Guide plate and chain

A technology of guide plates and chains, applied in the direction of belts/chains/gears, chain elements, transmission chains, etc., can solve the problems of reduced sliding friction, complex production process, etc., and achieve the effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] [Mode of Embodiment of the Invention]

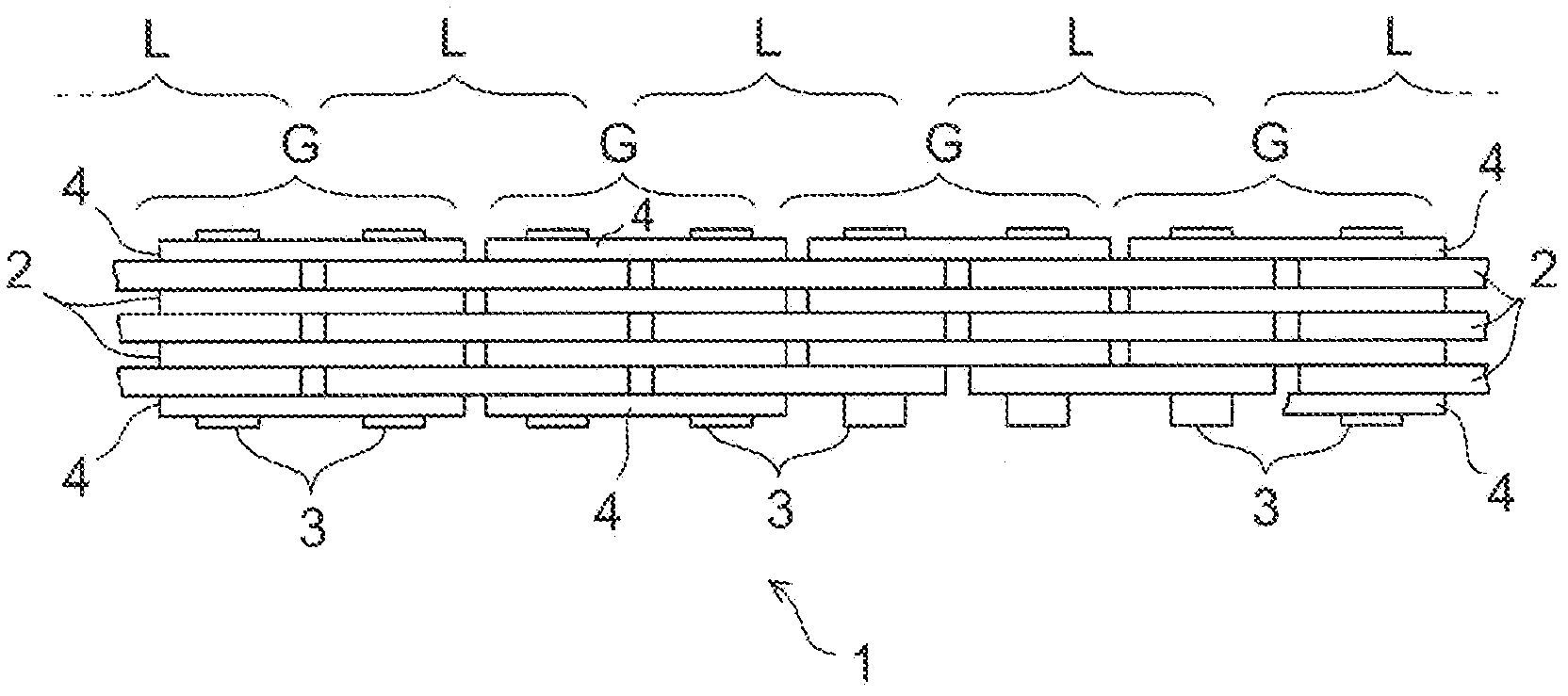

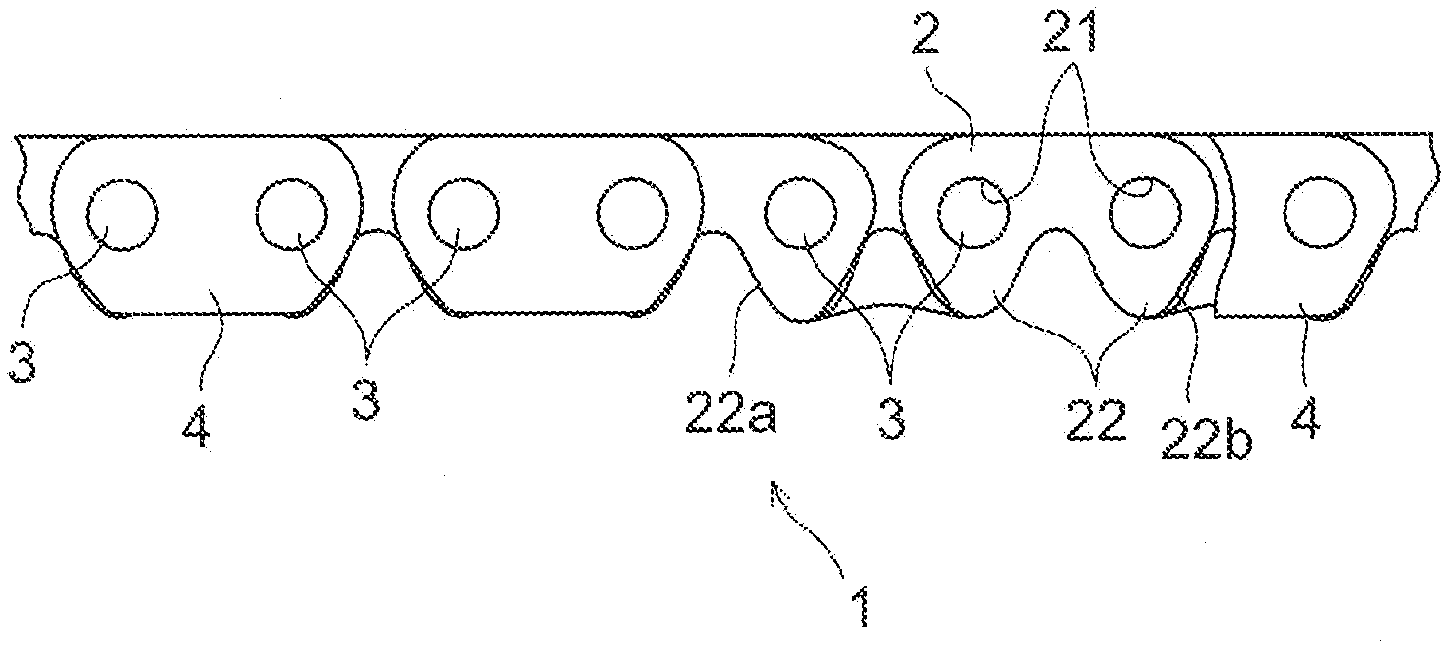

[0052] An exemplary embodiment of the present invention will be described below with reference to the accompanying drawings. Figure 1 to Figure 6 A guide plate according to an exemplary embodiment of the present invention, and a silent chain equipped with a plurality of such guide plates are shown; the same reference symbols are used in the figures to designate the same or corresponding parts.

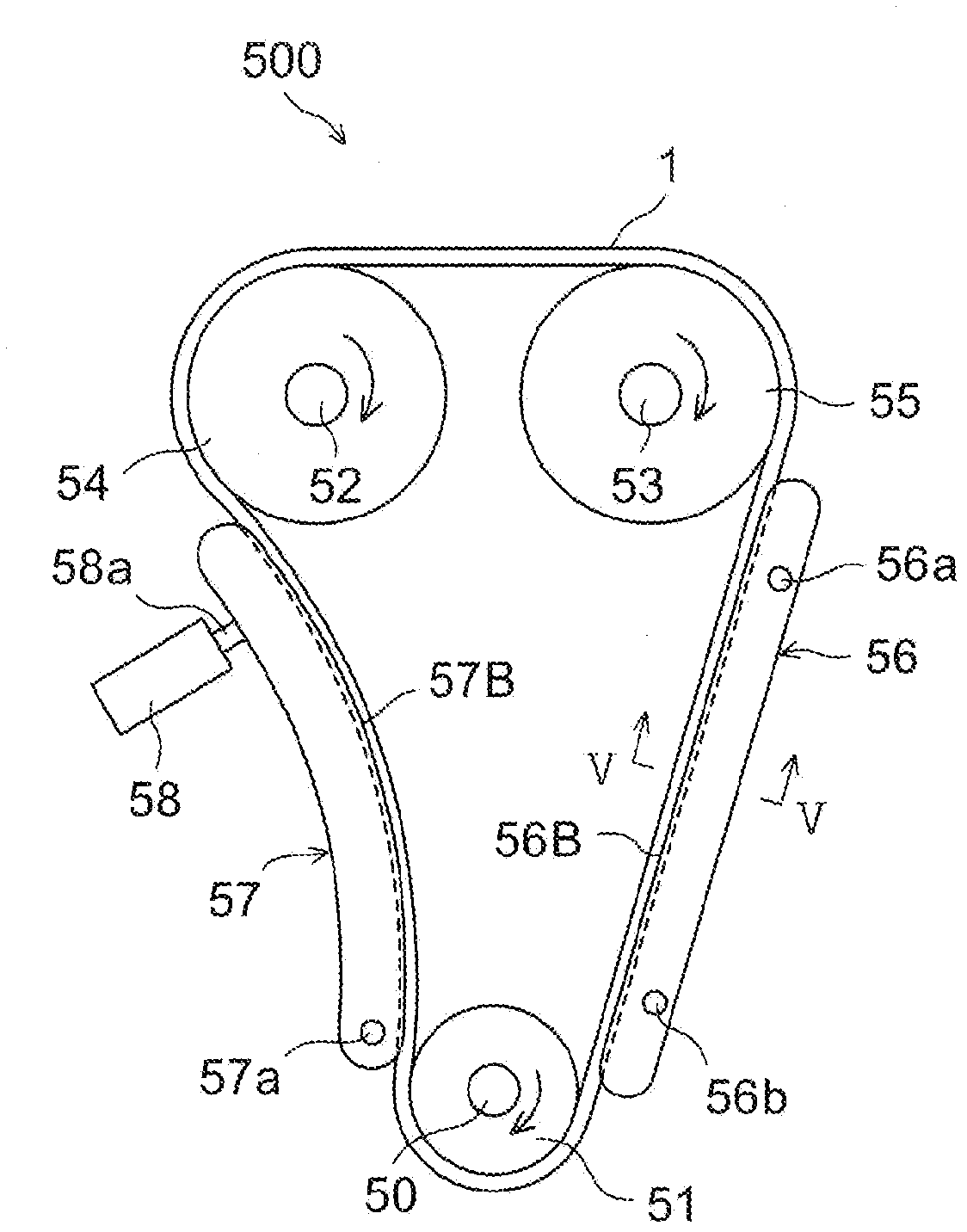

[0053] as in figure 1 As shown in , a camshaft timing system 500 in an engine using such a silent chain according to an exemplary embodiment of the present invention is equipped with: a crank sprocket 51 attached to a crankshaft 50; correspondingly attached to the cam sprockets 54, 55 on the two camshafts 52, 53; and a silent chain 1 wound around these sprockets 51, 54, 55. s, figure 1 The multiple clockwise arrows in indicate the direction of rotation of the sprockets 51 , 54 , 55 .

[0054] A chain guide 56 for guiding the travel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com