Calibration method of balance with air bridge of wind tunnel strain considering pressure influence

A calibration method, air bridge technology, applied in the wind tunnel field, can solve the problems that the difference between the calibration state and the test state cannot be completely eliminated, the calibration cycle of the balance with air is long, and the quality of the wind tunnel test is restricted, so as to improve the efficiency of research and development and shorten the calibration The effect of cycle and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in combination with specific embodiments.

[0036] The invention utilizes the working formula calibrated by the balance belt air bridge under a limited number of pressure conditions to fit and generate a general balance formula containing pressure parameters. Including the following steps:

[0037] Step A: According to the characteristics of the wind tunnel test model, determine the pressure range of the balance with air bridge calibration.

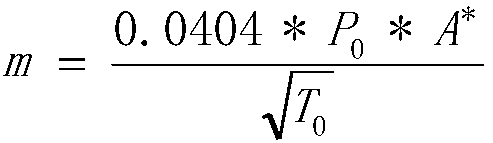

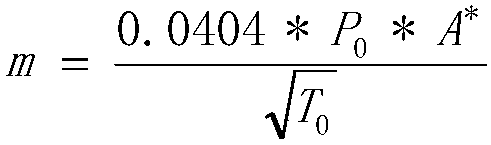

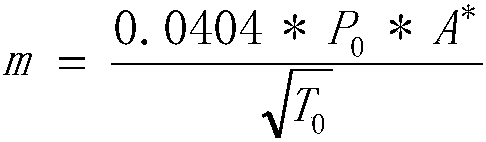

[0038] In this example, according to the throat outlet area (theoretical design value) and flow rate (given value) of all nozzles used in the wind tunnel test model, the actual measured ambient pressure (static pressure) at the outlet of the nozzle, and the flow rate of the airflow in the nozzle The total temperature value is the temperature value, and the total temperature value is a fixed value. In one embodiment of the present application, the total temperature val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com