AMT automatic gearbox power transmission system assembly testing platform

A technology of power transmission system and automatic transmission, applied in the field of test platform, can solve the problems of inability to test the electronic communication capability of AMT transmission, failure to consider the performance of the drive system, integrated control of the battery characteristic control system, etc., to shorten the cycle, reduce risks and cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

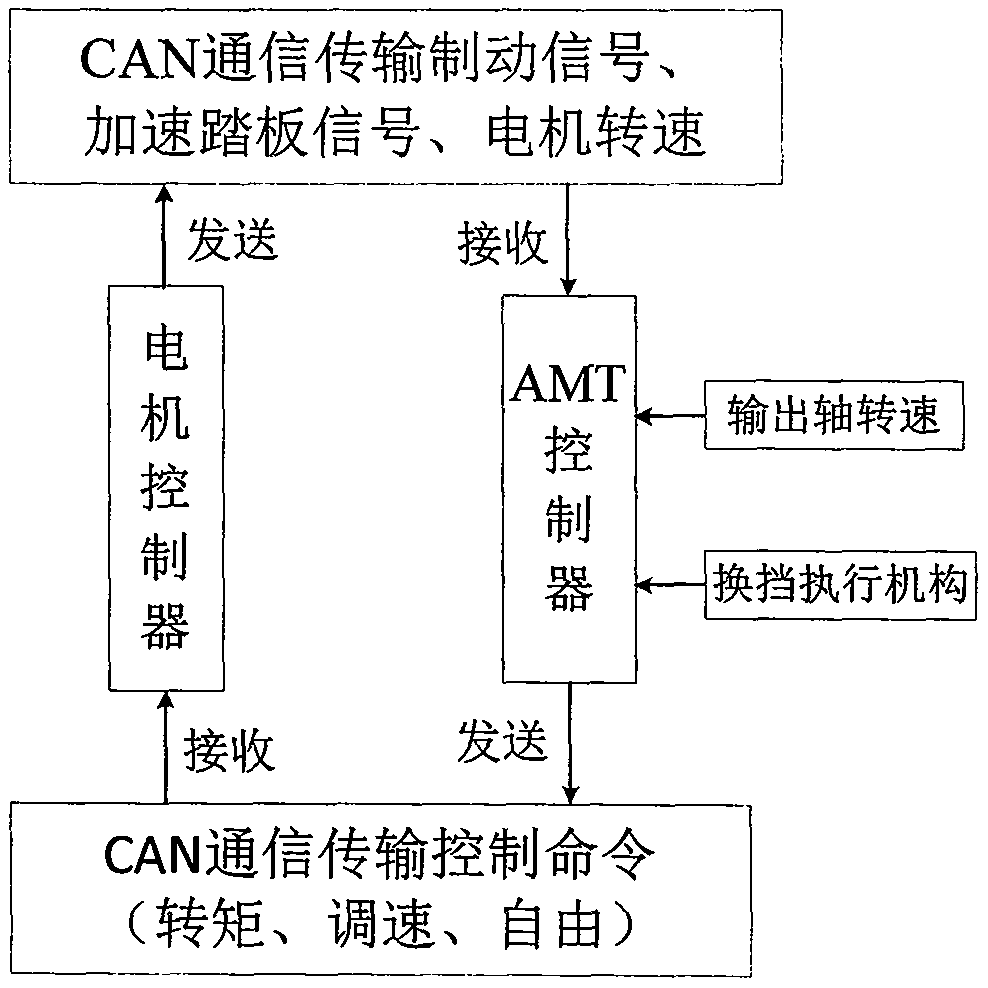

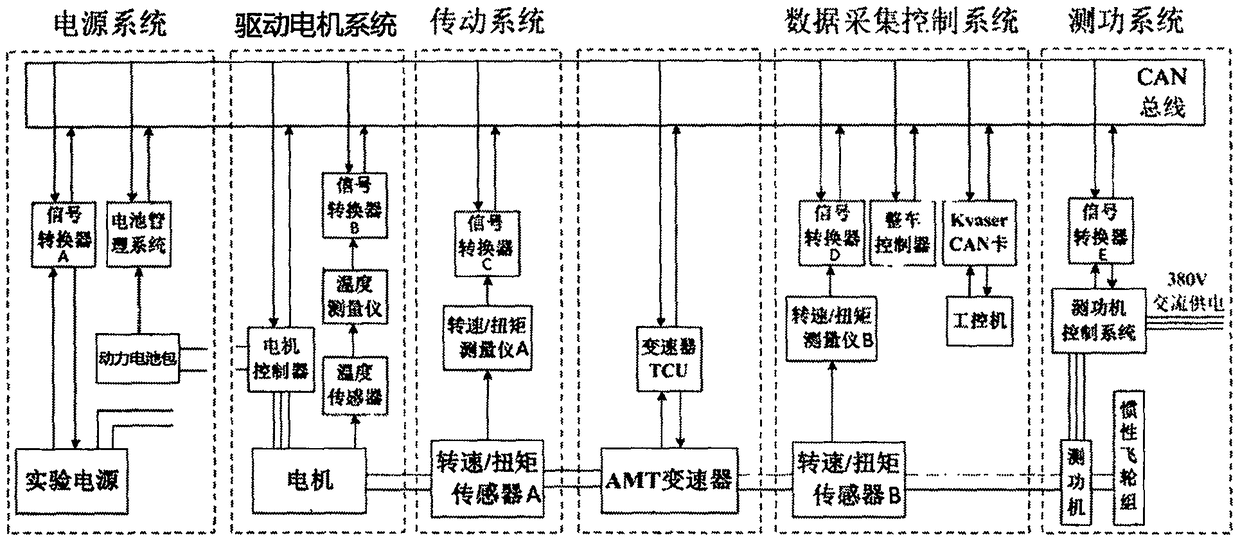

[0018] Example 1-2: See figure 1 , an AMT automatic transmission power transmission system test platform, consists of a mechanical part and a control part. The mechanical part of the test platform is composed of dynamometer, speed / torque sensor, drive motor, AMT transmission, power battery or experimental power supply and inertial flywheel; the control part of the test platform is composed of industrial computer, dynamometer control system, motor controller, It is composed of speed / torque measuring instrument, temperature measuring instrument, vehicle controller and battery management system, in which: the power battery or experimental power supply is connected to the driving motor through wires; the driving motor is connected to the AMT transmission through a transmission shaft , the speed / torque sensor A is installed between the output shaft of the driving motor and the AMT transmission; the AMT transmission is connected with the dynamometer through a transmission shaft, and...

Embodiment 2

[0020]Embodiment 2, on the basis of Embodiment 1, the data collection control system, the specific collection information includes battery management system, temperature measurement module, motor controller, speed / torque sensor A, dynamometer control system, experimental power supply, vehicle A controller, an analog input module and a gearbox TCU, wherein the battery management system is connected to the industrial computer through CAN communication, and feeds back battery pack voltage / current / state of charge (SOC) and battery status information; the temperature measurement module , the temperature sensor is connected with the temperature measuring instrument through the power line, and then the communication mode is converted into CAN communication through the signal converter, and the CAN communication is connected with the industrial computer to realize the data collection of the temperature information of the motor; the motor controller, through the CAN communication and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com