Hopper scale calibration device based on digital sensor

A digital sensor and calibration device technology, applied in the direction of weighing equipment testing/calibration, etc., can solve the problems of long calibration time, unsatisfactory, cumbersome and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

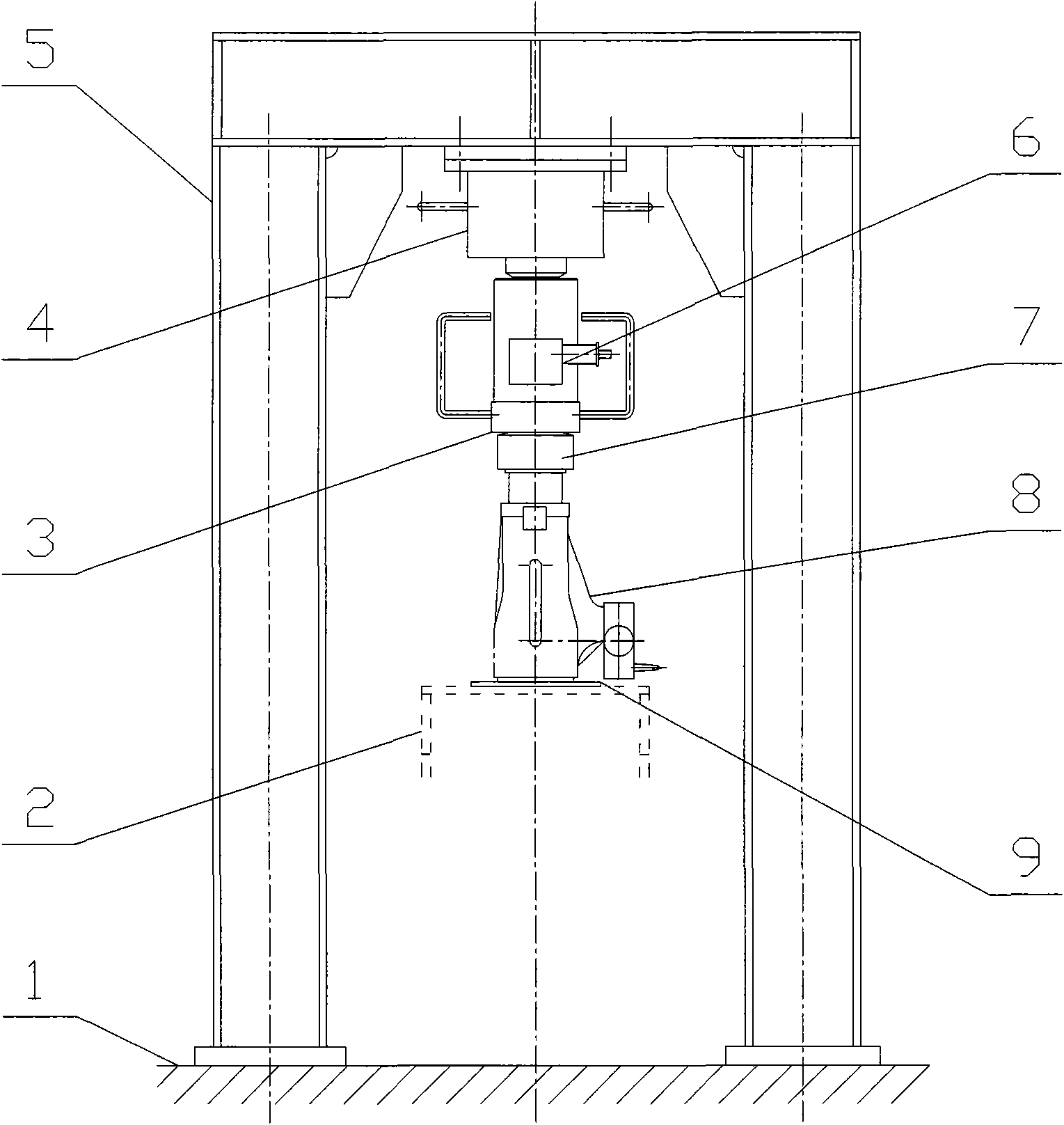

[0022] see figure 1 , which is the present invention, which is a structural schematic diagram of a digital sensor-based hopper scale calibration device of the present invention. As shown in the figure: it includes a frame 5 whose lower end can be connected to the hopper scale platform, a buffer 4 is arranged on the frame 5, and a digital load cell 6 is arranged under the buffer 4, and the lower end of the digital load cell 6 passes through The connecting piece 7 is connected to the upper end of a jack 8, and the lower end of the jack 8 can be connected to the hopper support 2.

[0023] The lower end of the digital load cell 6 is connected to the upper end of the connector 7 through the sensor fixing rubber 3 .

[0024] The jack 8 is connected with the hopper support 2 through the jack positioning part 9 at its lower end.

[0025] The frame 5 frame is a key part of the calibration device, and its rigidity and stability are particularly important due to the relatively complex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com