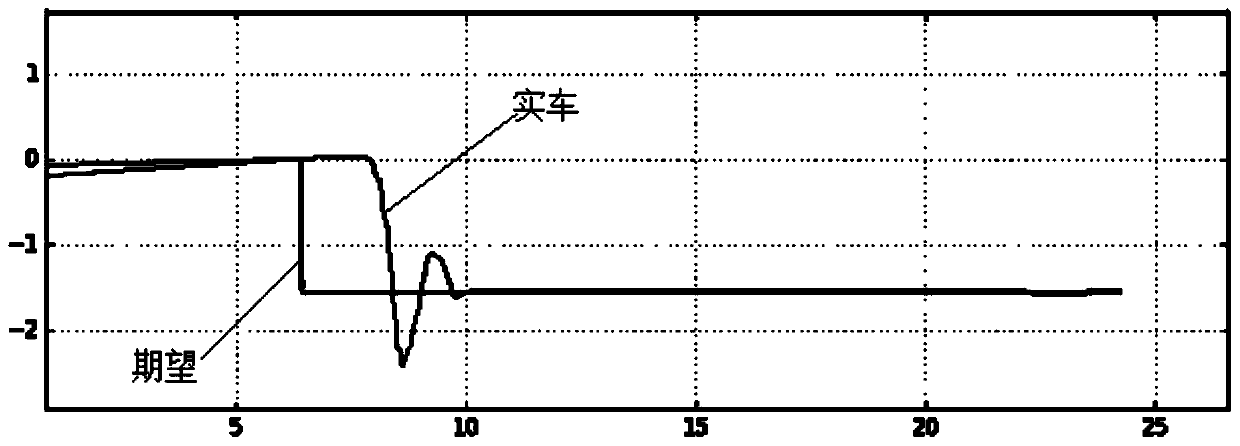

Intelligent driving vehicle transverse control method and control system

The invention discloses an intelligent driving vehicle transverse control method. The method comprises the steps of: establishing a transverse control feedforward control system model, a feedback control system model, a feedforward control torque calibration simulation model and a feedback control torque calibration simulation model; performing first parameter adjustment on the feedforward controltorque calibration simulation model and the feedback control torque calibration simulation model; performing real vehicle verification on feedforward control and feedback control torque calibration simulation model parameters obtained by first parameter adjustment; changing different expected working conditions to repeatedly execute the verification steps, calibrating parameters of the feedforward control and feedback control torque calibration simulation model under different expected working conditions, and obtaining optimal parameters of the feedforward control and feedback control torquecalibration simulation model; and performing parameter optimization on the feedforward control torque calibration simulation model and the feedback control torque calibration simulation model by usingthe optimal parameters, and performing simulation debugging on the remaining uncalibrated parameters to obtain all calibration parameters. The invention further discloses an intelligent driving vehicle transverse control system.

Owner:LIANCHUANG AUTOMOBILE ELECTRONICS

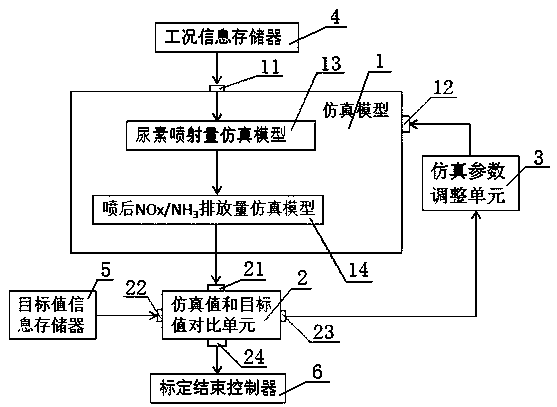

Urea-SCR control parameter off-line calibration system and calibration method

PendingCN109411027AReduce test contentShorten the calibration cycleChemical processes analysis/designInternal combustion piston enginesInequationEngineering

The invension provides a Urea-SCR control parameter off-line calibration system, which comprises a simulation model, a simulation value and target value comparison unit and a simulation parameter adjustment unit. When running, the simulation model firstly calculates and obtains a urea injection amount simulation value or a post-injection NOx / NH3 emission simulation value according to the working condition information stored in a working condition information memorizer and transmits the urea injection amount simulation value or the post-injection NOx / NH3 emission simulation value to a simulation value and target value comparison unit, then the simulation value and target value comparison unit compares the received simulation value with the target value, if the inequation |the simulation value- the target value| > e is satisfied, the simulation parameter adjustment unit adjusts the simulation parameter and then inputs the adjusted simulation parameter into the simulation model to carry out the simulation calculation of the next round, if the inequation |the simulation value- the target value| < e is satisfied, the calibration is finished, wherein e refers to a maximum allowable deviation value. The design not only shortens the calibration period and saves the calibration cost, but also remarkably reduces the calibration working strength.

Owner:DONGFENG COMML VEHICLE CO LTD

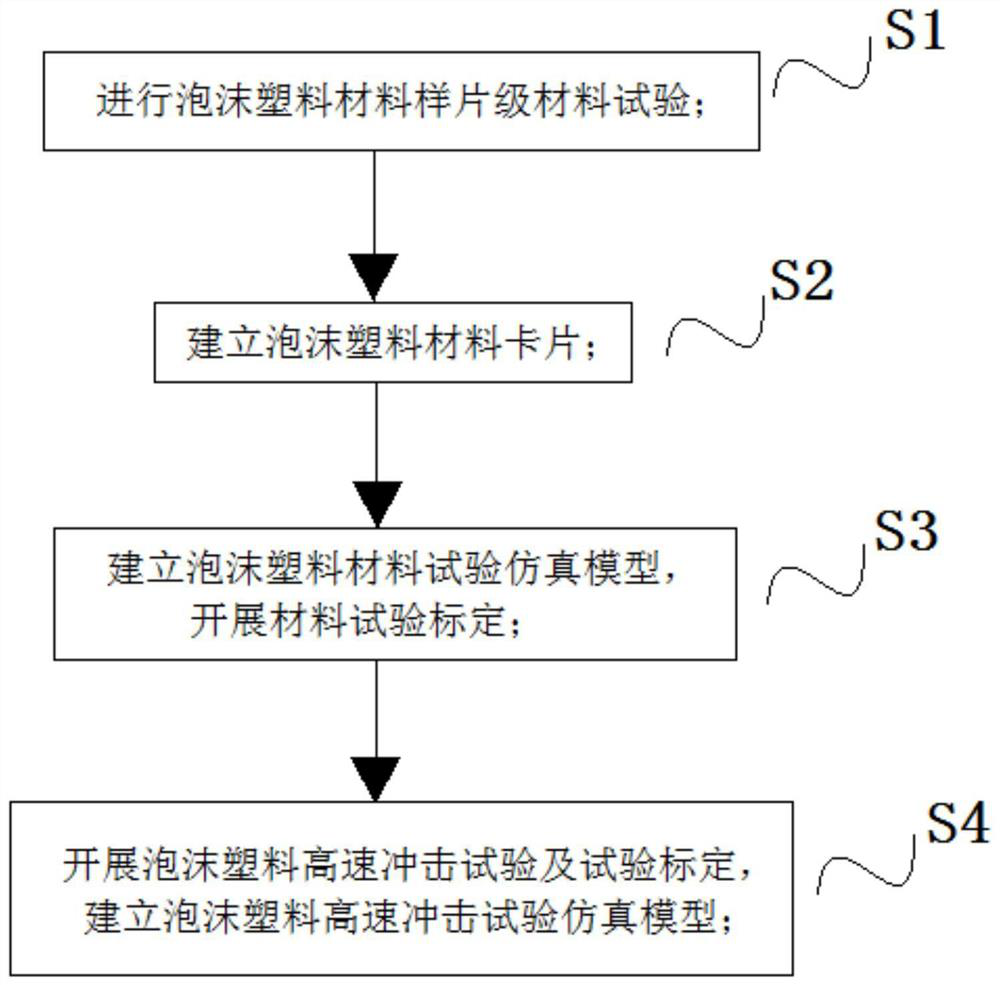

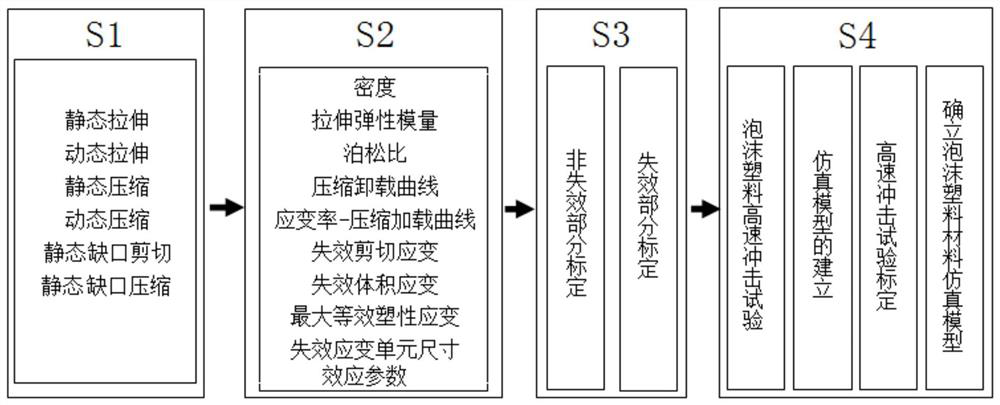

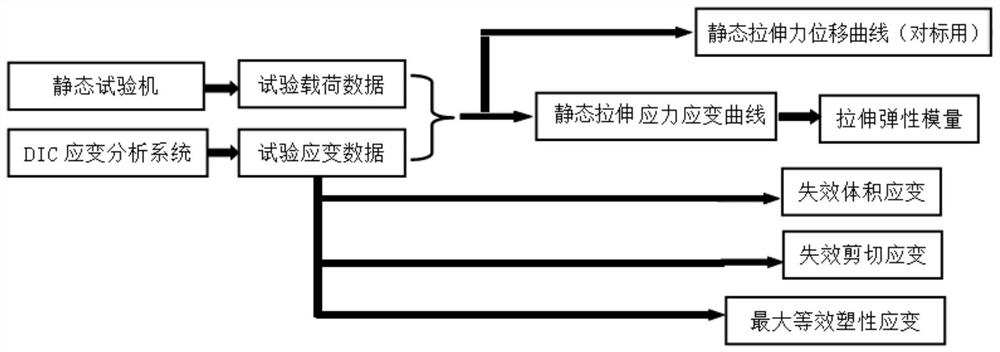

Collision analogue simulation method for automobile foamed plastic material

ActiveCN111753373AReduce the difficulty of calibrationShorten the calibration cycleGeometric CADDesign optimisation/simulationFinite element analysis softwarePlastic materials

The invention discloses a collision analogue simulation method for an automobile foamed plastic material. The method comprises the following steps: carrying out a foamed plastic material sample-levelmaterial test to obtain material data including test force-displacement curves under different test force states and the failure strain of the material under different stress states; establishing an MAT*_083 material card and an MAT*_ADD_EROSION material card of the foamed plastic by applying LS-DYNA finite element analysis software in combination with the material data obtained in the step S1, and determining parameters required to be calibrated by the material cards; establishing a material test simulation model, and carrying out material test calibration including a non-failure part and a failure part; carrying out a foamed plastic high-speed impact test, substituting the calibrated material card into the foamed plastic high-speed impact simulation model, and determining a final foamedplastic high-speed impact test simulation model through foamed plastic test calibration. According to the invention, the accurate analogue simulation of deformation and fracture failure characteristics of an automobile foamed plastic material can be realized.

Owner:CHINA FIRST AUTOMOBILE

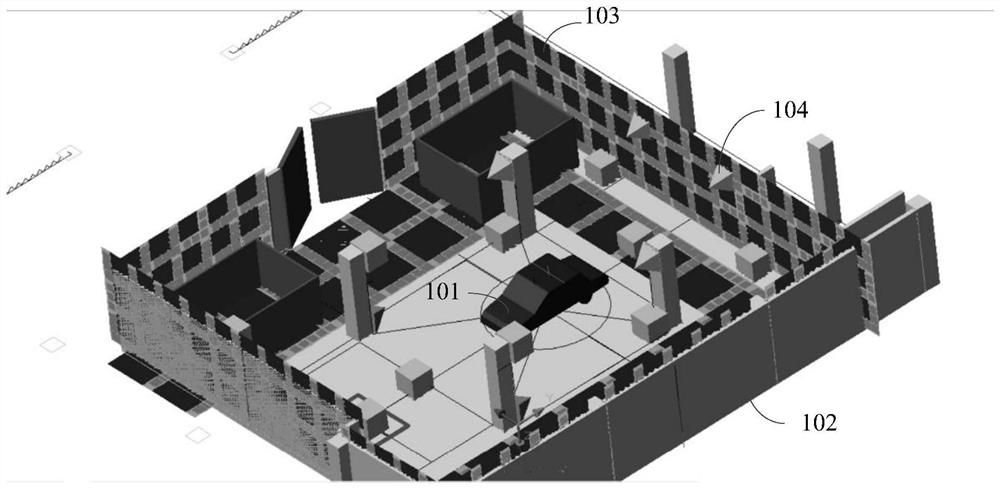

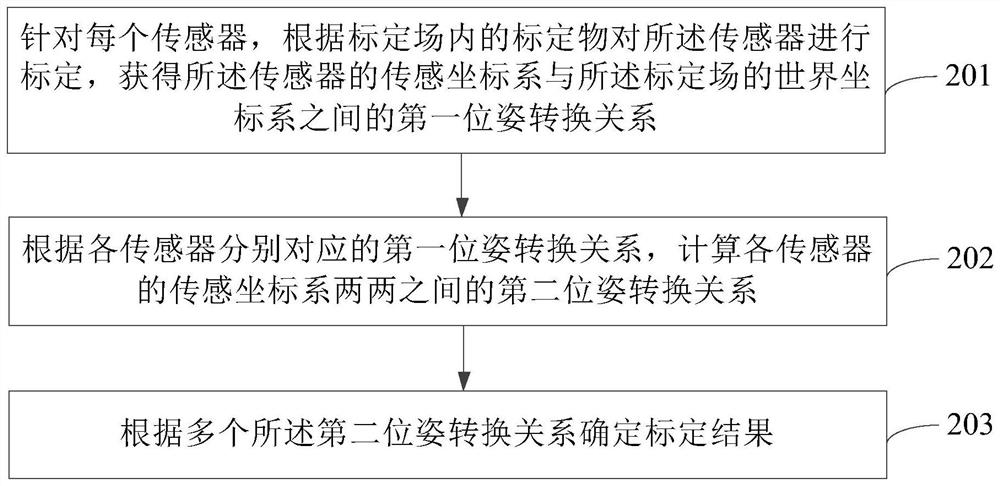

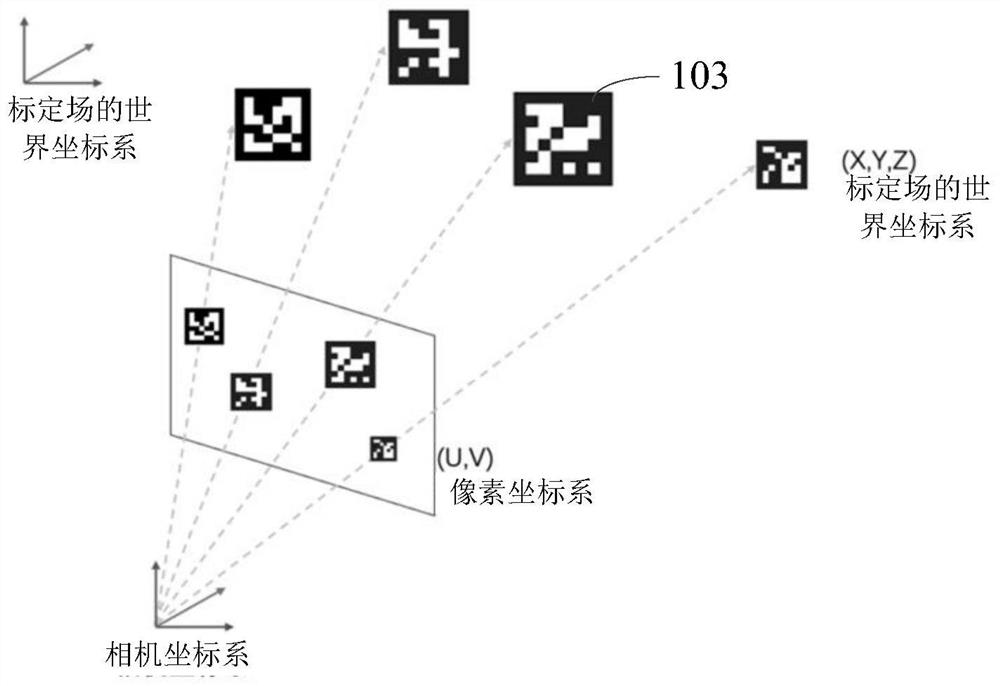

Multi-sensor joint calibration method and device, storage medium and program product

PendingCN114578329AShorten the calibration cycleImprove calibration efficiencyImage analysisWave based measurement systemsEngineeringCalibration result

The embodiment of the invention provides a multi-sensor joint calibration method and device, a storage medium and a program product, and the method comprises the steps: calibrating each sensor according to a calibration object in a calibration field, obtaining a first pose conversion relation between a sensing coordinate system of the sensor and a world coordinate system of the calibration field, according to the first pose conversion relations corresponding to the sensors, second pose conversion relations between every two sensing coordinate systems of the sensors are calculated, and a calibration result is determined according to the multiple second pose conversion relations. According to the embodiment of the invention, each sensor is calibrated through the calibration object in the calibration field, the conversion relation between the sensor coordinate of each sensor and the world coordinate system of the calibration field is obtained, the conversion relation between every two sensors can be rapidly obtained on the basis, the whole vehicle calibration is completed, and the calibration efficiency is improved. The calibration period of whole vehicle calibration can be greatly shortened, and the calibration efficiency is improved.

Owner:ECARX (HUBEI) TECHCO LTD

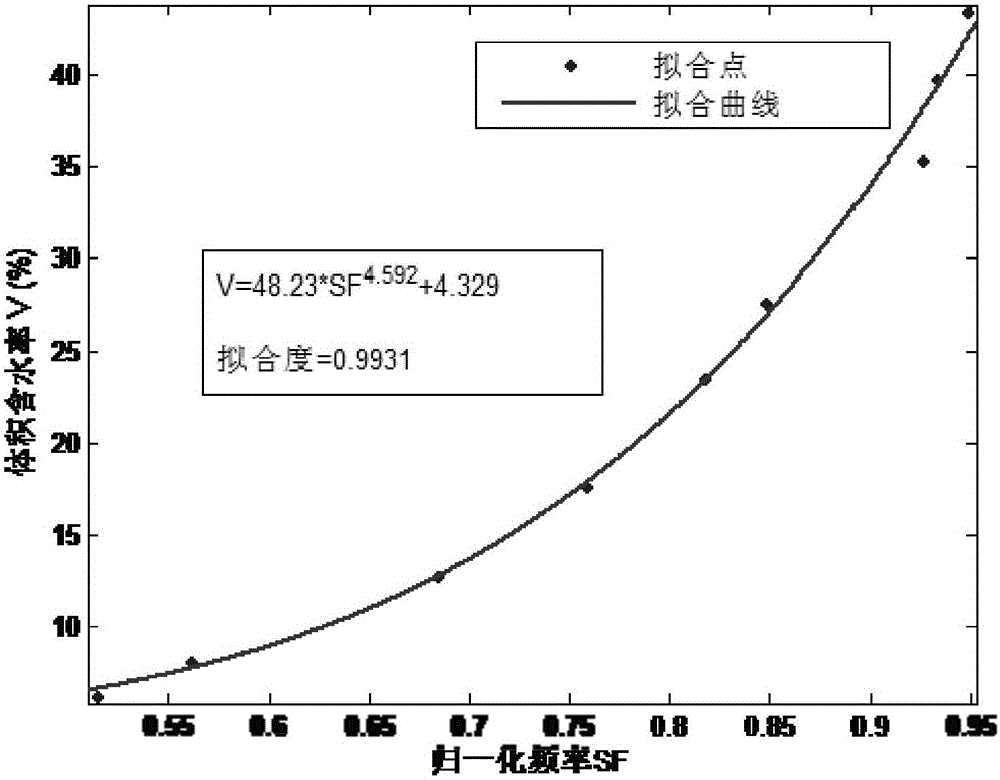

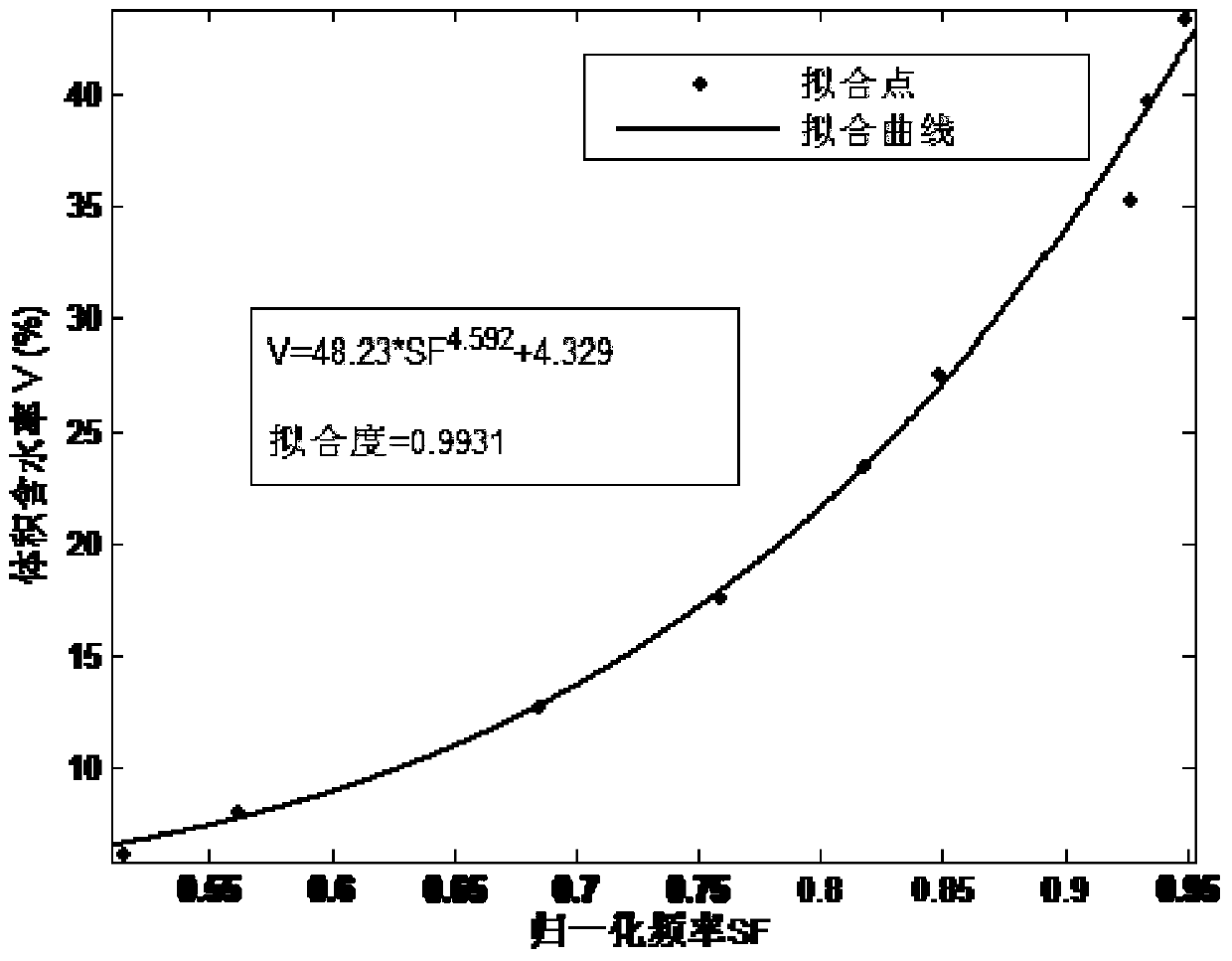

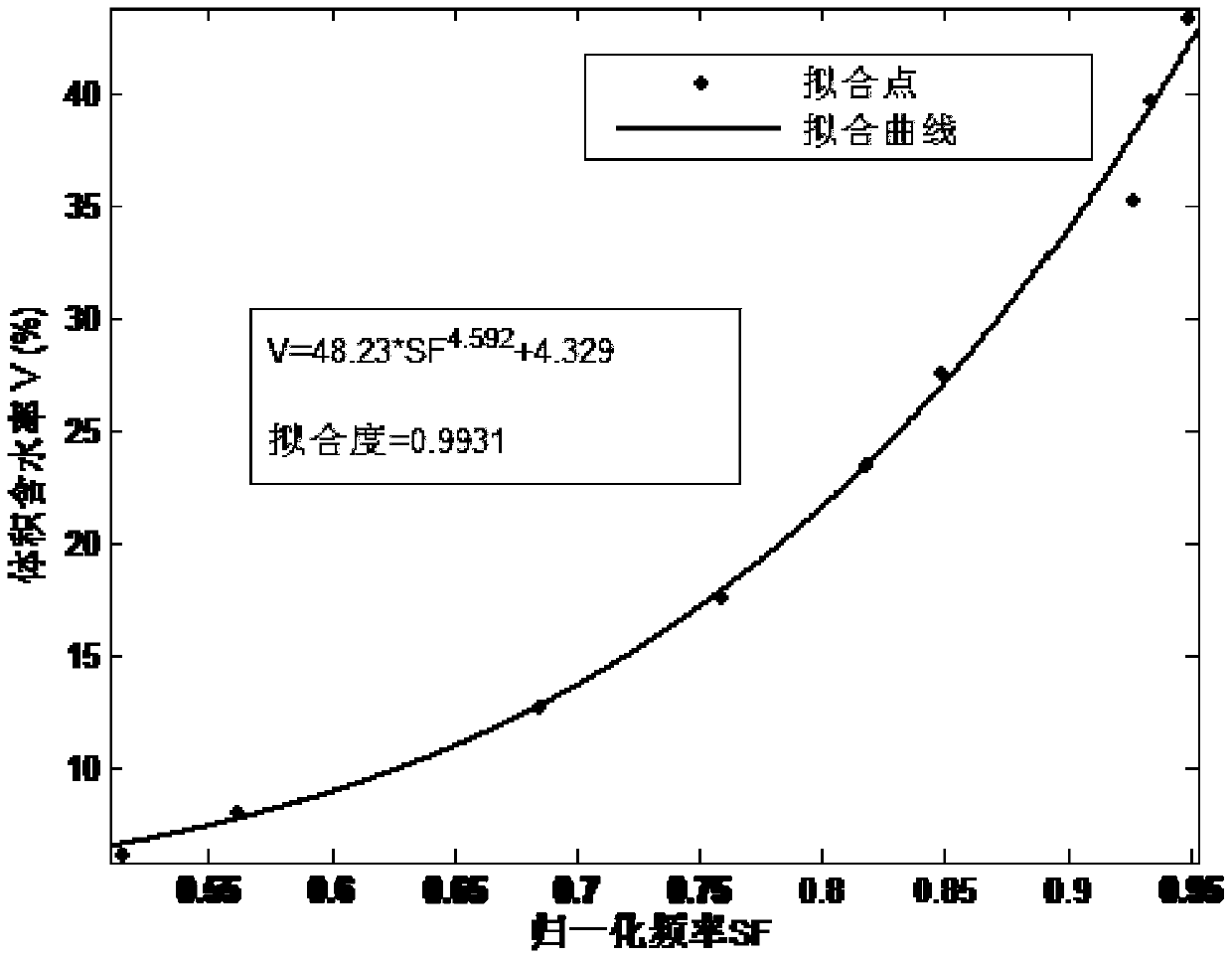

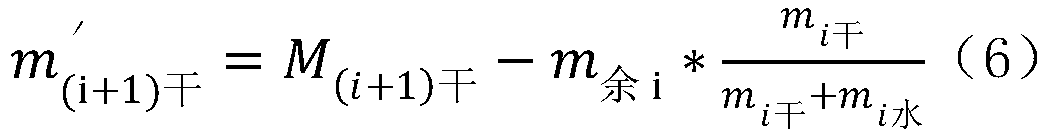

Laboratory calibration method for soil moisture sensors

InactiveCN106248522AHigh precisionShorten the calibration cycleWeighing by removing componentEarth material testingPhysicsSoil moisture sensor

The invention discloses a laboratory calibration method for soil moisture sensors. After the volume weights and volume moisture contents of fitting point soil samples and verifying point soil samples are set, the soil samples are evenly mixed with water, next soil samples are made by recycling the made soil samples, the original measured frequency values of the soil moisture sensors are recorded in sequence at the same time, data is fit with Matlab software, and a calibration equation is obtained finally. By means of the calibration method, the calibration period can be shortened, and the workload can be reduced; besides, data output by the calibrated sensors finally is high in precision and small in error.

Owner:XIAN SITAN ENVIRONMENT TECH CO LTD

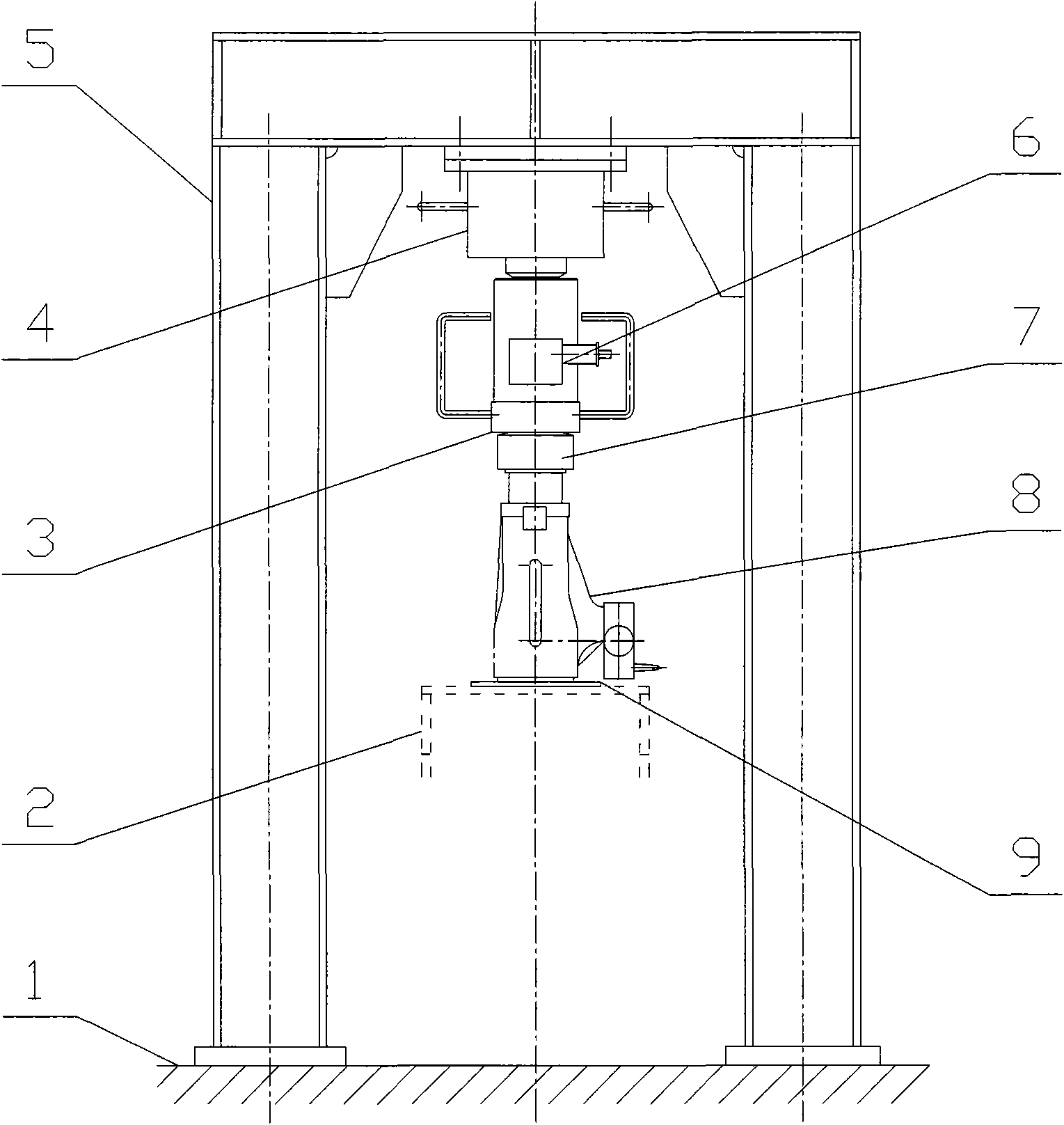

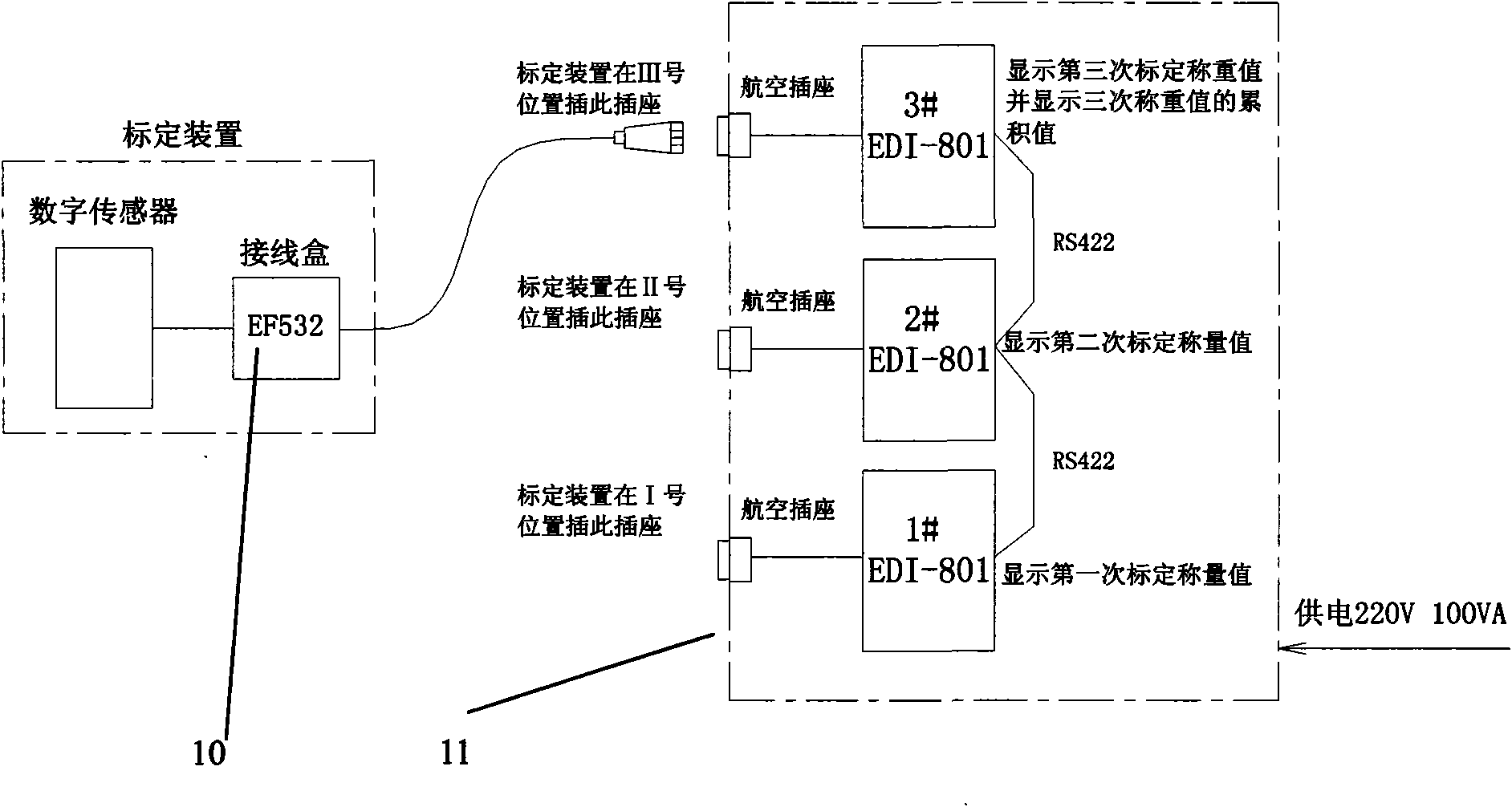

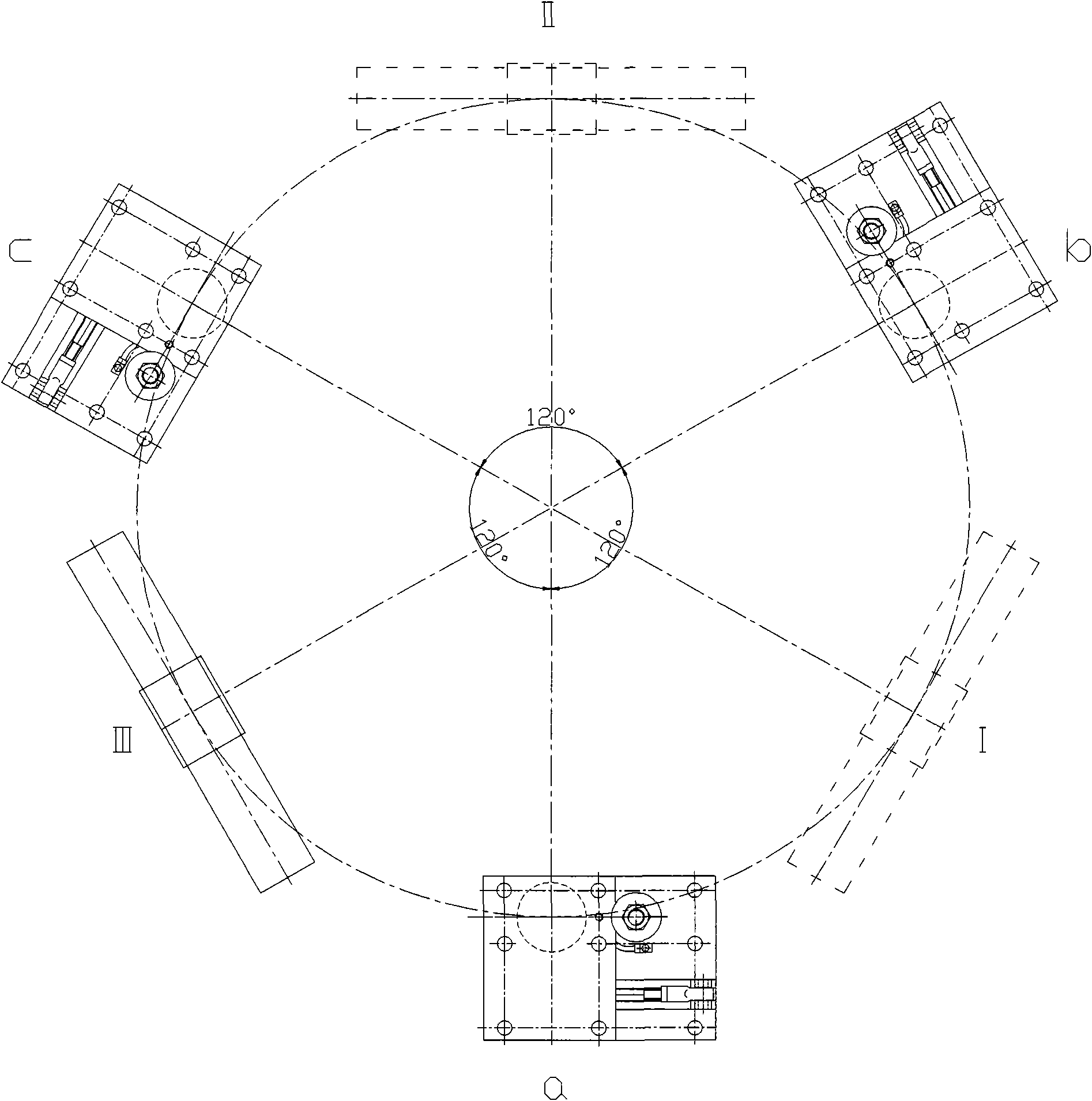

Hopper scale calibration device based on digital sensor

ActiveCN101598593ASimple structureReduce manufacturing costWeighing apparatus testing/calibrationMaterial resourcesEngineering

The invention relates to the technical field of a measurement detection device, in particular to a hopper scale calibration device based on a digital sensor, comprising a frame of which the lower end can be connected with a hopper scale tressel, wherein a bumper is arranged on the frame, a digital type weighing sensor is arranged below the bumper, the lower end of the digital type weighing sensor is connected with the upper end of a lifting jack by a connecting piece, and the lower end of the lifting jack can be connected with a hopper bracket. The invention mainly solves the defect of the hopper scale calibration device of the existing analog sensor, also has the advantages of simple structure and low manufacture and use cost, shortens the calibration time and period when being used, simplifies the calibration mode, saves large numbers of manpower and material resources and has wide use value and popularization prospect.

Owner:SHANGHAI YAMATO SCALE

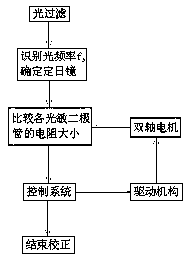

Offset correction system and correction method for tower-type heliostat

ActiveCN105509346AShorten the calibration cycleSolar heating energySolar heat collector controllersHeliostatControl system

The invention discloses an offset correction system and an offset correction method for a tower-type heliostat. The offset correction system comprises a light filter device, a heliostat, an offset correction system body, a control system and a drive mechanism, wherein the light filter device is positioned on the surface of the heliostat; the offset correction system is used for sending offset of the heliostat to the control system; the control system is used for controlling motion of the drive mechanism; and the drive mechanism is used for driving the heliostat to move according to an instruction output by the control system. The offset correction system solves the technical problems that a current tower-type heliostat is long in check cycle and is poor in timeliness of check results. By applying the offset correction method for the tower-type heliostat, offset correction can be simultaneously carried out on a plurality of heliostats without mutual influence, so that the check cycle is shortened.

Owner:北京绿贝区块链科技有限公司

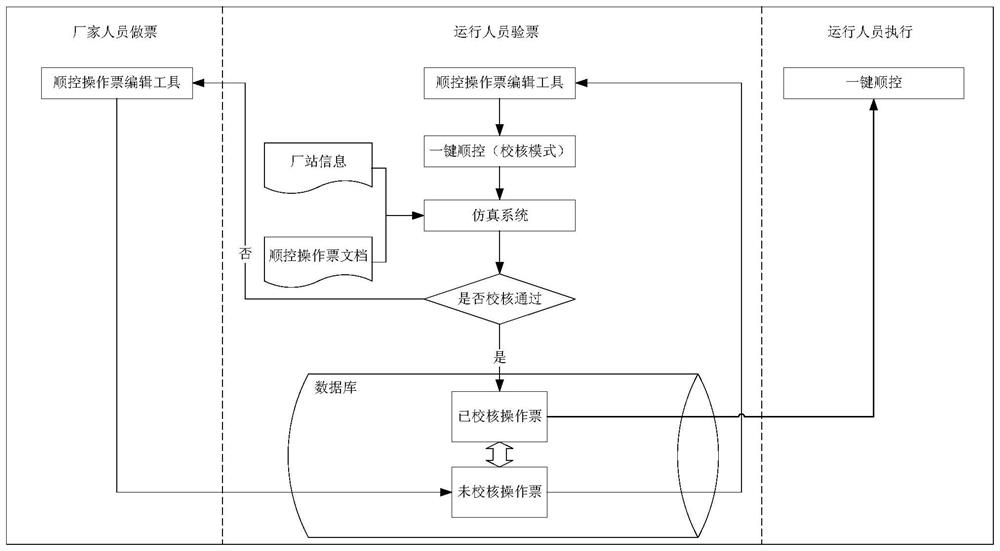

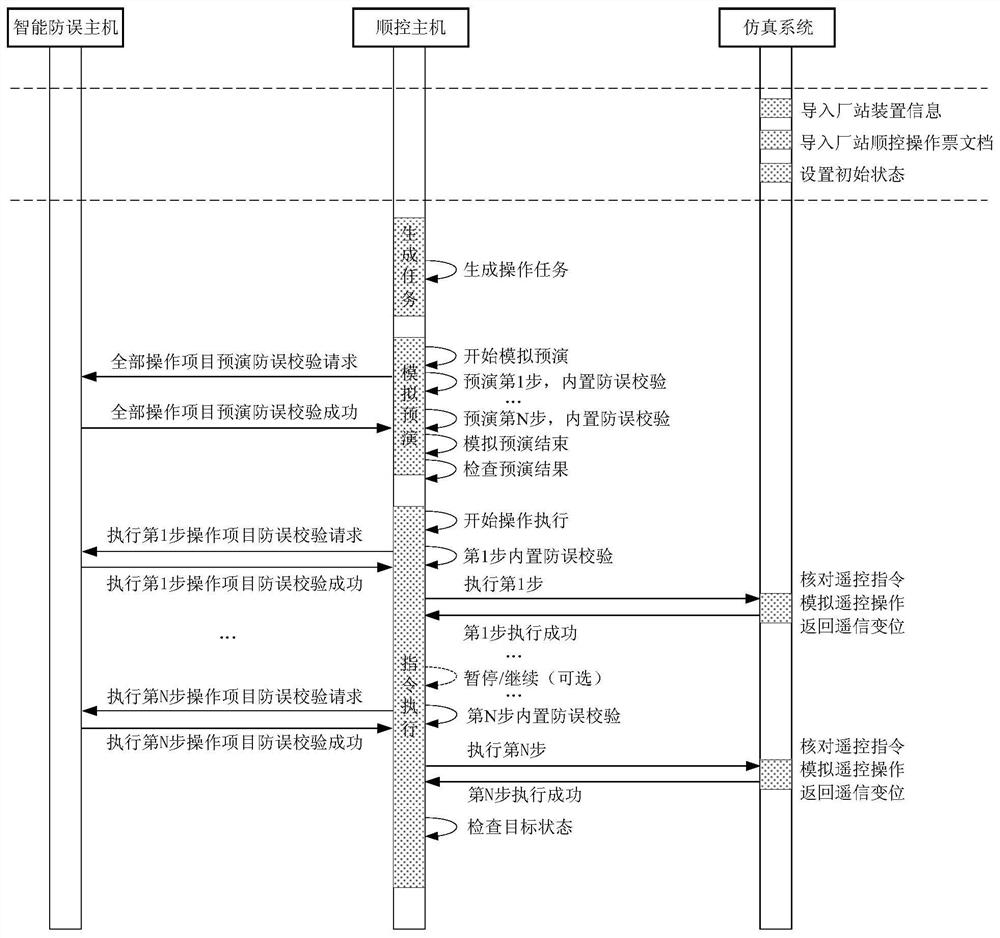

Sequential control operation ticket non-power-off checking method and system

ActiveCN112186739AOvercoming the defects of partial blackouts in turnsSolution conditionsSystems intergating technologiesInformation technology support systemTransformerControl engineering

The invention discloses a sequential control operation ticket non-power-failure checking method and system, which simulate a plant station, replace actual physical devices to communicate with a sequence control host, overcome the defect that partial power failure needs to be performed in turns in an existing sequence control operation ticket checking scheme, are completely consistent with a one-key sequence control actual operation process, are convenient and fast to implement, and improve the checking efficiency. The problems that a traditional checking mode does not have power failure ticketchecking conditions and is too long in checking period are solved, the checking period of sequential control operation tickets is shortened, the operation and maintenance work efficiency of a transformer substation is improved, one-key sequential control technology application is deepened, and safe and efficient operation of a power grid is guaranteed.

Owner:NR ELECTRIC CO LTD +1

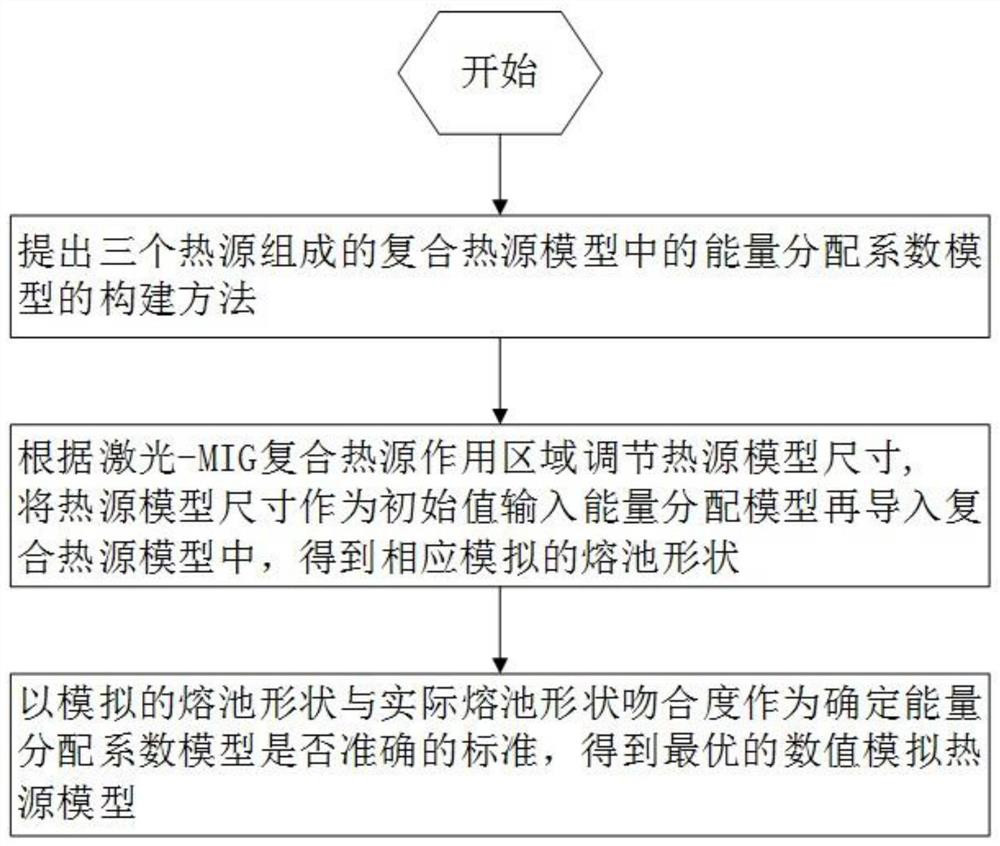

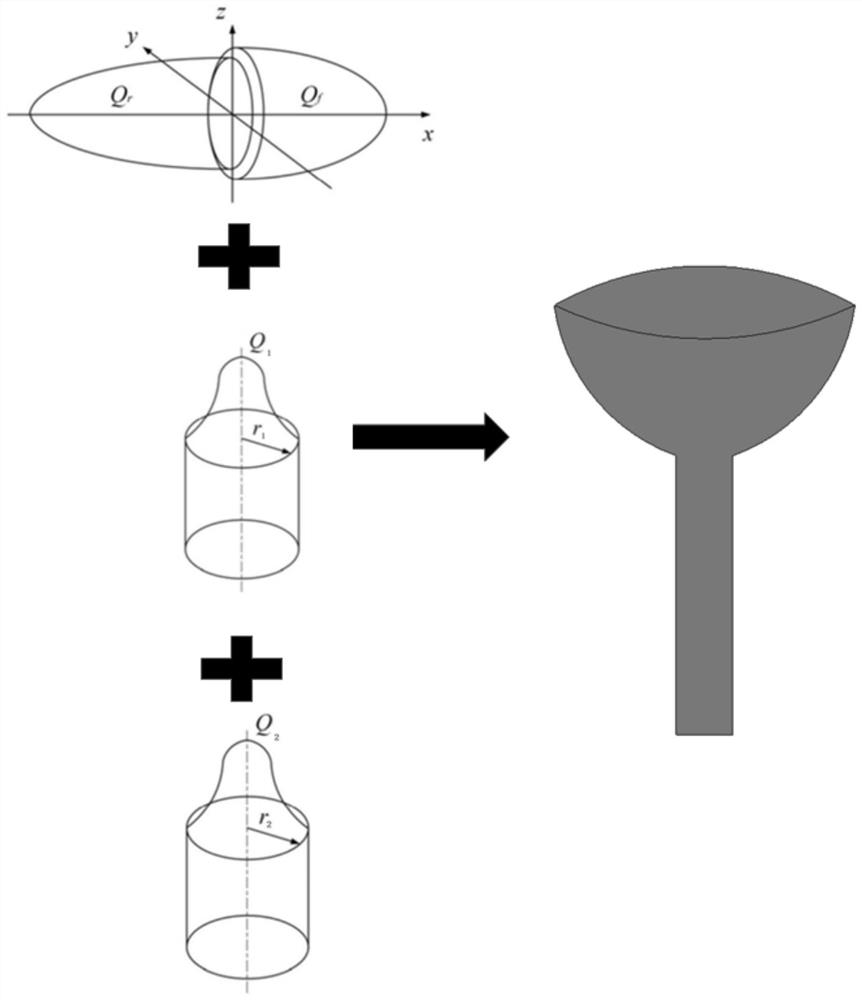

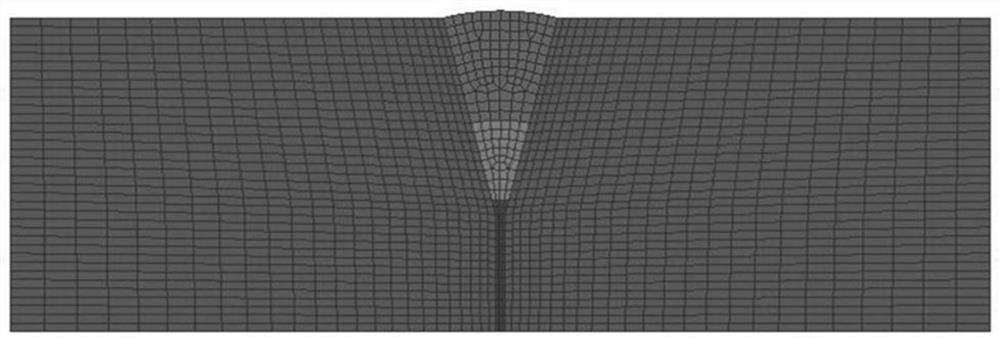

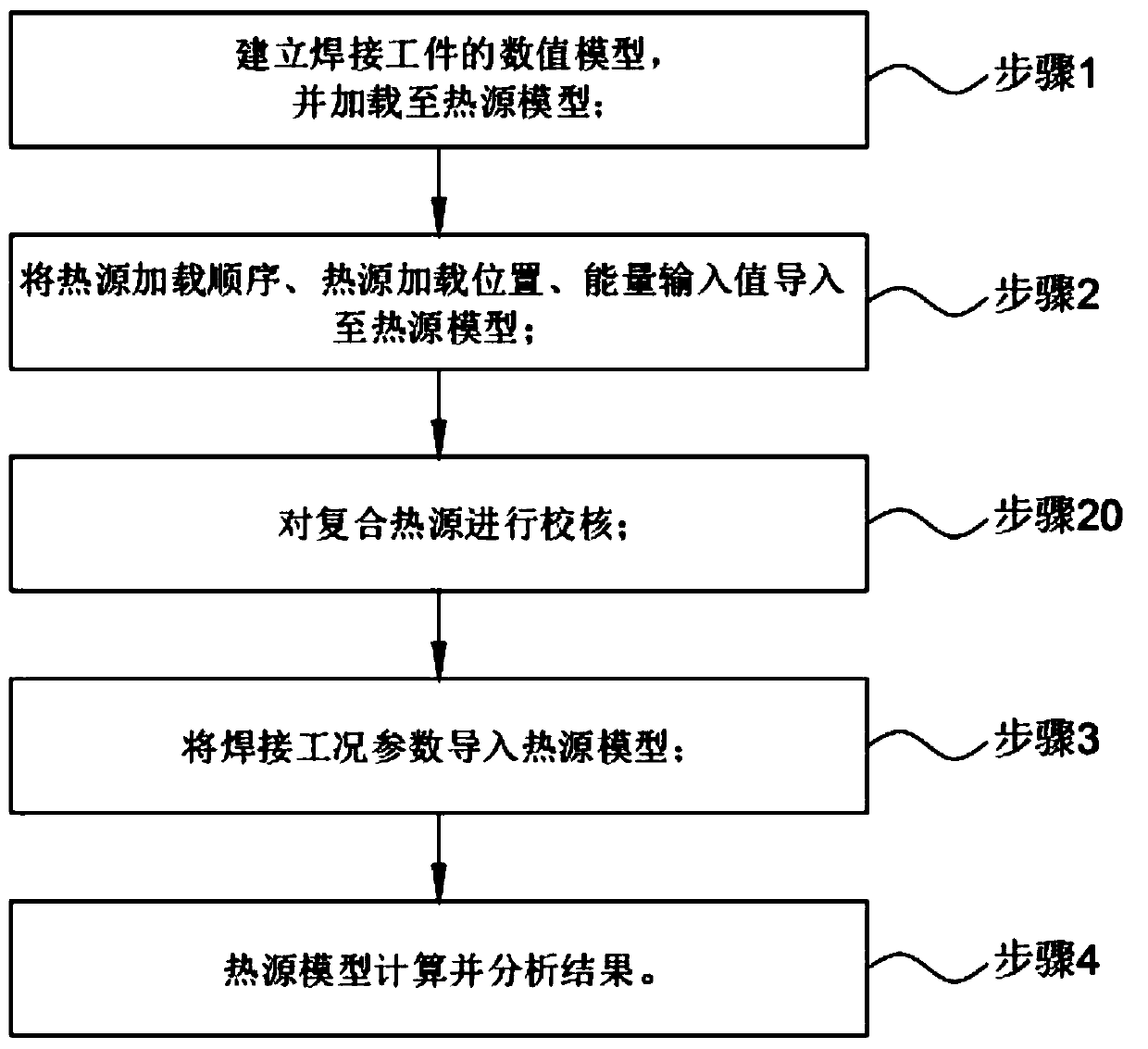

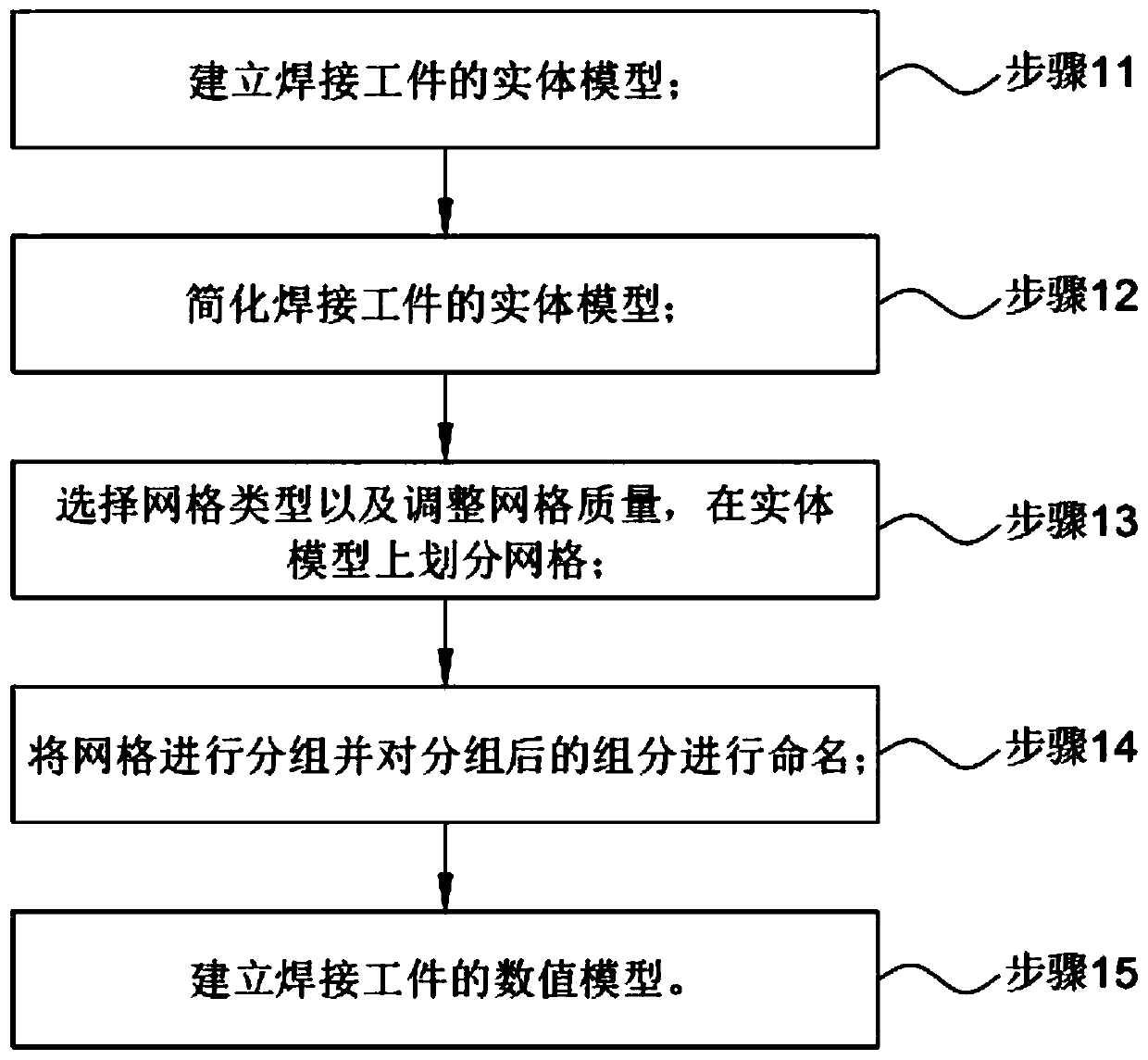

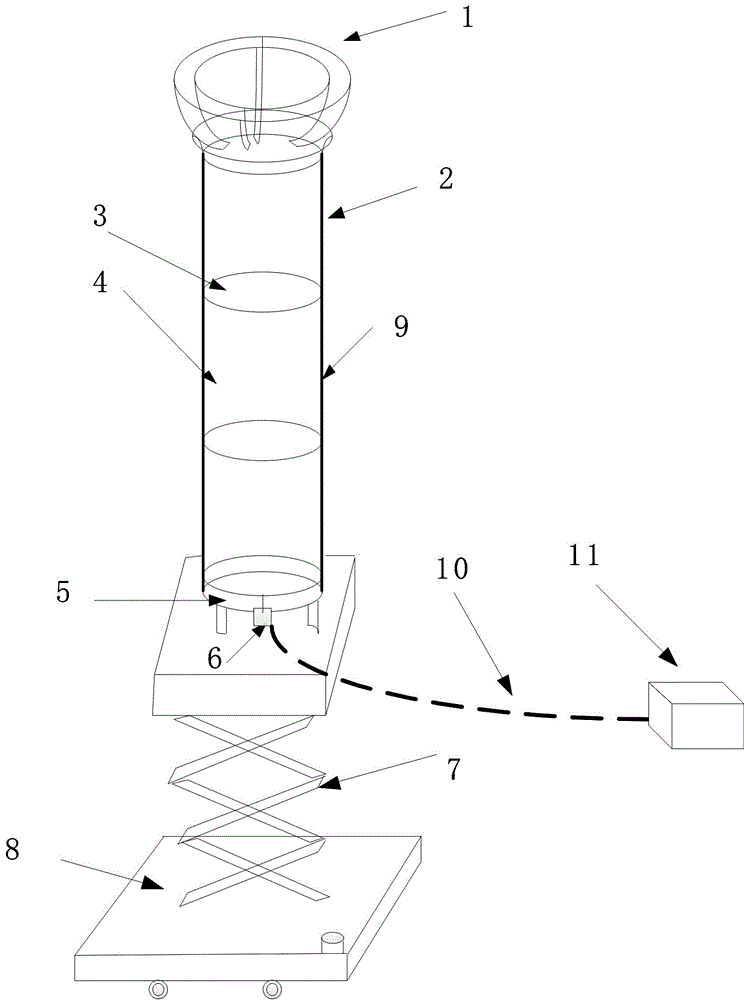

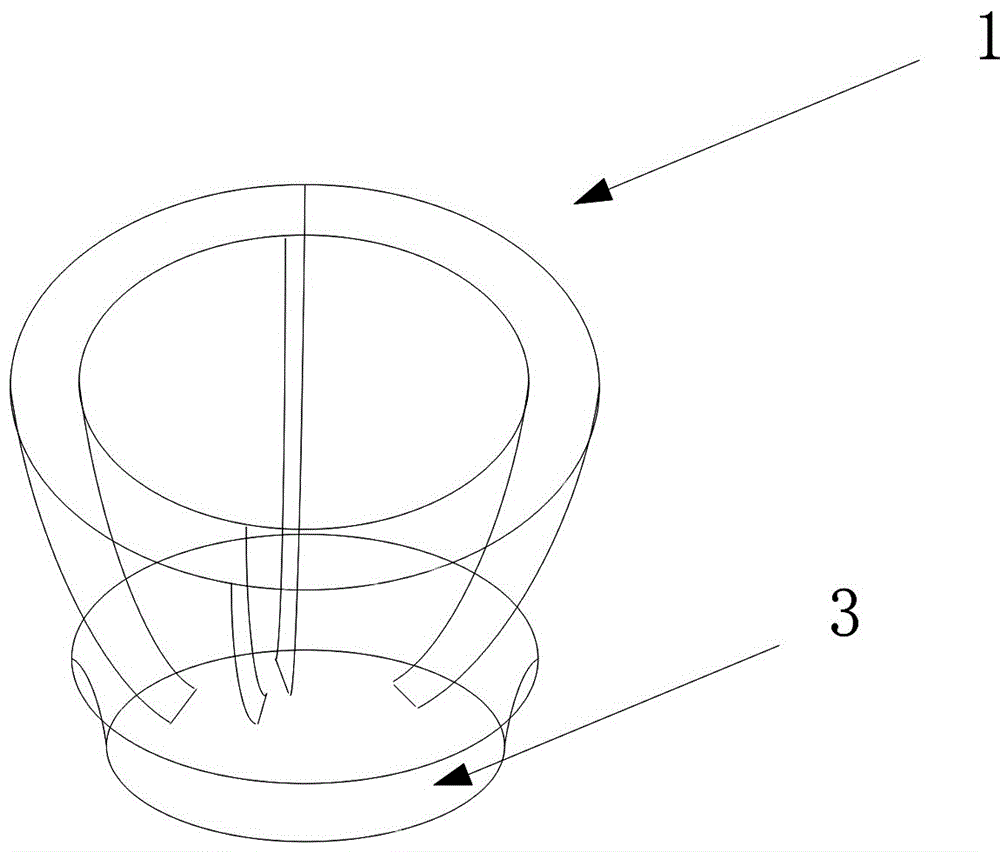

Modeling method of laser arc composite heat source based on energy distribution coefficient

ActiveCN111695256AShorten the calibration cycleShort timeDesign optimisation/simulationSpecial data processing applicationsThermodynamicsProcess engineering

The invention discloses a modeling method of a laser arc composite heat source based on an energy distribution coefficient in the technical field of laser welding, and aims at solving the technical problems that in the prior art, the heat source checking period is long during welding simulation, and the shape goodness of fit of a simulated molten pool and an actual molten pool is not high. The method comprises the steps of acquiring the parameters of an actual molten pool; constructing a laser arc composite heat source model based on a pre-constructed energy distribution coefficient model between any two component heat sources, acquiring the parameters of a simulated molten pool based on the laser arc composite heat source model; and comparing the parameters of the simulated molten pool with the parameters of the actual molten pool to obtain the goodness of fit of the simulated molten pool relative to the actual molten pool, judging whether the goodness of fit reaches a preset threshold value or not, adjusting the heat source parameters, and taking the laser arc composite heat source model when the goodness of fit reaches the preset threshold value as a final model of the laser arccomposite heat source.

Owner:HOHAI UNIV CHANGZHOU

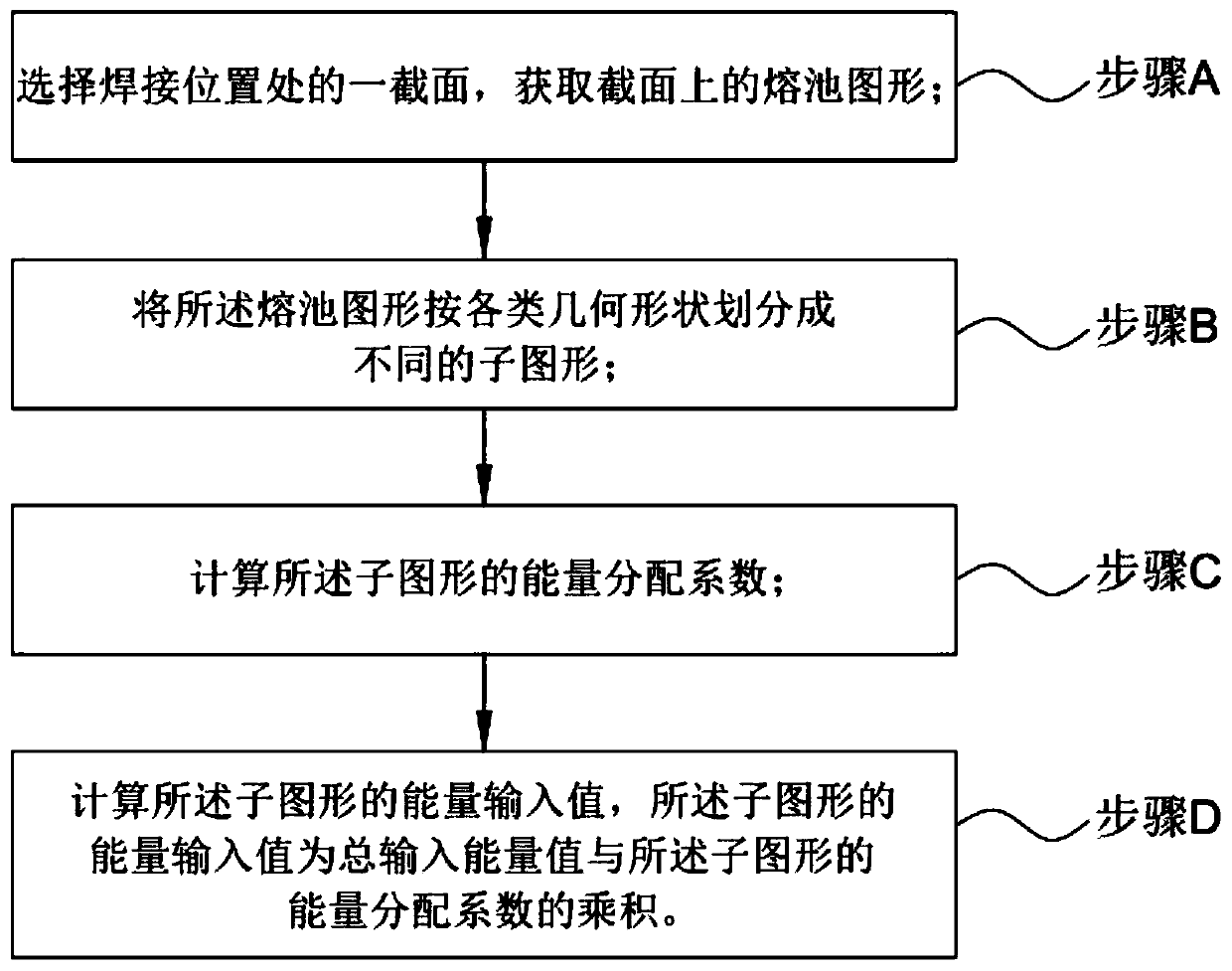

A method for determining energy distribution of a composite heat source and a welding simulation method

ActiveCN109885946AShorten the calibration cycleShort timeSpecial data processing applicationsEnergy partitioningEnergy distribution

The invention relates to the field of welding machining, in particular to a method for determining energy distribution of a composite heat source and a welding simulation method. The method for determining the energy distribution of the composite heat source comprises the steps that selecting a section at a welding position, and obtaining a molten pool graph on the section; dividing the molten pool graph into different sub graphs according to various geometrical shapes; calculating an energy distribution coefficient of the sub-graph; and calculating an energy input value of each sub-graph. Theenergy input value is close to the actual energy input quantity; when heat source checking is carried out, using the energy input value as an initial value to be imported into a heat source model. Compared with a molten pool graph obtained through numerical calculation and a molten pool graph of an actual workpiece, basic matching can be achieved only through fine adjustment of relevant heat source parameters such as an energy input value, complex repeated adjustment is not needed, the checking period of the composite heat source is greatly shortened, and then the time consumption of the whole welding simulation is shortened.

Owner:HANS LASER TECH IND GRP CO LTD +1

Voltage sensor suitable for field measurement of transformer substation

PendingCN106842098ARealize verificationReduce volumeElectrical measurementsCapacitanceParallel plate

A voltage sensor suitable for field measurement of a transformer substation comprises a grading ring, a primary voltage sensing unit, an acquisition transmission unit and an elevating platform. According to the voltage sensing unit, a high-voltage capacitor and a low-voltage capacitor are composed of parallel-board capacitors; and high-voltage capacitor and the low-voltage capacitor are filled with air, thereby forming a gas capacitor. The high-voltage capacitor is composed of three gas capacitors with polar distances of 1.5m. The low-voltage capacitor is composed of one gas capacitor with polar distance of 0.04m. The high-voltage capacitor and the low-voltage capacitor realize voltage shunting through serial connection. The acquisition transmission unit is arranged below the low-voltage capacitor. Furthermore the acquisition transmission unit is connected with the low-voltage capacitor through an optical fiber. The acquisition transmission unit is obtained through successively connecting a signal processing module, an A / D conversion module and an FPGA. A signal which is output from the acquisition transmission unit is transmitted to a subsequent processing terminal through the optical fiber. The voltage sensor has advantages of realizing live verification to an electronic voltage transformer, shortening verification period, simplifying operation step, preventing loss caused by power failure, and improving accuracy and reliability in online verification of the electronic voltage transformer.

Owner:国网甘肃省电力公司金昌供电公司 +3

A Laboratory Calibration Method for Soil Moisture Sensor

InactiveCN106248522BHigh precisionShorten the calibration cycleWeighing by removing componentEarth material testingSoil scienceSoil moisture sensor

The invention discloses a laboratory calibration method for soil moisture sensors. After the volume weights and volume moisture contents of fitting point soil samples and verifying point soil samples are set, the soil samples are evenly mixed with water, next soil samples are made by recycling the made soil samples, the original measured frequency values of the soil moisture sensors are recorded in sequence at the same time, data is fit with Matlab software, and a calibration equation is obtained finally. By means of the calibration method, the calibration period can be shortened, and the workload can be reduced; besides, data output by the calibrated sensors finally is high in precision and small in error.

Owner:XIAN SITAN ENVIRONMENT TECH CO LTD

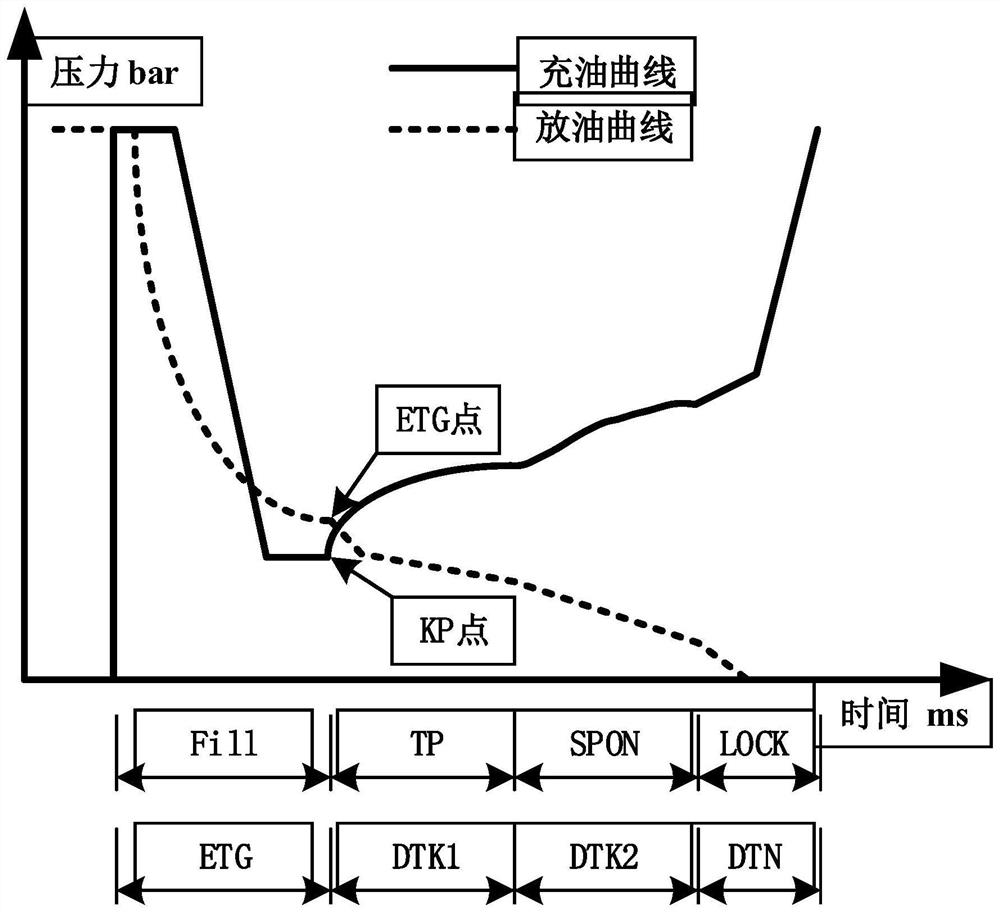

Automatic transmission calibration method

PendingCN114739658AImprove Calibration AccuracyImprove calibration efficiencyMachine gearing/transmission testingRoad transportAutomatic transmissionDriver/operator

The invention belongs to a transmission calibration method, and provides an automatic transmission calibration method in order to solve the technical problems that current automatic transmission calibration is long in period and high in cost, and the batch production efficiency of commercial vehicle automatic transmissions is seriously affected. A driver only needs to drive a vehicle, the pressure of a corresponding pressure point or the oil filling time is calibrated according to the appearing state and the inherent parameter point diagram of the automatic transmission in each stage of the gear shifting process, gear shifting is repeated, calibration optimization is continuously conducted till any segment does not have the related state any more in the gear shifting process, and the gear shifting process is completed. And calibration of the automatic transmission is completed. Through a self-learning calibration mode, the calibration of all gears can be quickly and automatically completed without depending on the experience of a calibration engineer, manual intervention is not needed, and the calibration efficiency is greatly improved while the calibration accuracy is improved.

Owner:SHAANXI FAST GEAR CO

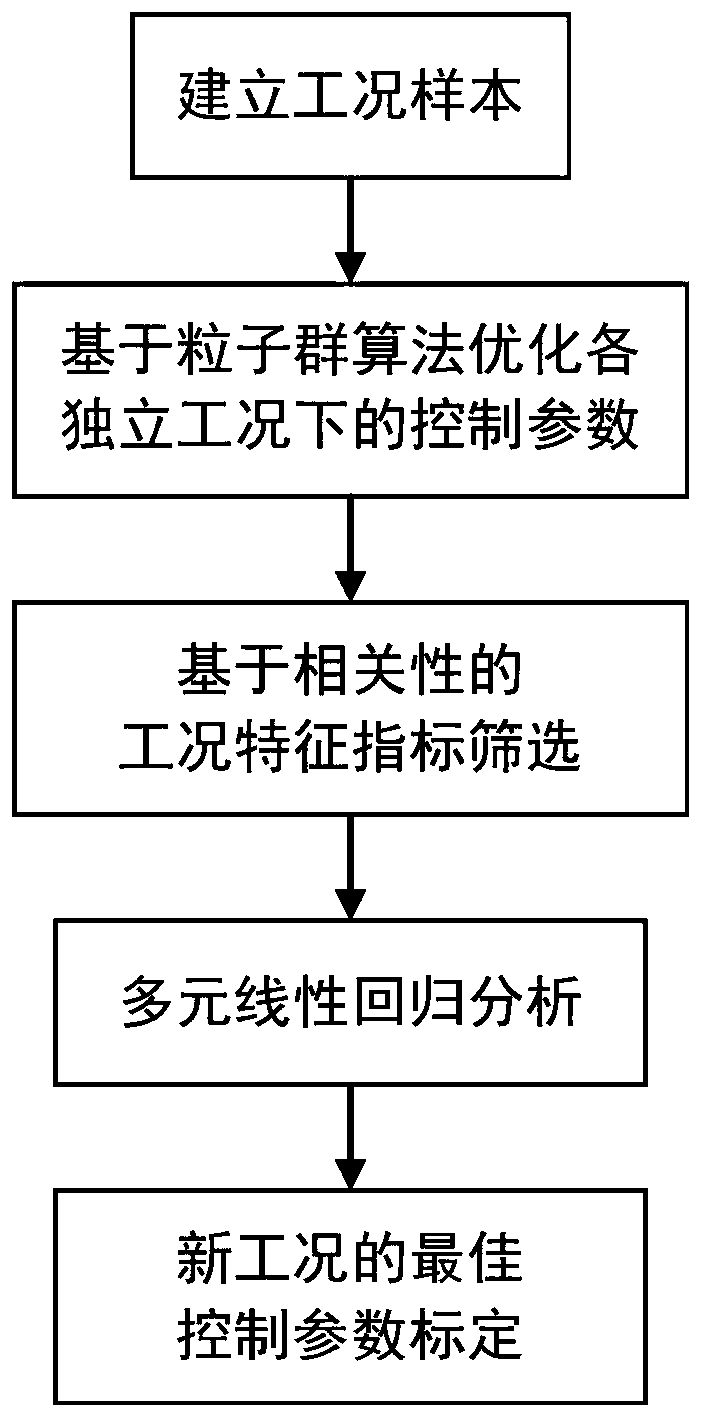

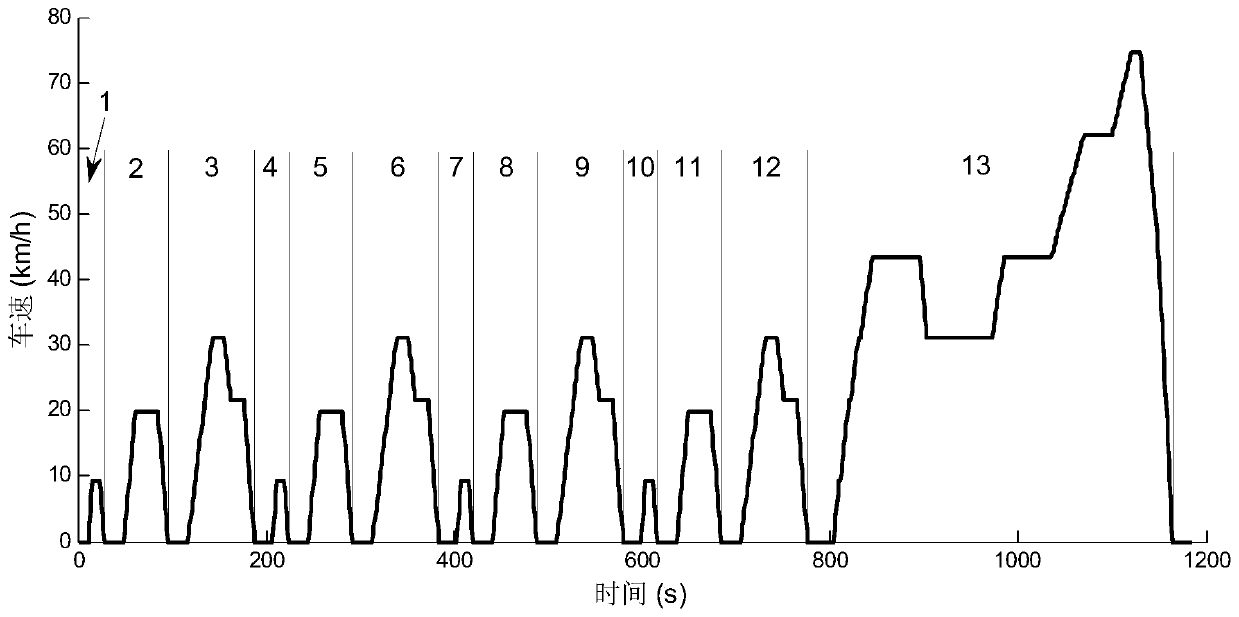

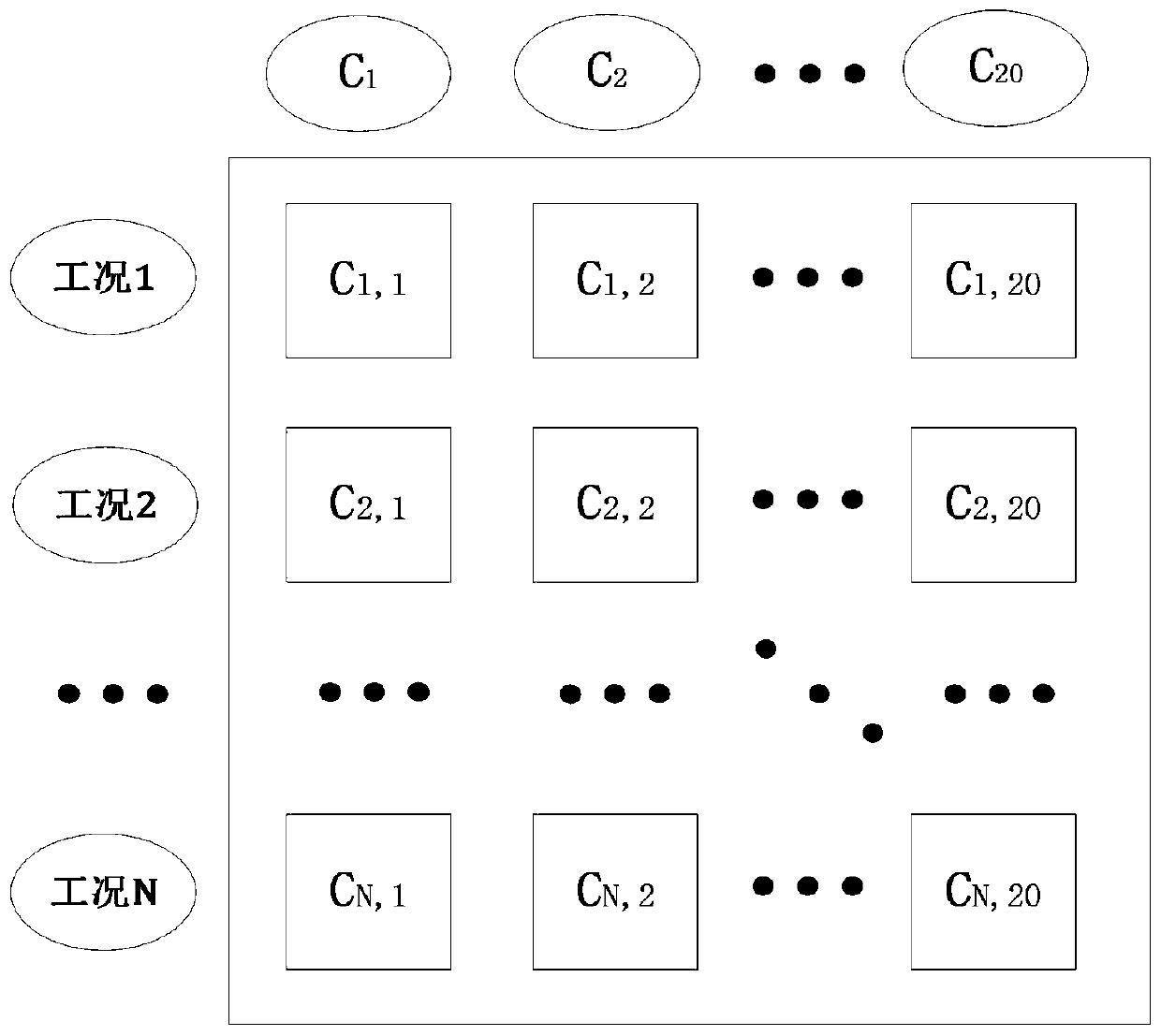

A working condition-oriented method for calibration of hybrid electric vehicle control parameters

ActiveCN109747654BQuick calibrationEasy to determineSpecial data processing applicationsMultiple linear regression analysisOptimal control

The invention discloses a working condition-oriented method for calibrating control parameters of a hybrid electric vehicle and relates to the technical field of hybrid electric vehicles. The method mainly includes the establishment of working condition samples, the optimization of control parameters under each independent working condition based on particle swarm optimization, the screening of working condition characteristic indicators based on correlation, multiple linear regression analysis, and the calibration of optimal control parameters for new working conditions. step. Fully consider the relationship between the working condition characteristics and the optimal control parameters, establish a multiple linear regression model between the optimal control parameters and the working condition characteristic indicators, and quickly calibrate the control parameters for different working conditions. On the one hand, it is helpful to understand The influence of working conditions on the optimal control parameters, on the one hand, facilitates the calibration personnel to quickly determine the optimal control parameters and shorten the calibration cycle.

Owner:JILIN UNIV

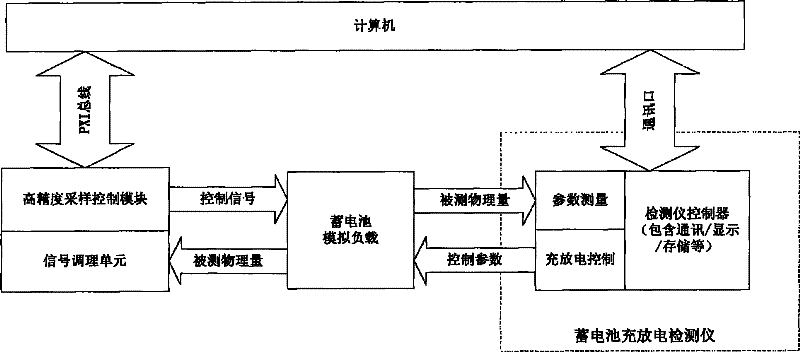

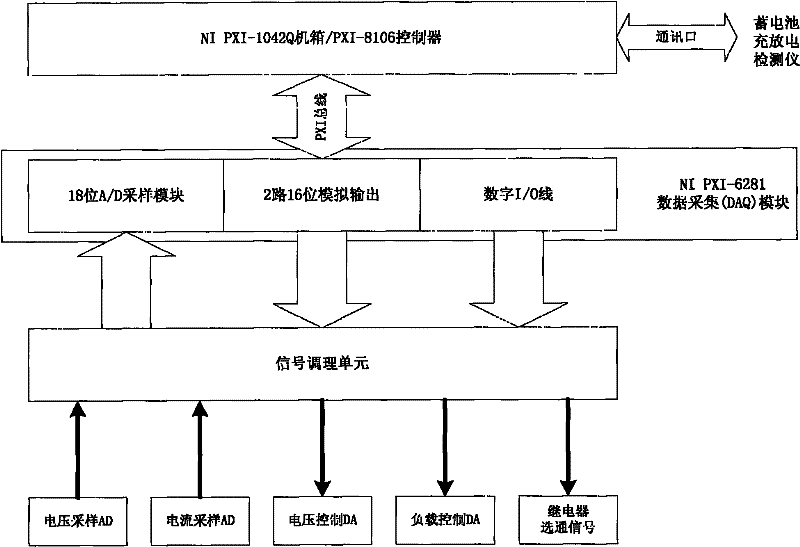

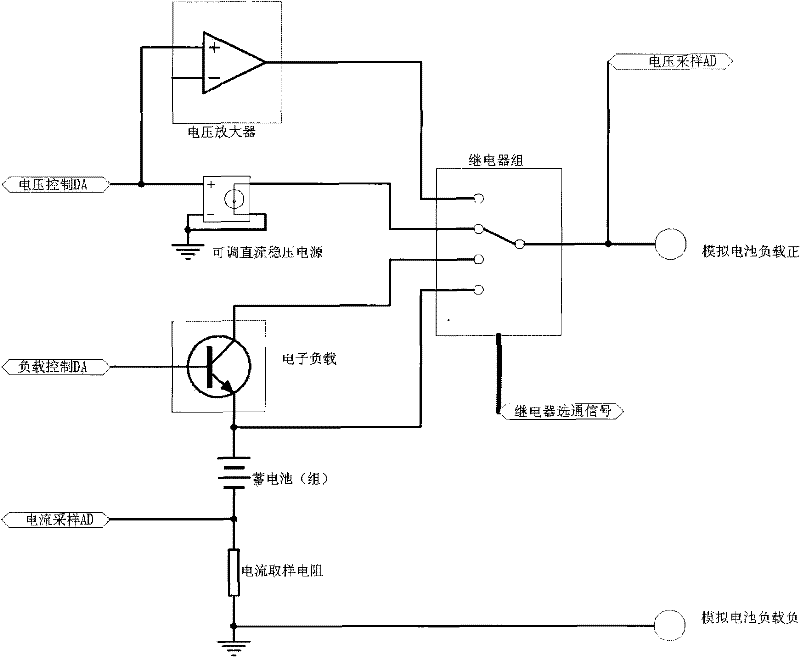

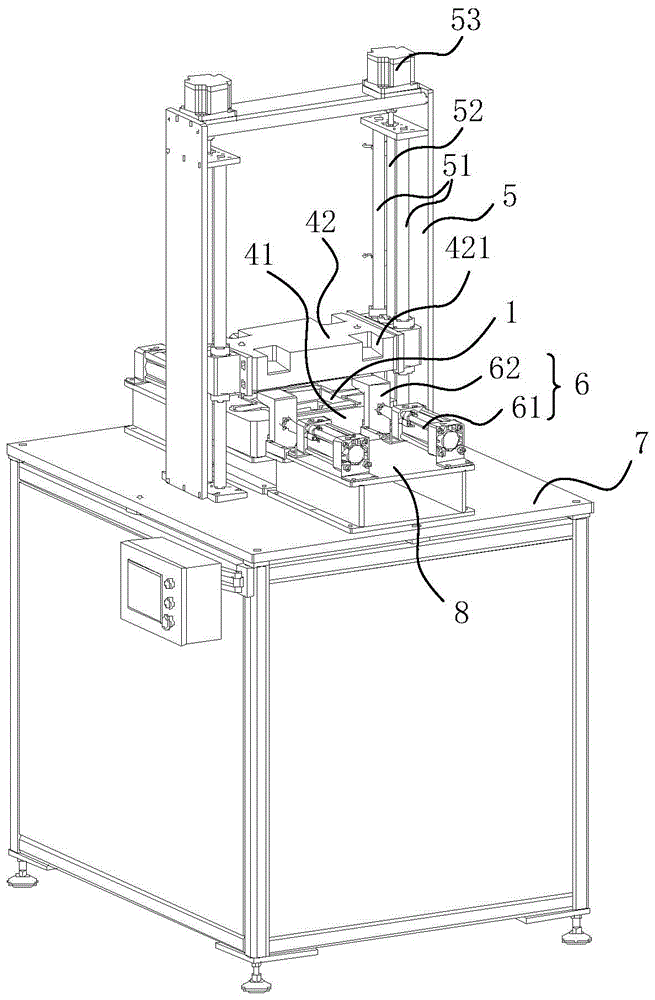

Automatic calibration system of charge/discharge detection instrument of storage battery

ActiveCN101718849BImprove calibration accuracyReduce gross errorElectrical measurementsCommunication interfaceEmbedded system

The invention relates to an automatic calibration system of a charge / discharge detection instrument of a storage battery, which comprises an storage battery simulation load, a sampling control module and an upper computer which is used for collecting a signal of the charge / discharge detection instrument of the storage battery and controls different calibration modes, wherein the upper computer comprises a communication interface and a collection interface, the communication interface is communicated with the charge / discharge detection instrument of the storage battery, the collection interface is communicated with a collection control module and is connected with the sampling control module, the sampling control module is connected with the storage battery simulation load, and the output positive pole and the output negative pole of the storage battery simulation load are connected with the input end of the charge / discharge detection instrument of the storage battery to be calibrated.The invention provides the automatic calibration system of the charge / discharge detection instrument of the storage battery, which can enhance the calibration accuracy of the detection instrument, reduces the generation probability of crude errors greatly, can also save a great deal of labor, shortens the calibration period greatly and is suitable for mass production.

Owner:日照经济技术开发区城市发展投资集团有限公司

Calibration device and method for a pressure module

ActiveCN104792457BShorten the calibration cycleImprove calibration efficiencyFluid pressure measurementEngineeringAtmospheric pressure

The invention discloses a correcting device and method of a pressure module. The correcting device comprises a correcting chamber in which a pressure module base is disposed; the pressure module base comprises a communication board which connects data output ends and correcting coefficient input ends of pressure transmitter modules in the pressure module; the communication board is connected to the correcting device arranged outside the correcting chamber, through a data line; the correcting chamber is provided with a gas hole; a pneumatic adjuster is connected to the correcting chamber through the gas hole; a heater comprises at least one heating plate evenly mounted on the inner wall of the correcting chamber; a pressure acquirer and a temperature acquirer are disposed within the correcting chamber and are connected to the correcting device through data lines. The correcting device and method has the advantages that pressurizing and heating are achieved with the single correcting chamber, heating speed of the correcting chamber is increased, correcting period of the pressure module is shortened, and the pressure module can be corrected more efficiently.

Owner:安徽京芯传感科技有限公司

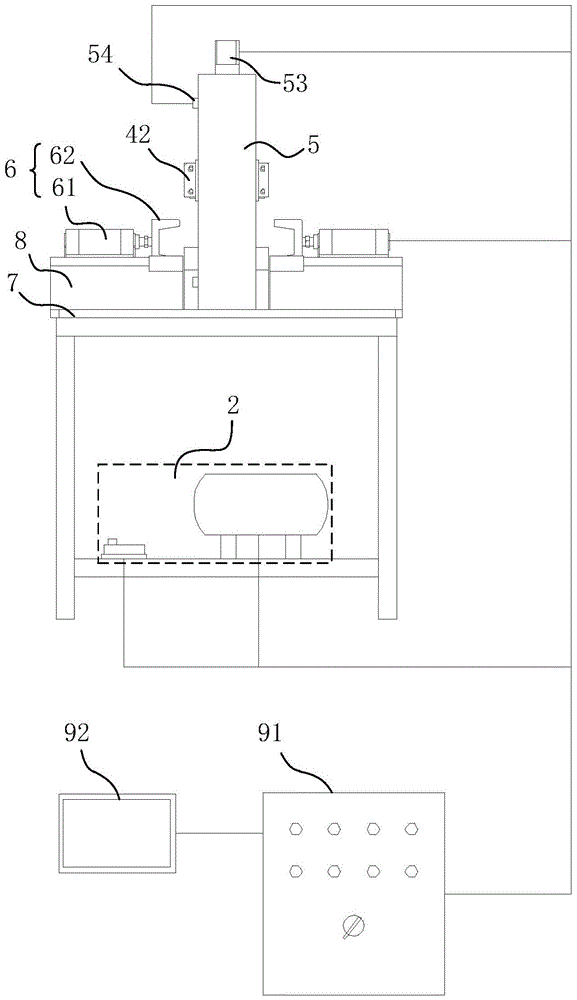

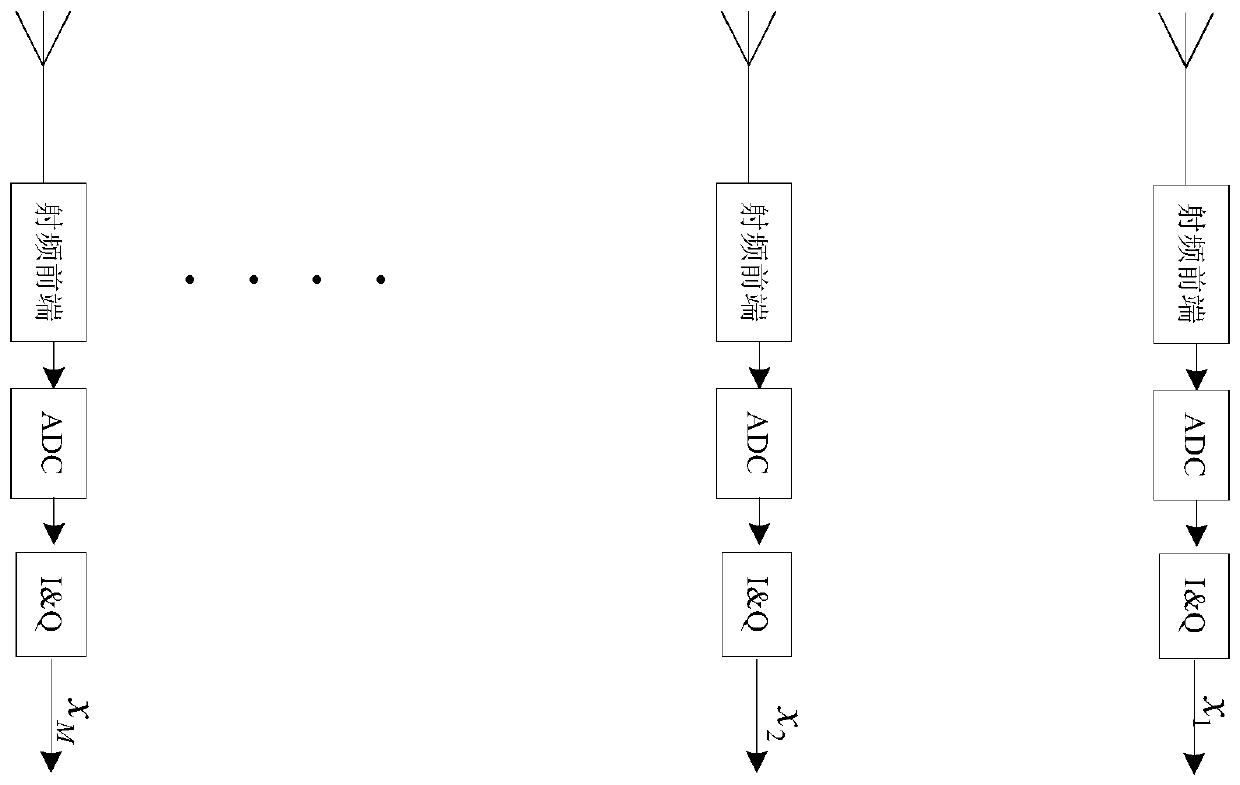

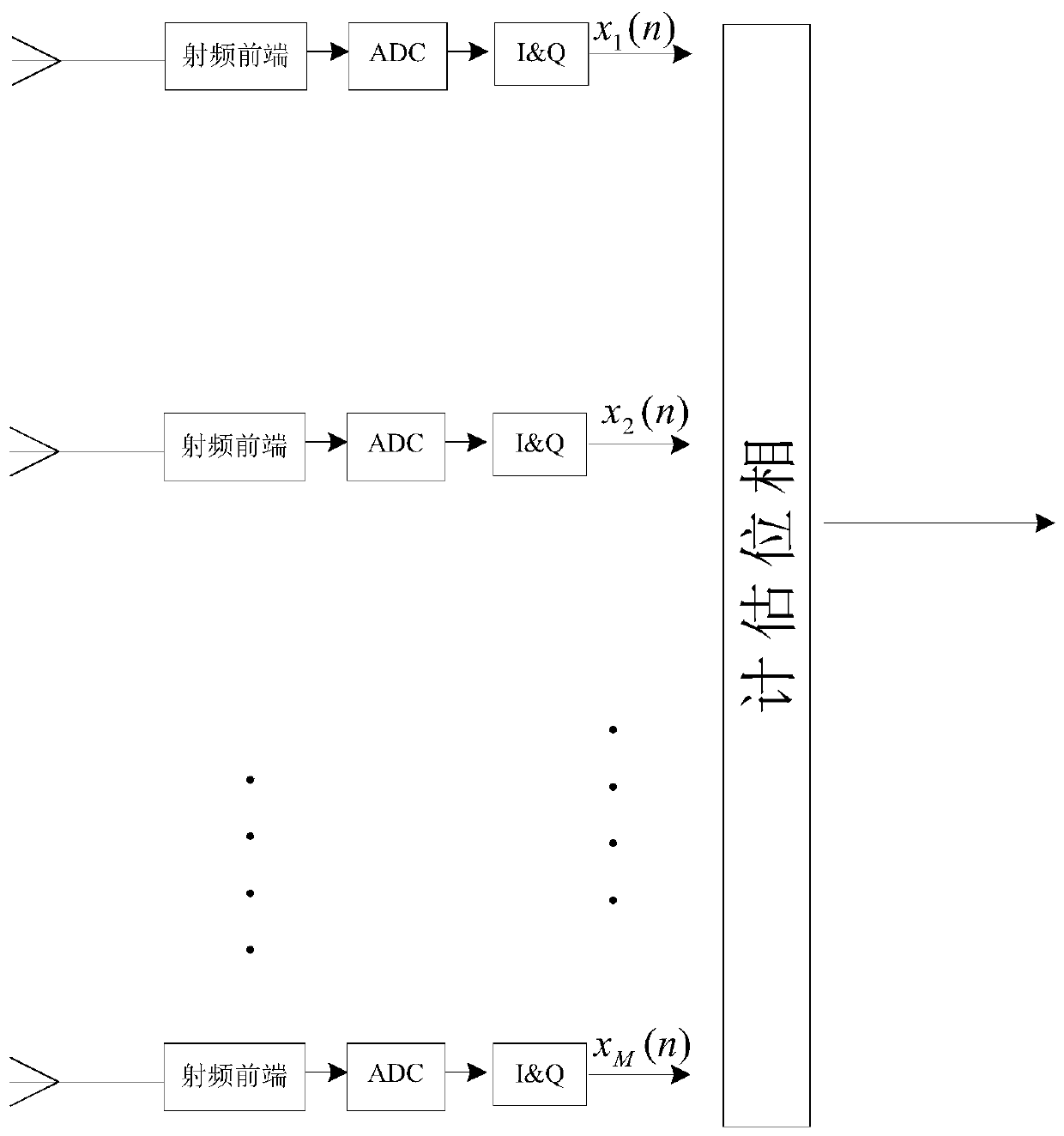

High-precision channel calibration method based on channel phase noise statistics

ActiveCN110896334AReflects good statistical propertiesShorten the calibration cycleReceivers monitoringWave based measurement systemsPhase noiseAlgorithm

The invention discloses a high-precision channel calibration method based on channel phase noise statistics, and the method carries out the multi-time sampling for calculation, and can reflect the statistical characteristics better. Because the channel phase and the phase noise change along with the change of the temperature and the external interference, the calibration period is shortened as much as possible, preferably within 100 milliseconds. In a common channel phase calibration method, only phase noise is regarded as white Gaussian noise, statistical estimation is not accurately carriedout on the characteristics of the noise, loss of channel calibration precision is caused, and the defects are well overcome.

Owner:TIANJIN JINHANG COMP TECH RES INST

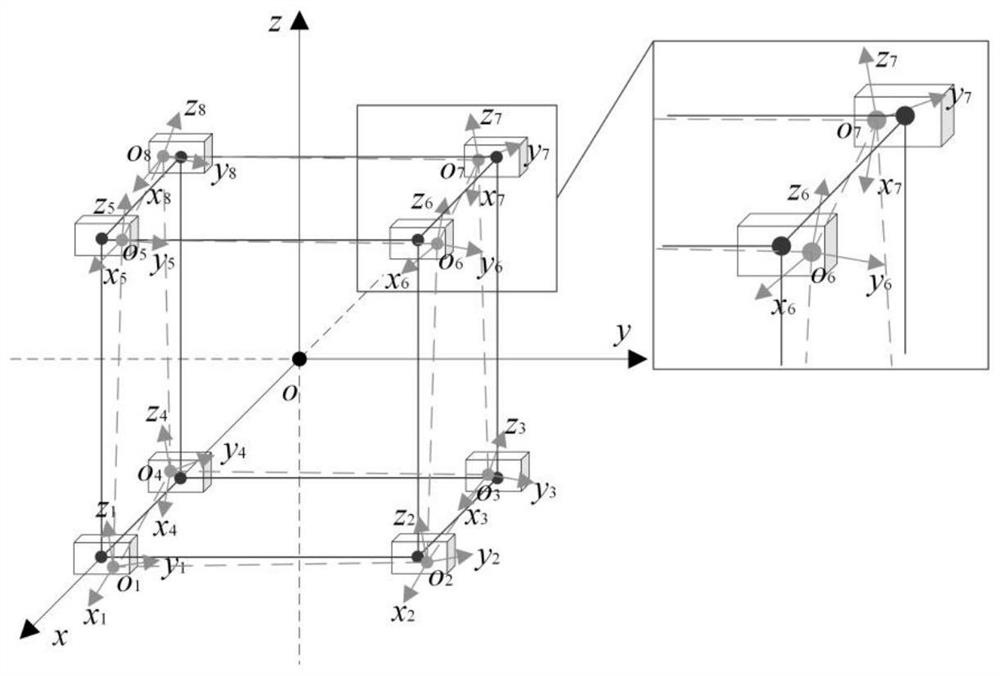

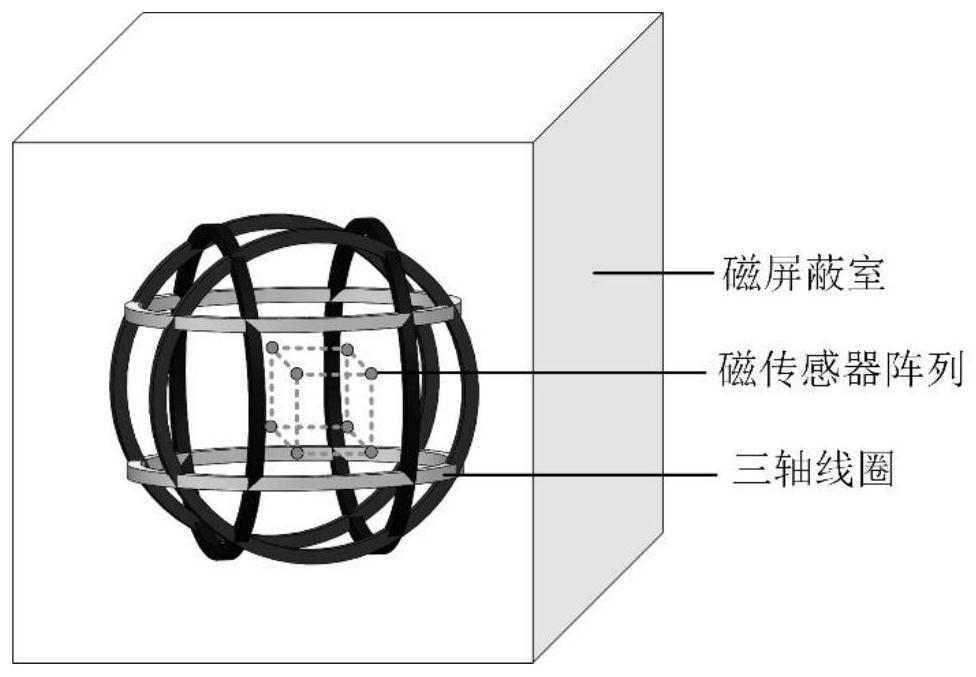

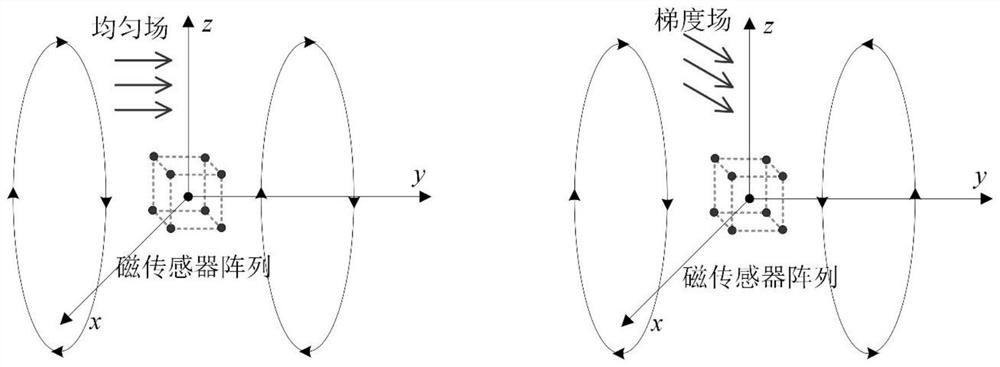

Calibration method of magnetic sensor array

PendingCN114660511ASolve bottlenecksGet rid of dependenceElectrical measurementsMagnetic sensor arraysUniform fieldSensor array

The invention discloses a calibration method of a magnetic sensor array, and belongs to the technical field of magnetic target positioning. The calibration method of the magnetic sensor array comprises the following steps of S100, electrifying coaxial coils in the same direction to enable a uniform field-gradient field composite coil to be in a uniform field mode, and calibrating a self error parameter and an output misalignment error parameter of the magnetic sensor array by utilizing the uniformity of a coil magnetic field; and S200, reversely electrifying the coaxial coils to enable the uniform field-gradient field composite coil to be in a gradient field mode, and calibrating the position deviation of the test points of the magnetic sensor array by using the coordinate coordination between the two modes and the spatial resolution of the gradient magnetic field. According to the invention, background magnetic interference is eliminated, the calibration precision is further improved, and the calibration efficiency is greatly improved. Meanwhile, the problem that two kinds of error parameters including test point position deviation and output misalignment cannot be calibrated is solved, and a magnetic sensor array calibration system is further improved.

Owner:HARBIN INST OF TECH

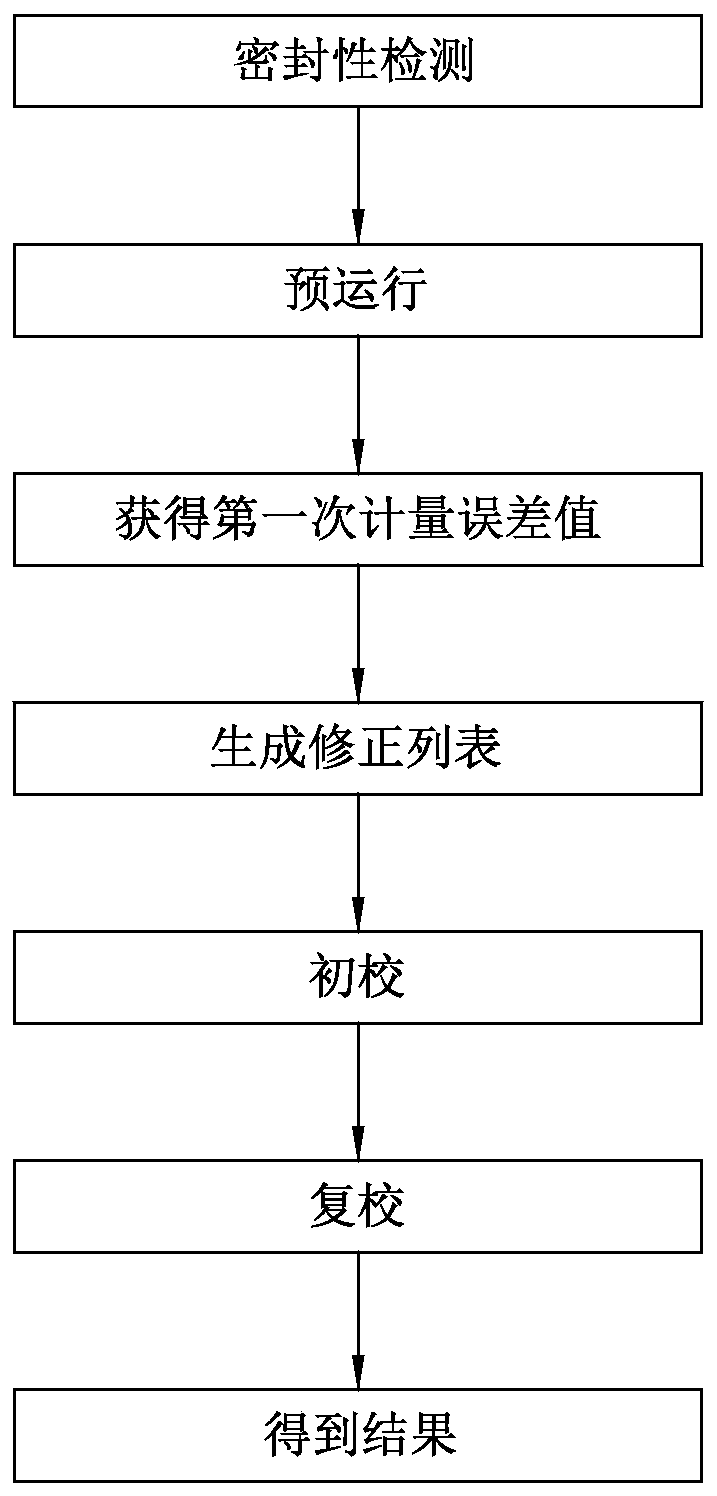

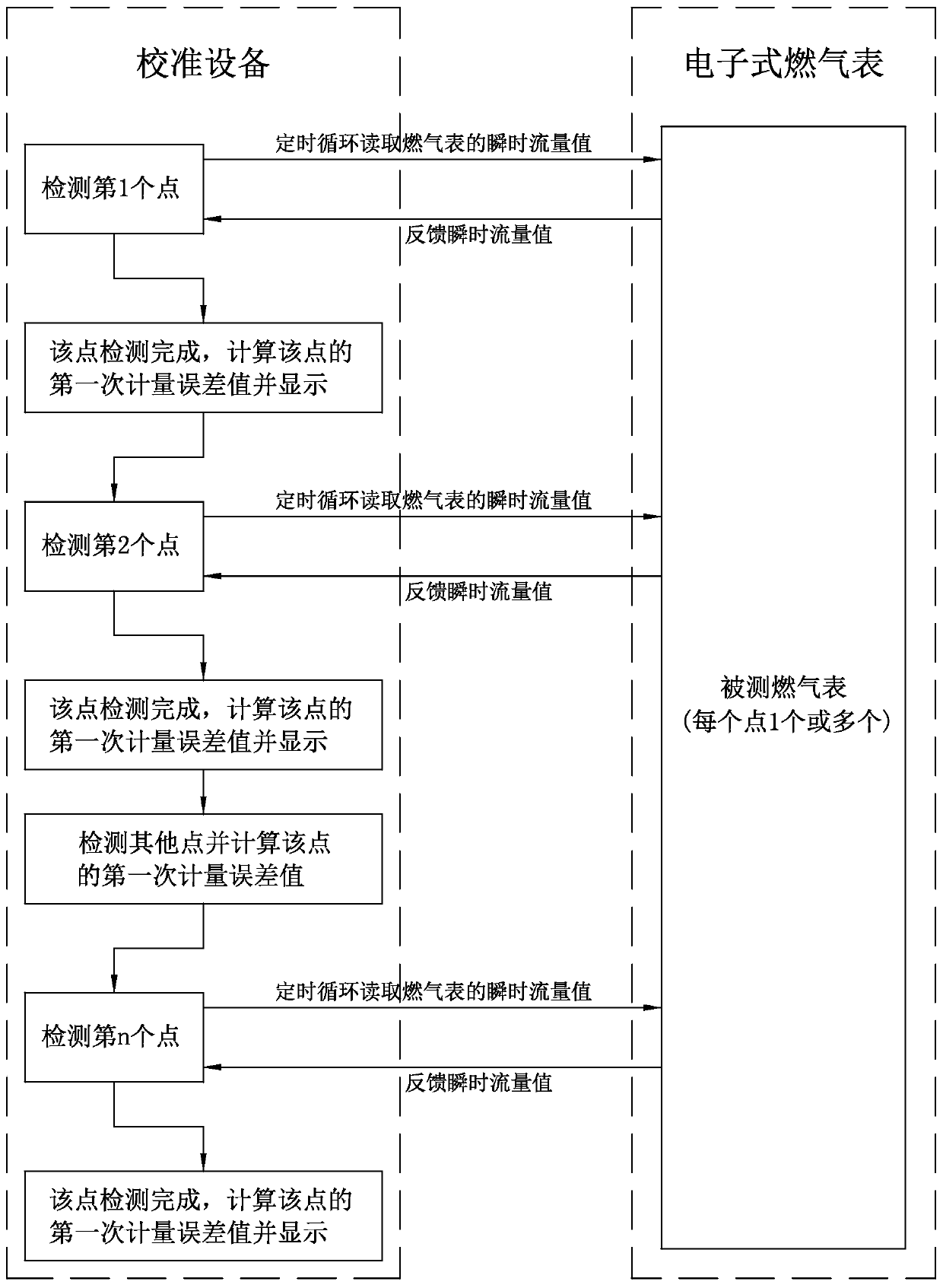

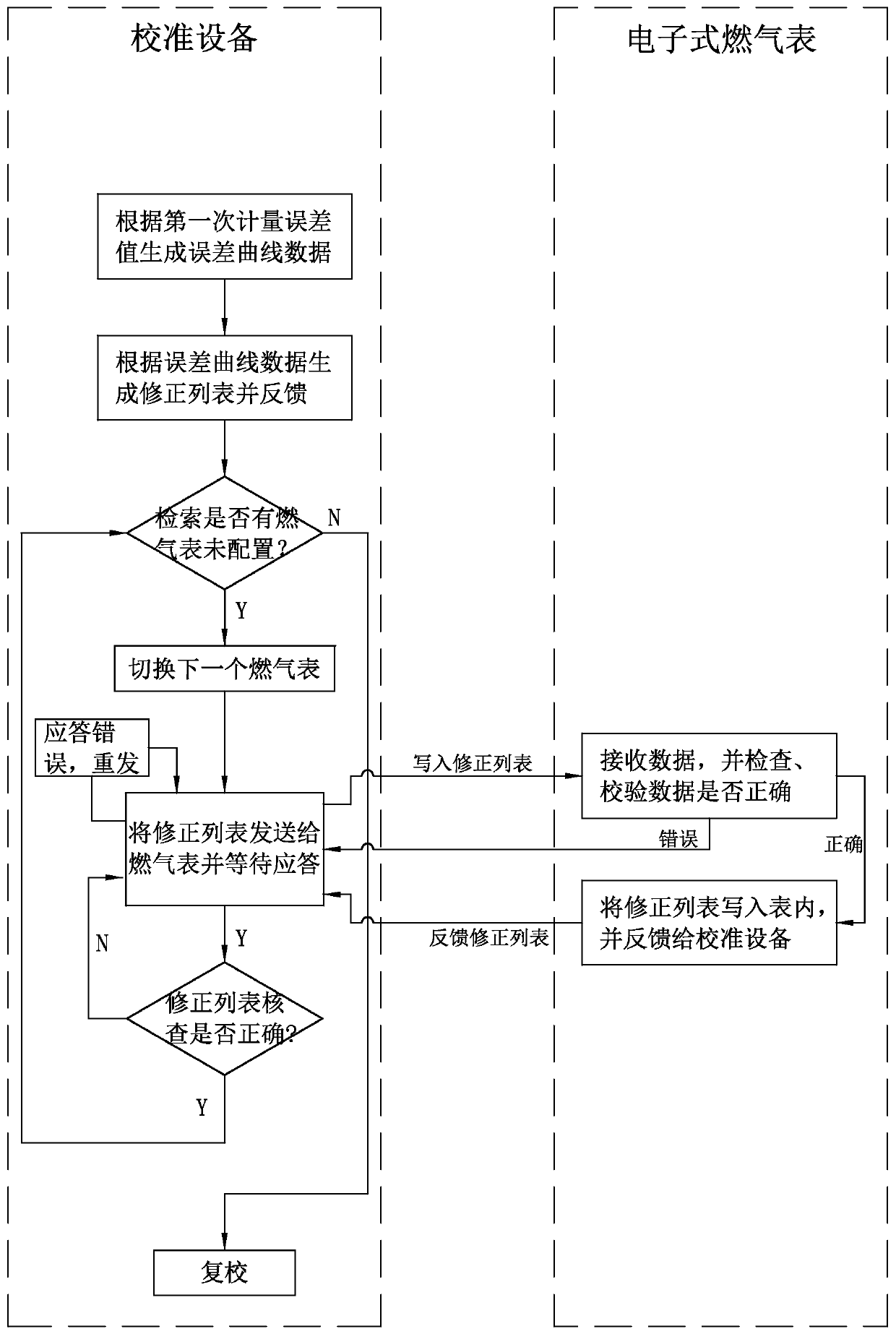

Calibration method of electronic gas meter

ActiveCN111157081AImprove accuracyGuaranteed pass rateTesting/calibration apparatusGas meterMechanical engineering

The invention discloses a calibration method of an electronic gas meter, which belongs to the technical field of gas meters, and comprises the following steps: calibration equipment generates a correction list of each gas meter according to a first metering error value of each gas meter, writes the correction list into the gas meter to finish initial calibration, and recalibrates the gas meter. The calibration equipment can calibrate all the gas meters corresponding to all the flow detection points at a time, and the calibration efficiency can be improved. The correction list is checked between the gas meter and the calibration equipment, so that the correctness of the correction list written into the gas meter is effectively ensured, and the calibration accuracy of the gas meter is improved. And after initial calibration is completed, the gas meters are re-calibrated, so that the calibration accuracy is further improved, and the percent of pass of the calibrated gas meters is ensured.

Owner:GOLDCARD HIGH TECH

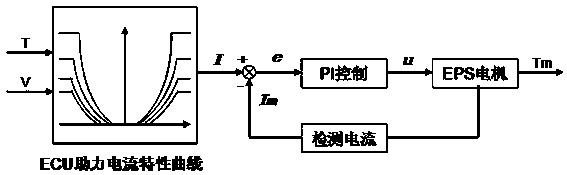

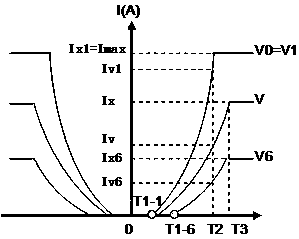

A Follow-up Calibration Method for Electric Power Steering Current Characteristics of Automobile

ActiveCN106882260BVisualization of the calibration processEasy to operateElectrical steeringWorkloadFeature parameter

The invention discloses a follow-up calibration method for the automobile brush-electric-power-steering assist current characteristics. The automobile brush-electric-power-steering assist current characteristics can be matched with automobile related physical parameters, parameter setting of an electronic control unit (for short, ECU) in EPS is adjusted and completed, and the best assist characteristics are output through EPS to meet the requirements of an automobile for the steering performance. Meanwhile, the follow-up calibration method is also suitable for the ECU parameter calibration process in the laboratory state to complete the EPS assist characteristics close to actual-automobile applications, and the calibration workloads of an actual automobile are completed. According to the follow-up calibration method, the EPS assist characteristics are equivalent to the characteristics of assist currents I output by the ECU, a characteristic curve of the assist currents I is calibrated, the driving speed V and the steering hand power T of the automobile and all the parameters of the characteristic curve of the assist currents I are relationally designed, parameter setting of a small quantity of key characteristic points is applied so that whole course calibration of the other characteristic parameters can be adjusted in a follow-up mode, visualization is achieved, and the follow-up calibration method is accurate, easy and convenient to operate and short in period.

Owner:DALIAN INNOVATION PARTS MANUFACTURING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com