A Follow-up Calibration Method for Electric Power Steering Current Characteristics of Automobile

A current characteristic, electric steering technology, applied in electric steering mechanism, power steering mechanism, steering mechanism and other directions, can solve the problem of long calibration period of steering performance requirements, achieve easy analysis and mass production application, stable feel adjustment ability, Avoid the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

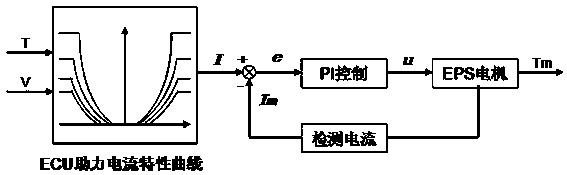

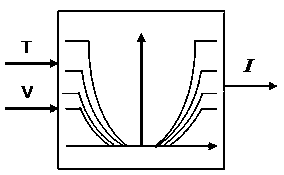

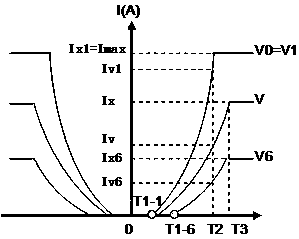

[0026] Such as figure 1 As shown, the working principle of EPS is that when the driver turns the steering wheel, the ECU obtains the steering hand signal T from the torque sensor of the EPS, and obtains the vehicle speed signal V from the vehicle speed sensor, and the parameters and coefficients completed by the ECU according to the calibration, Carry out calculation processing and output the ideal assist current I, and then through the PI control of the current loop, the current Im input to the EPS motor can be tracked in time and reach the ideal assist current I, thereby controlling the EPS motor torque Tm through the reduction mechanism Increased torque output to meet steering performance requirements. Therefore, if figure 2 Whether the assist current I output by the ECU assist current control module shown can meet the steering performance requirements, the key l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com