Urea-SCR control parameter off-line calibration system and calibration method

A technology for calibrating system and controlling parameters, applied in the direction of chemical process analysis/design, etc., can solve the problems of high cost, high work intensity, long cycle, etc., and achieve the effect of reducing work intensity, reducing test content, and shortening the calibration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

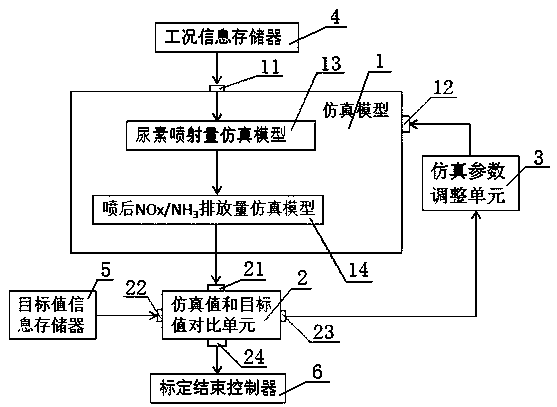

[0040] see figure 1 , a Urea-SCR control parameter offline calibration system, including a simulation model 1, a simulation value and a target value comparison unit 2, a simulation parameter adjustment unit 3, the simulation model 1 includes a No. 1 input port 11, a No. 2 input port 12, Urea injection quantity simulation model 13, NOx or NH after injection 3 The discharge amount simulation model 14, the input port of the urea injection amount simulation model 13 is connected with the output port of the working condition information memory 4 through the first input port 11, and the output port of the urea injection amount simulation model 13 is passed through the NOx / NH 3 The emission simulation model 14 is connected with the first input port 21 of the simulation value and target value comparison unit 2, and the second input port 22 of the simulation value and target value comparison unit 2 is connected with the output port of the target value information memory 5, and the simu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com