Installation structure for clip and attachment member

A technology for assembling structures and installing components, which is applied in the direction of connecting components, threaded fasteners, thin plate connections, etc., can solve the problems of difficult alignment of legs and corresponding mounting holes, deterioration of assembly efficiency, etc., and achieve the effect of improving clip insertion operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

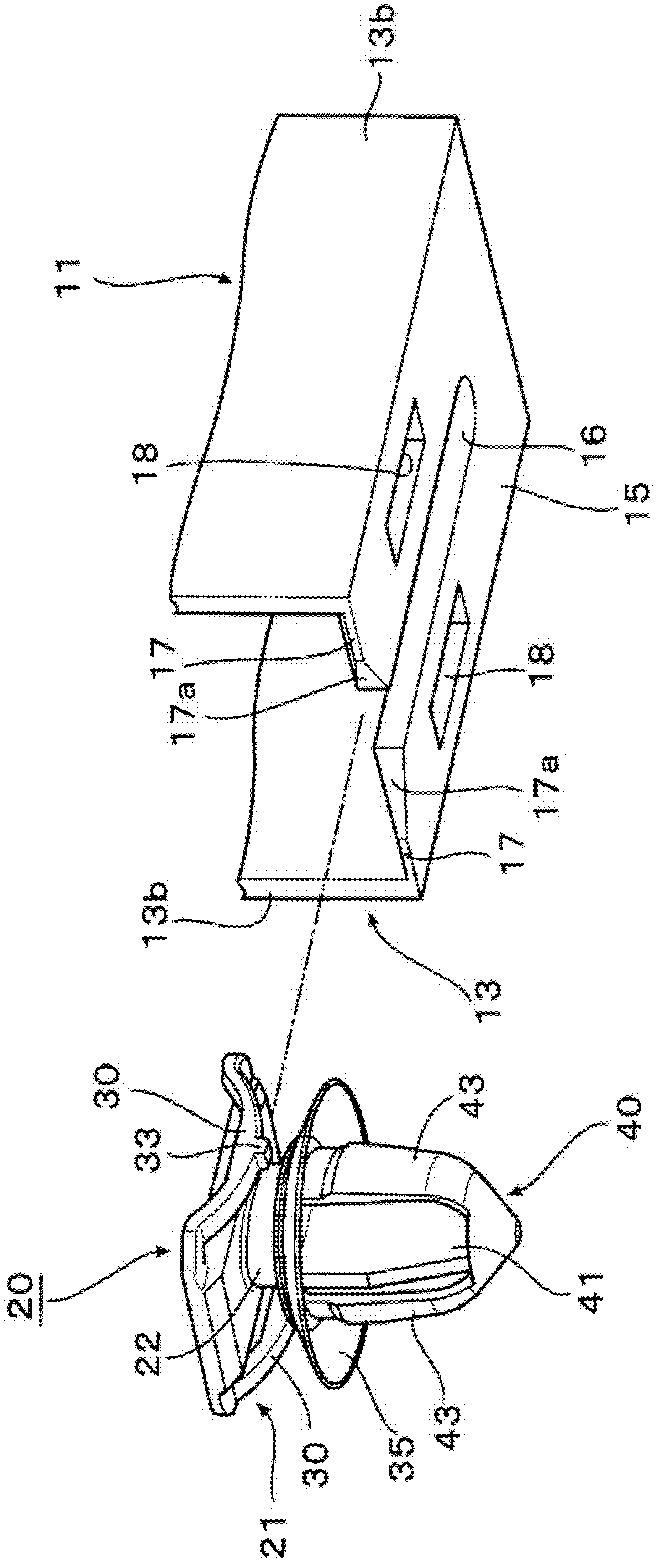

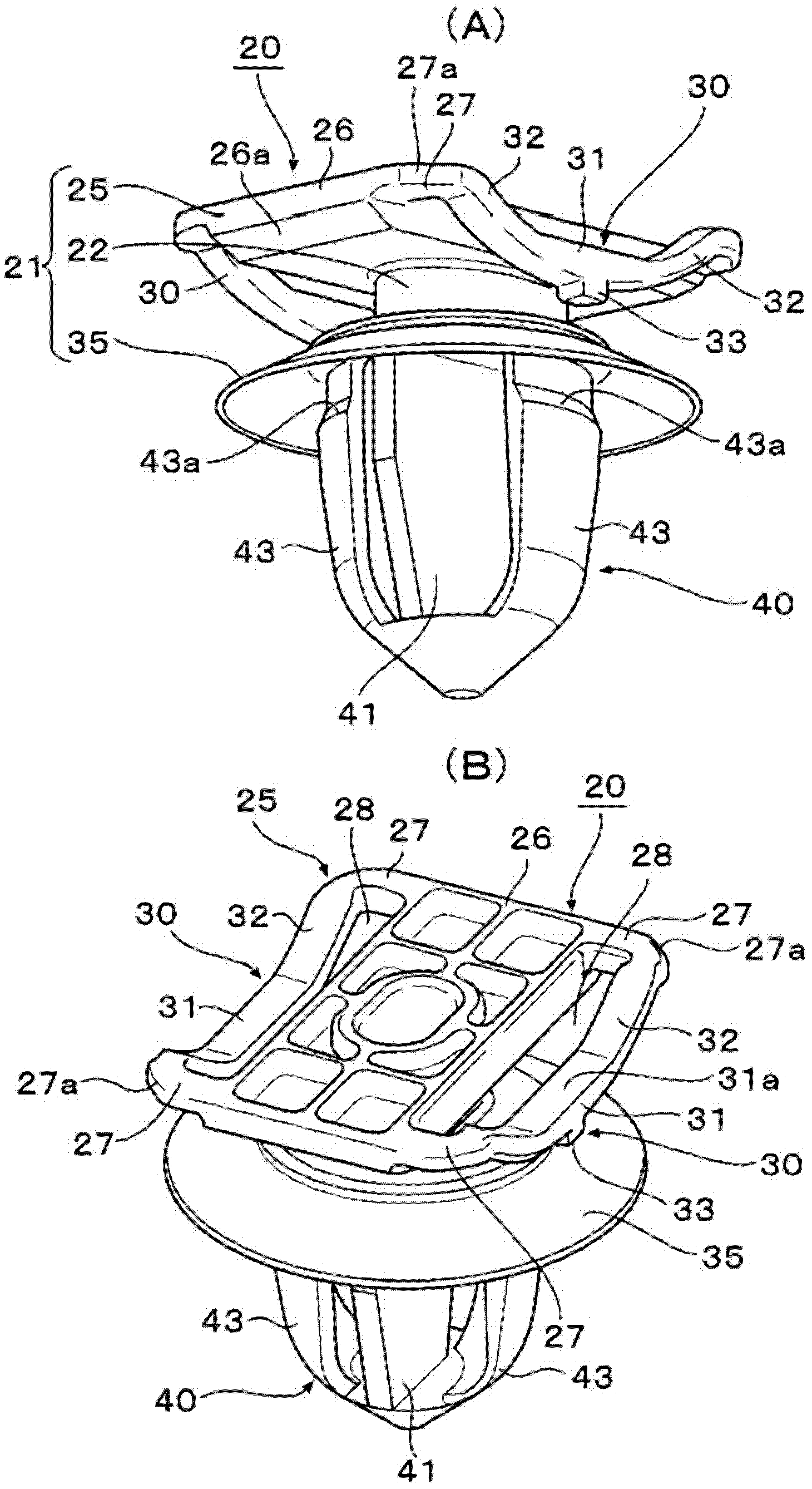

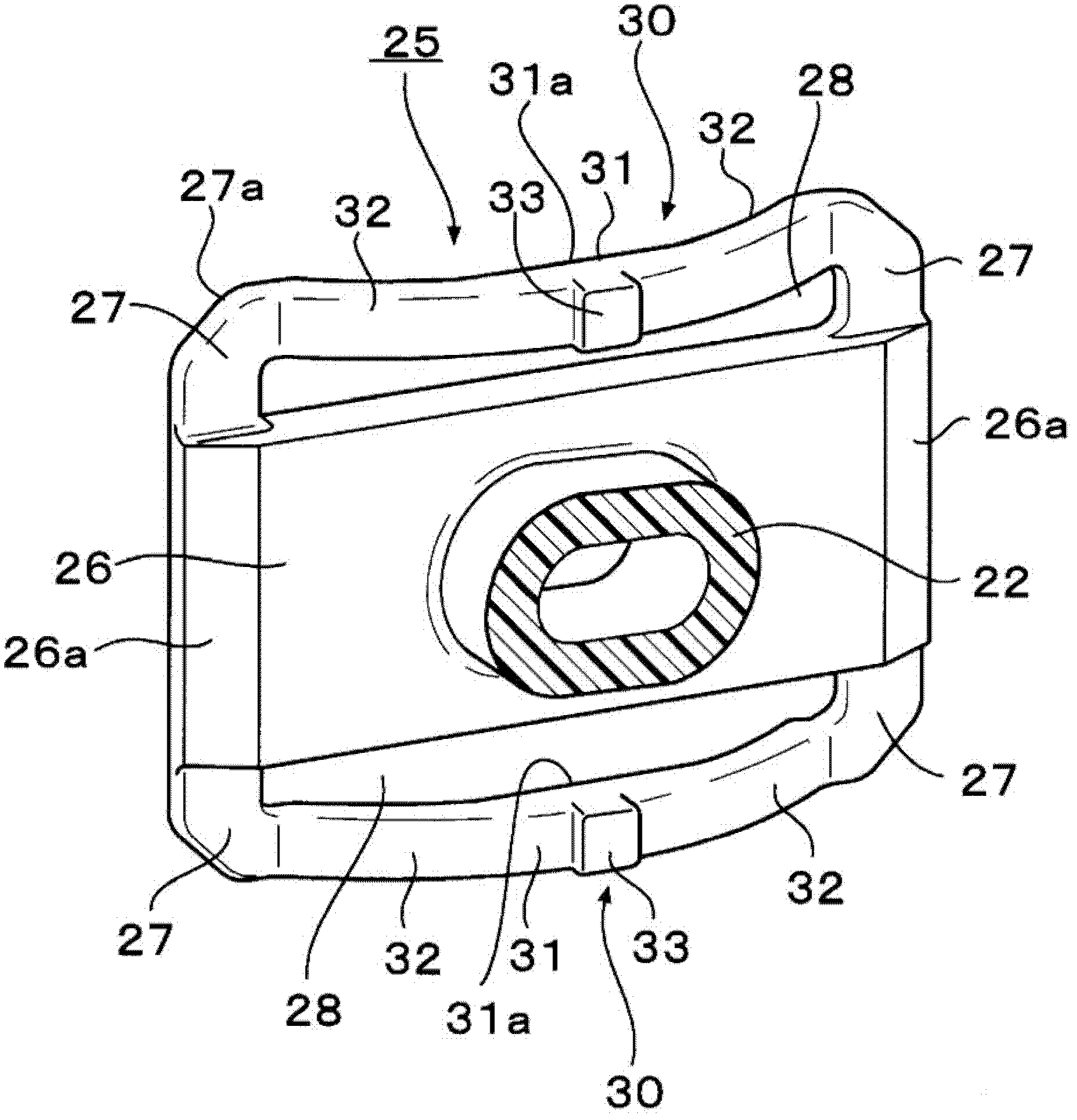

[0035] Such as Figure 8 As shown, for example, a clip 20 is used to mount a mountable part 10 such as an ornament or a trim panel to a supporting part 1 such as a motor vehicle body panel, and the clip 20 has a head 21 and a leg 40 . The head 21 is inserted into the plate-shaped mounting seat 15 formed on the mountable part 10 to be assembled, and the leg part 40 is inserted into the mounting hole 5 formed in the supporting part 1 to be engaged therewith, thereby, via The clip 20 mounts the mountable part 10 on the supporting part 1 .

[0036] In the following, refer to Figure 1 to Figure 8 , describing an embodiment of the assembly structure of the clip and the mountable part according to the present invention.

[0037] First, see figure 1 ,as well as Figure 4 to Figure 8 , describing the structure of the installable part 10. In the present embodiment, a plurality of base frames 11 each having a plate-shaped mounting seat 15 are provided on the rear side of the mounta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com