Multi-break plastic-shell type circuit breaker

A plastic case type, circuit breaker technology, applied in circuit breaker parts, circuit breaker contacts, circuits, etc., can solve the problems of increased heat accumulation, affecting the long-time delay action characteristics of long-time delay releases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

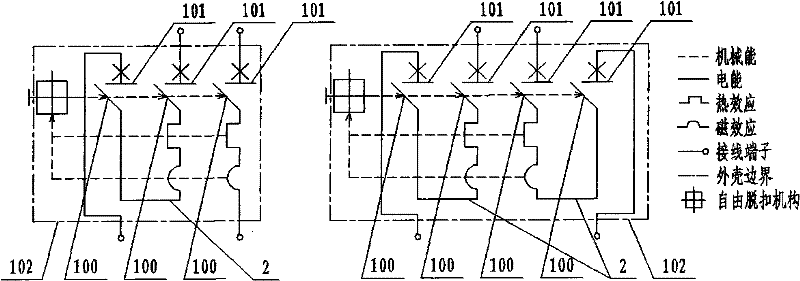

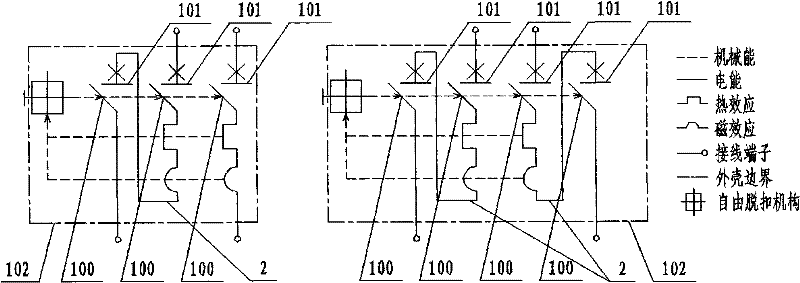

[0021] Embodiment 1 of the present invention, such as figure 1 shown. Inside the insulating case 102, it includes an operating mechanism, a trip lever, a moving contact set 100, a static contact 101, an arc extinguishing chamber, and an insulating rotating shaft. Two adjacent moving contact groups 100 are connected through conductors 2 . The outlet end of the circuit breaker is drawn out from the static contact.

[0022] Embodiment 2 of the present invention, such as figure 2 shown. Inside the insulating case 102, it includes an operating mechanism, a trip lever, a moving contact set 100, a static contact 101, an arc extinguishing chamber, and an insulating rotating shaft. A moving contact group 100 is connected to the corresponding static contacts 101 of the adjacent moving contact group 100 through the conductor 2 . The outlet end of the circuit breaker is drawn out from the moving contact group 100 .

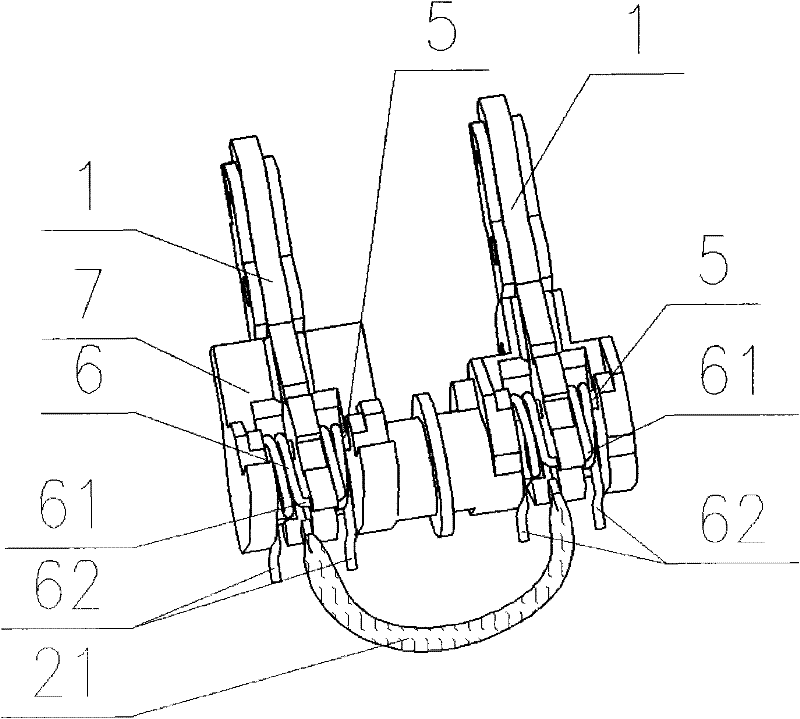

[0023] Embodiment 1.1 of the present invention, as Figure 3-5 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com