Voltage sensor suitable for field measurement of transformer substation

A voltage sensor and on-site measurement technology, applied in the direction of measuring electrical variables, measuring devices, instruments, etc., can solve the problems of inapplicable electronic voltage transformer calibration, ferromagnetic resonance caused by live connection to the power grid, and large equipment size and weight and other issues to achieve the effect of improving reliability and economy, avoiding loss and inconvenience, and improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

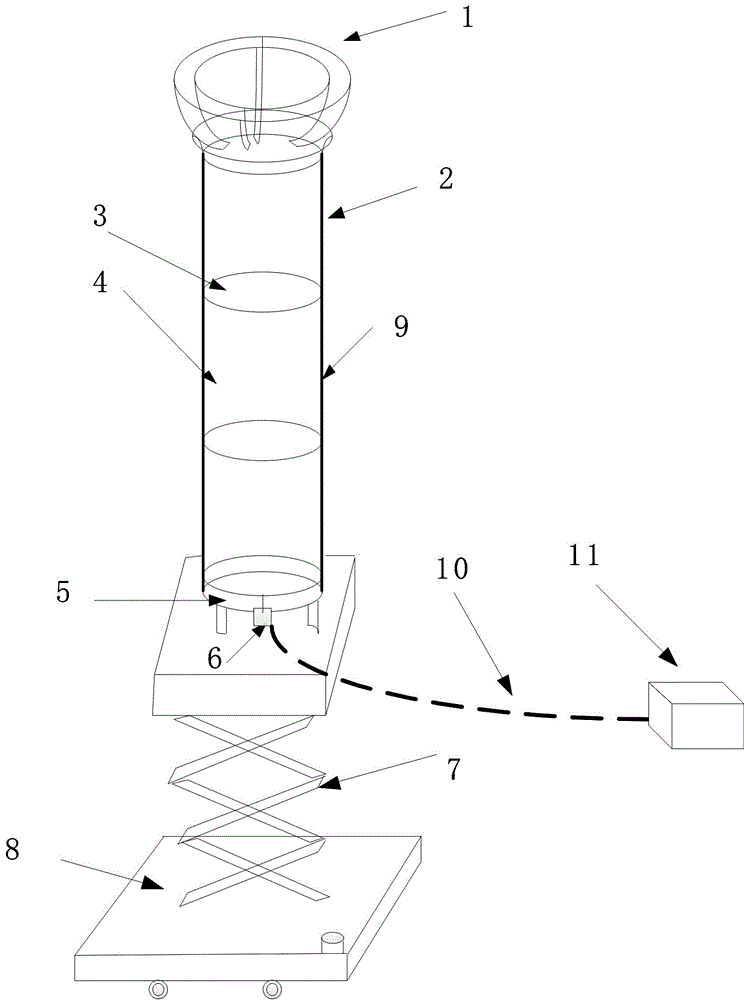

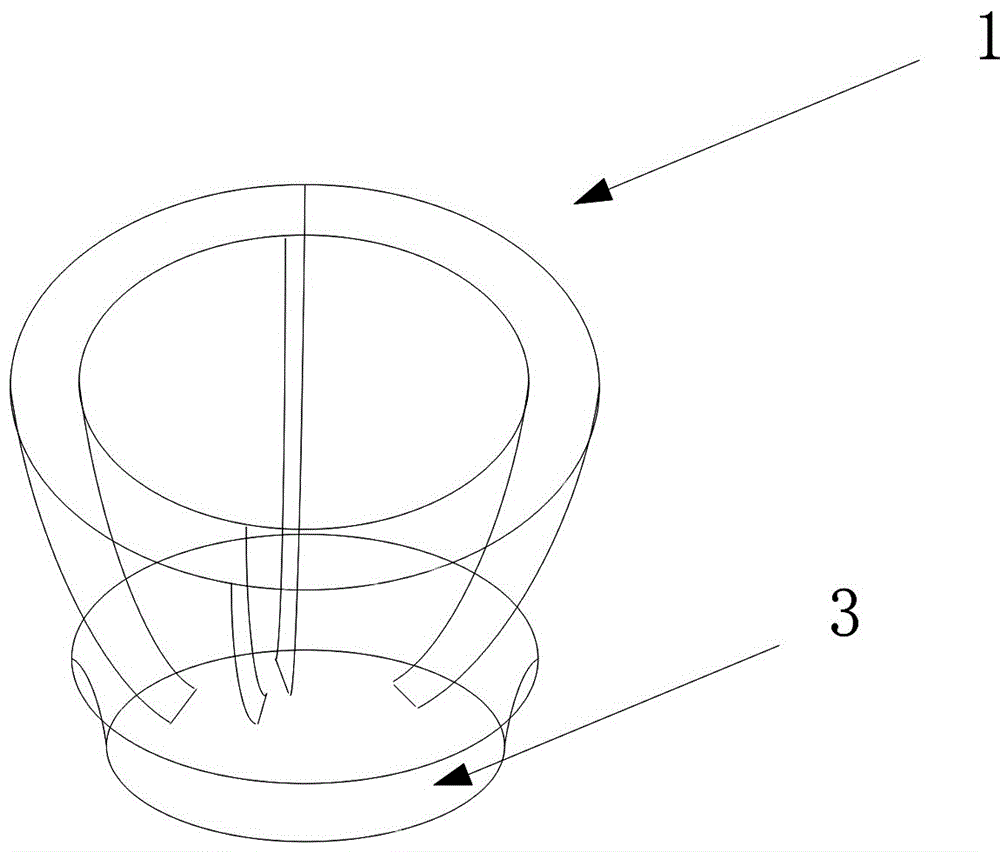

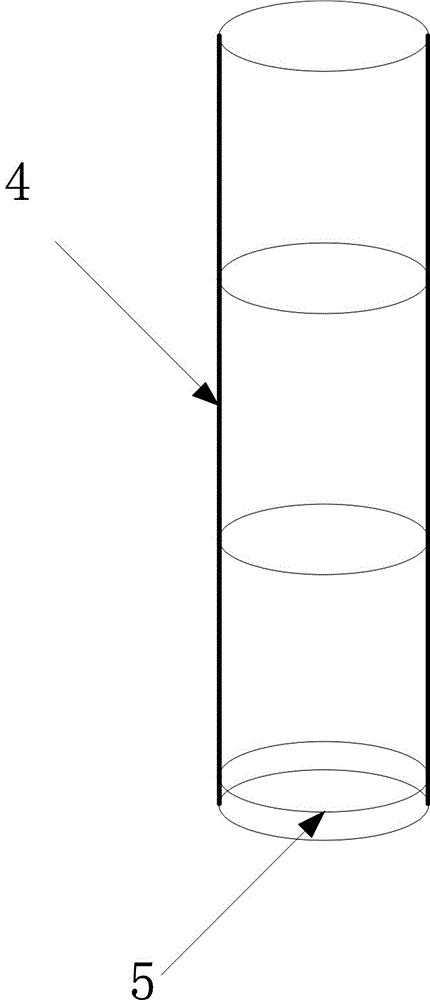

[0025] Such as Figure 1~Figure 5 As shown, a voltage sensor suitable for on-site measurement in substations includes a voltage equalizing ring 1 , a primary voltage sensing unit 2 , a collection and transmission unit 6 , and a lifting platform 7 .

[0026] The primary voltage sensing unit 2 uses a parallel plate capacitor to form a high-voltage capacitor 4 and a low-voltage capacitor 5, which are filled with air to form a gas capacitor, which has good insulation, and its volume and weight do not change much when the voltage level increases , very suitable for on-site verification. The high-voltage capacitor 4 is composed of three gas capacitors with three pole spacings of 1.5m; the low-voltage capacitor 5 is composed of one gas capacitor with a pole spacing of 0.04m; the high-voltage capacitor 4 and the low-voltage capacitor 5 are divided in series. When the high-voltage transmission circuit is 220kV, the voltage signal U generated in the low-voltage capacitor 5 1 It is abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com