Width adjustment devices for conveyor aisles

A width adjustment, conveyor technology, applied in the direction of conveyors, mechanical equipment, conveyor objects, etc., can solve problems affecting reliability and accuracy, and achieve the effects of minimizing the chance of operating errors, simple use, and reduced wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

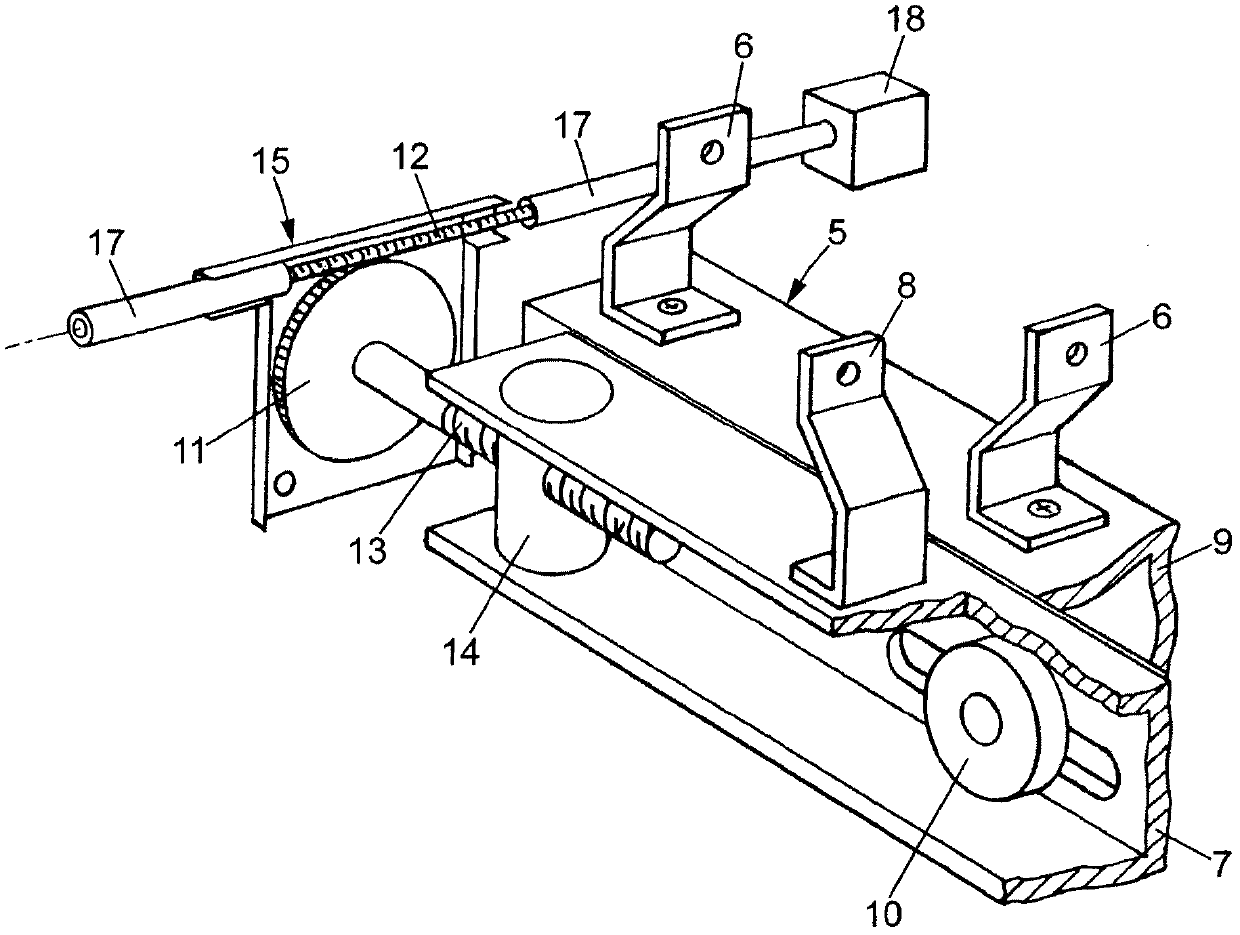

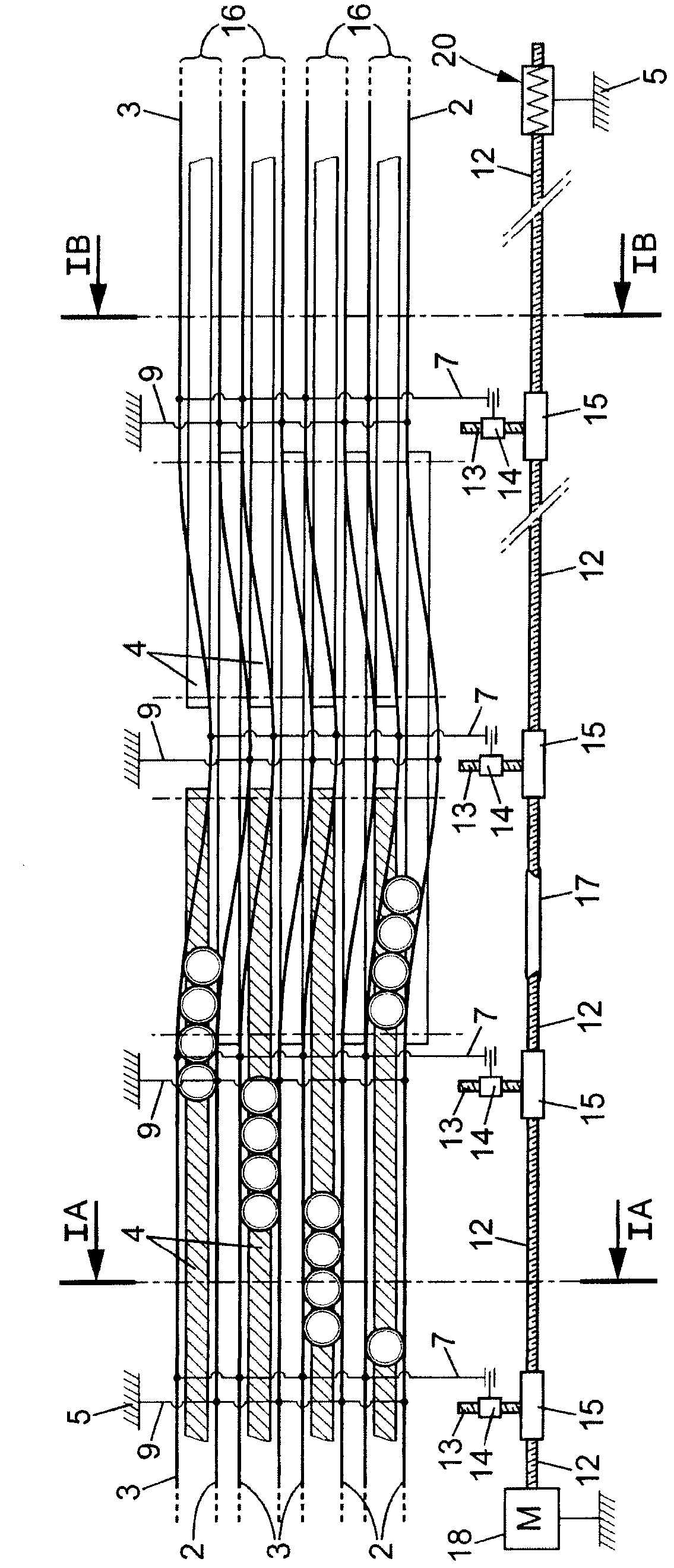

[0057] Structurally and operationally identical elements are denoted by the same reference numerals or letter designations in different drawings.

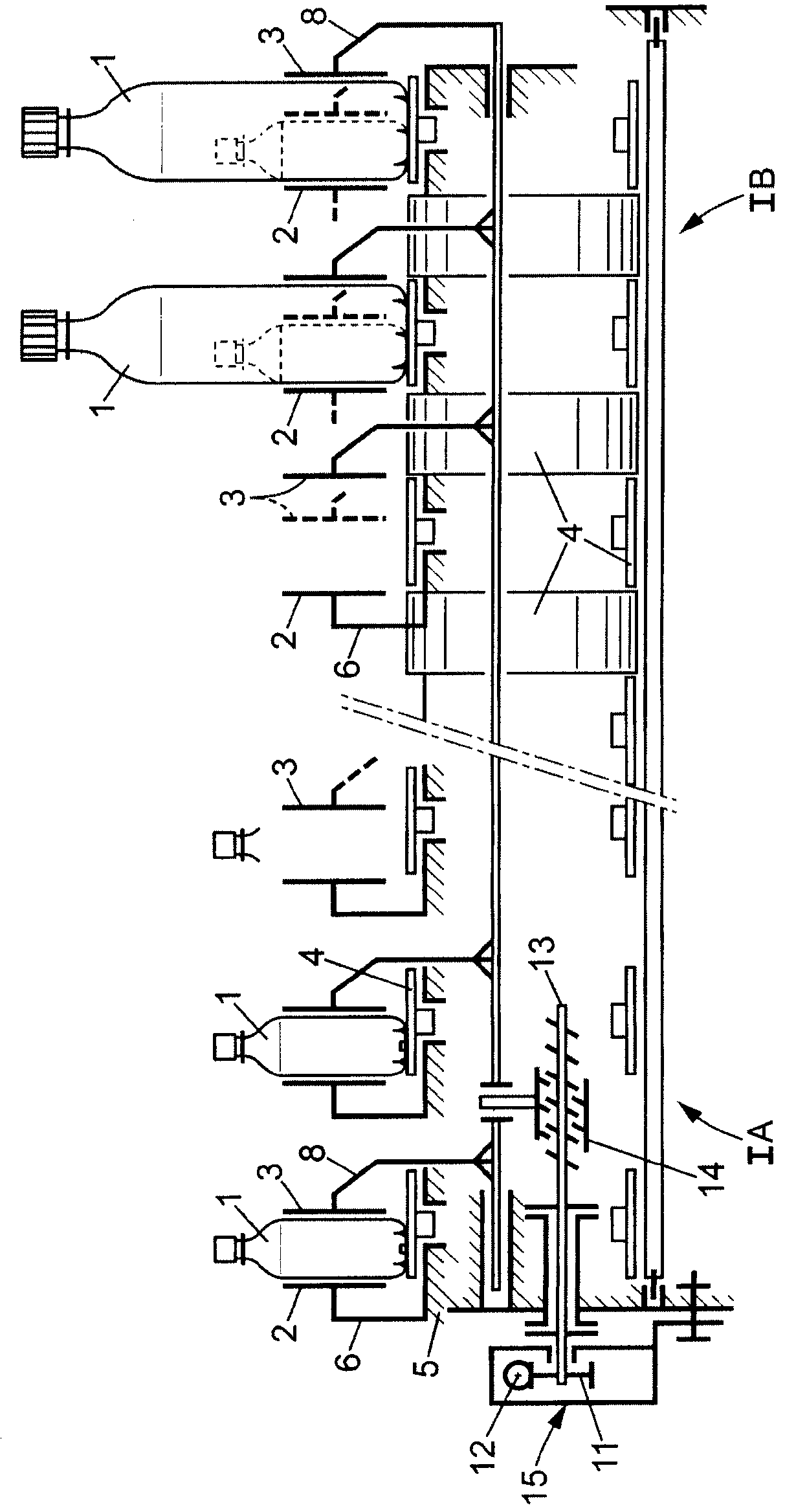

[0058] figure 1 The system of the invention is shown, which is designed for conveying bottles 1 . The system includes several linear corridors. Should figure 1 Section AA in Fig. 1 shows the small bottle 1 being guided, while section BB shows the large bottle 1 being guided.

[0059] Each corridor comprises two guide walls 2 and 3 or guide rails, said walls being arranged towards each other over the drive belt 4 .

[0060] exist figure 1 In the exemplary embodiment in , the walls 2 are fixed and the walls 3 are movable, which means that they can be adjusted by the adjustment device of the invention as detailed below.

[0061] Thus, the distance between the walls 2 and 23 of the corridor can be adapted to different diameters of bottles 1 .

[0062] The fixed walls 2 of the different corridors are supported by the underframe 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com