Offshore multi-directional self-elevating petroleum drilling platform

A self-elevating platform, multi-directional technology, applied in the field of machinery, can solve problems such as inability to drill in multiple directions, platform overturning, foundation damage, etc., to achieve high promotion and application value, reduce operation preparation costs, and ensure the effect of safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

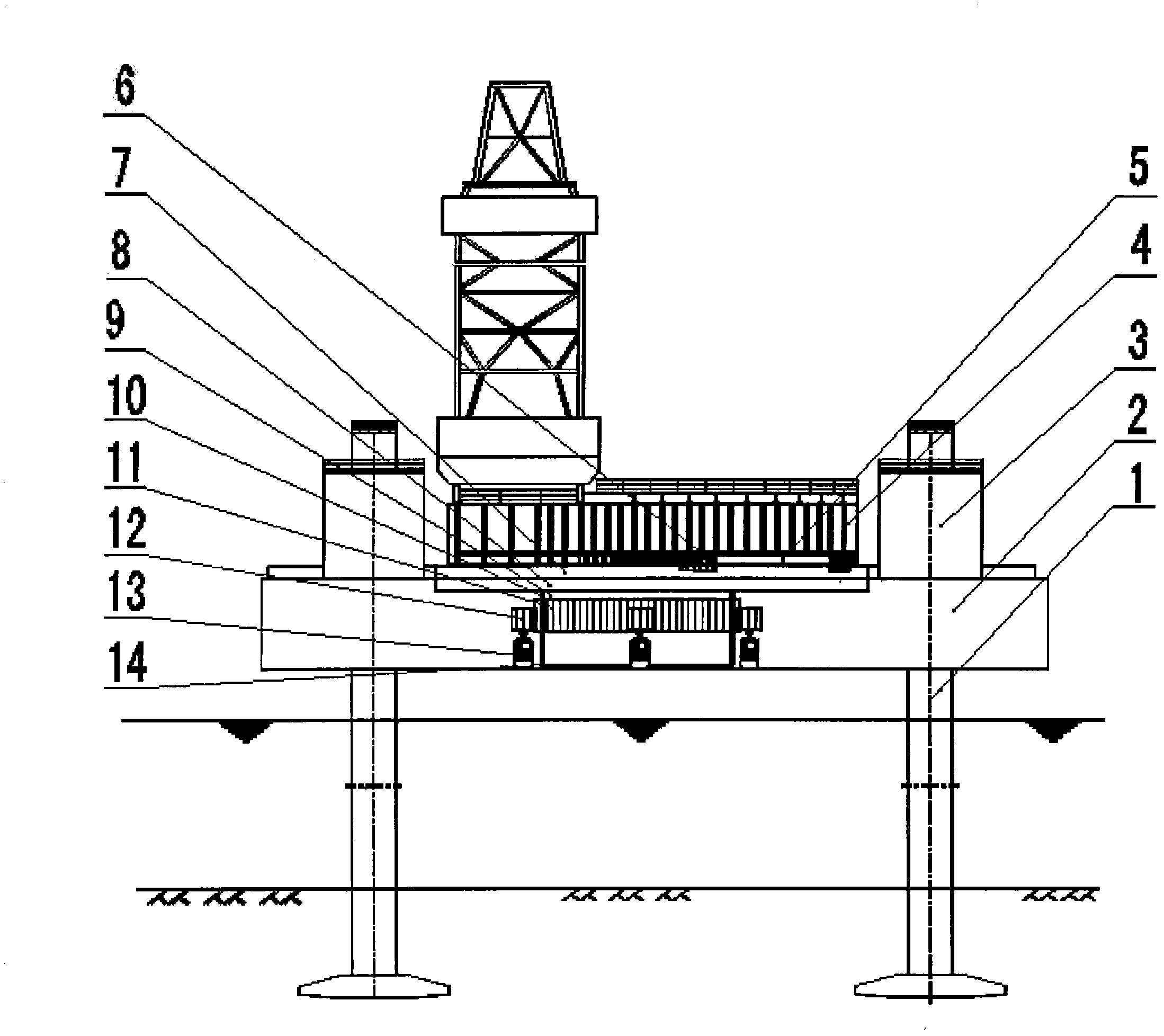

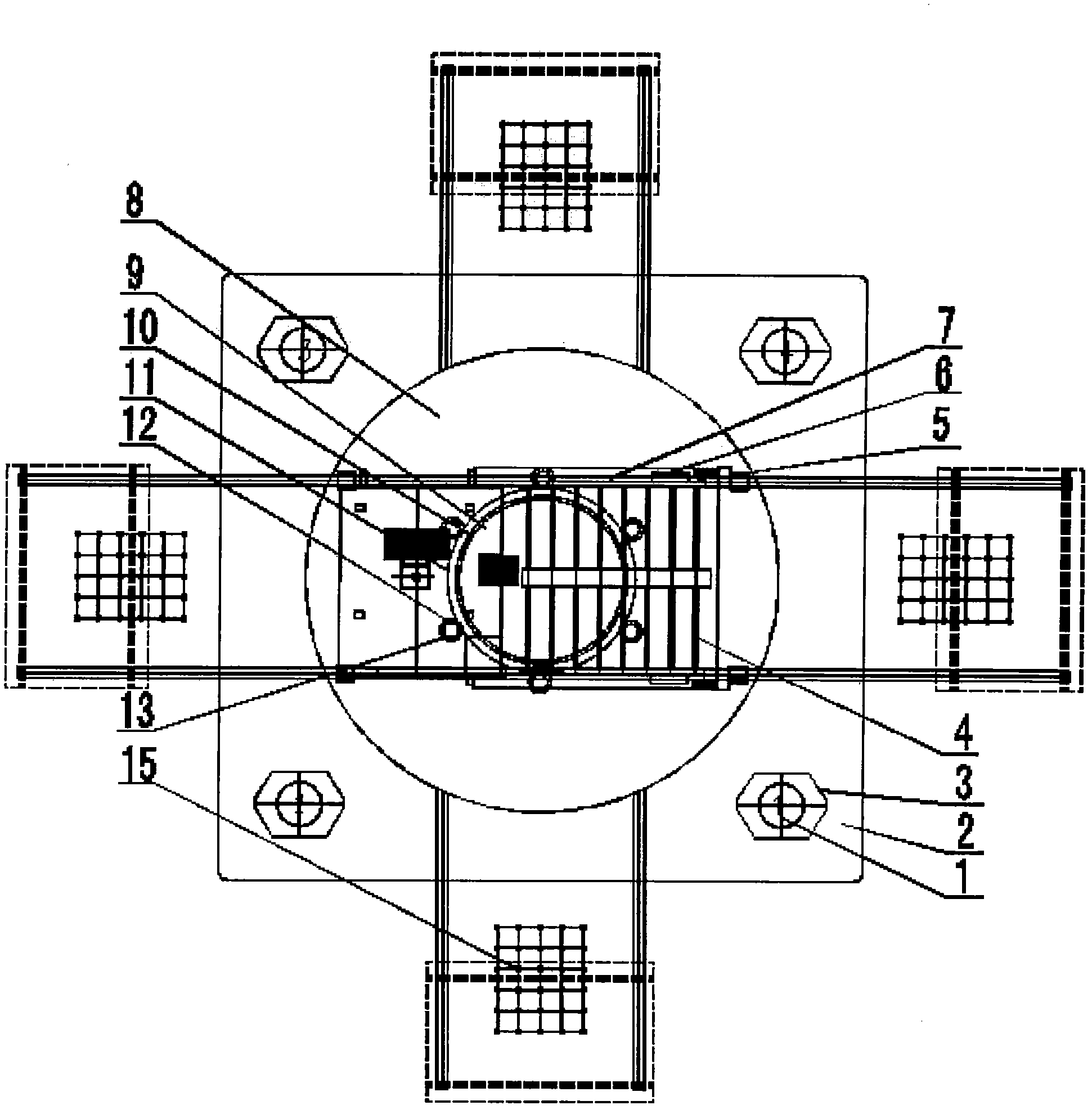

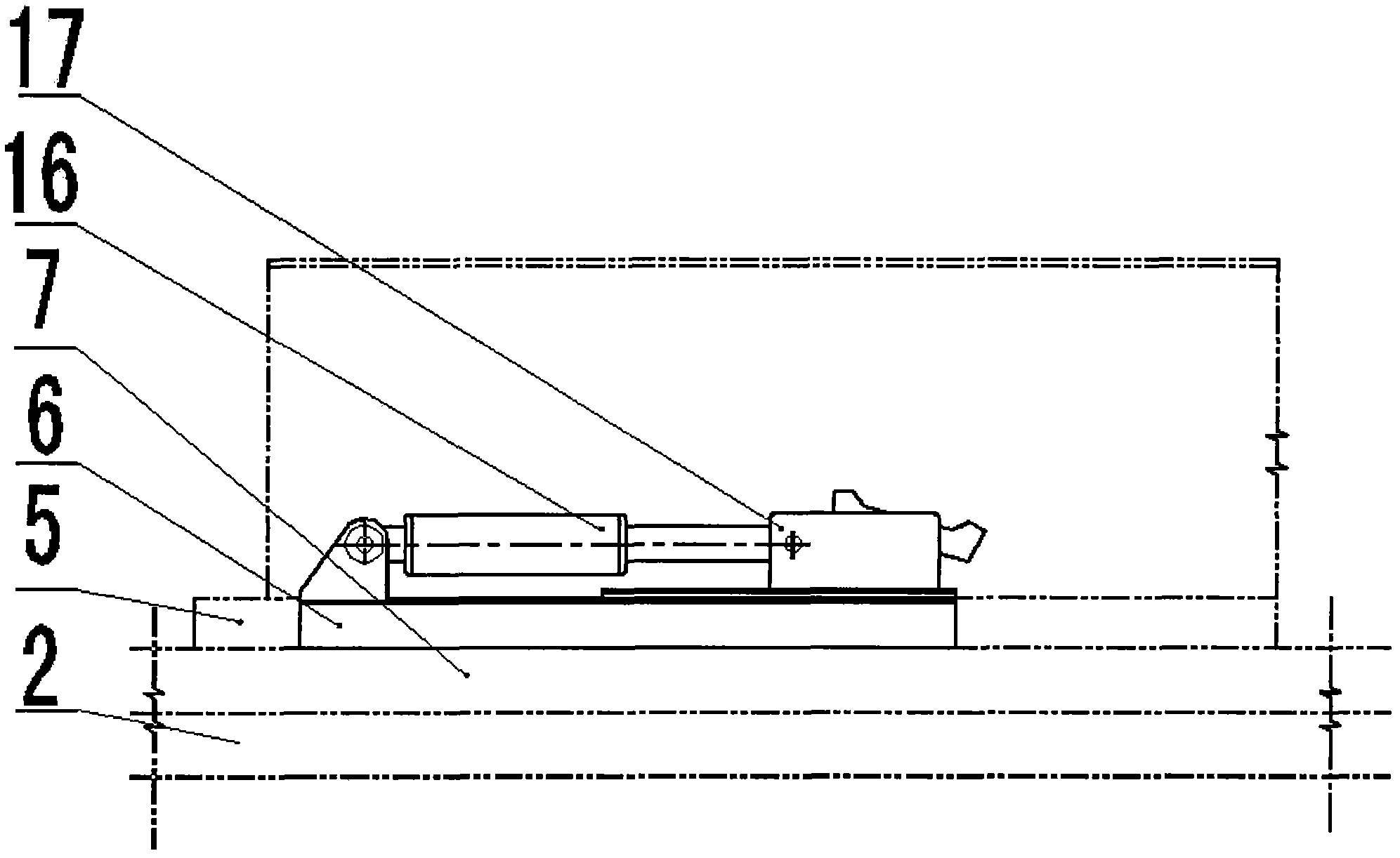

[0017] Now combined with the manual figure 1 , 2,3,4 further describe the present invention: mobile base 5, mobile device 6, mobile support track 7, reversing turntable 8, main shaft 9, rotating shaft 10, drive motor 13 constitute.

[0018] The main body 2 of the jack-up platform lowers the legs 1 to the seabed by means of the lifting device 3. After the platform is in place at sea, the drilling module 4 can move to the required position on the mobile support rail 7 through the moving device 6 and extend the jack-up platform. The cluster well group 15 is drilled outside the main body 2 of the platform. When the well position in one direction is completed, the drilling module 4 is reversely pushed by the mobile device 6 to the reversing turntable 8 and fixed, and the driving motor 13 drives the driving gear 12. Drive the ring gear 11 welded on the rotating shaft 10 to turn the reversing turntable 8 to another working position. During the rotation process, the annular centering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com