Offset correction system and correction method for tower-type heliostat

A calibration system and heliostat technology, applied in solar heating systems, solar collector controllers, solar thermal devices, etc., can solve the problems of poor timeliness of calibration results and long calibration periods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

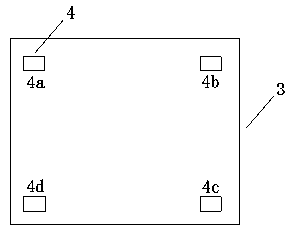

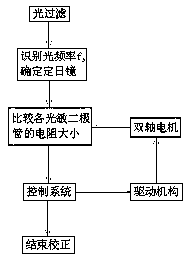

[0036] The tower-type heliostat deviation correction system of the present invention includes a light filtering device 2, a heliostat 1, a photosensitive diode 4, a control system, a driving mechanism, and a two-axis motor (horizontal motor and pitch motor). The light filtering device is located on the surface of the heliostat, and the frequency range of the filtered light is 3.8X10 14 -7.9X10 14 HZ, the database corresponding to the frequency of the heliostat and the reflected light is pre-established in the control system. The sunlight is irradiated on the heliostat through the light filtering device, and then the heliostat reflects the filtered sunlight to the heat collector. A photosensitive diode is installed at each of the four corners of the heat collector. The control sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com