Work fixture for measuring light transmittance of optical filter

A tooling fixture and optical filter technology, which is applied in the field of lighting, can solve the problems of large differences in results, inability to accurately test the true transmittance of optical filters, and low measurement accuracy, so as to achieve accurate measurement, save manpower, and improve measurement efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

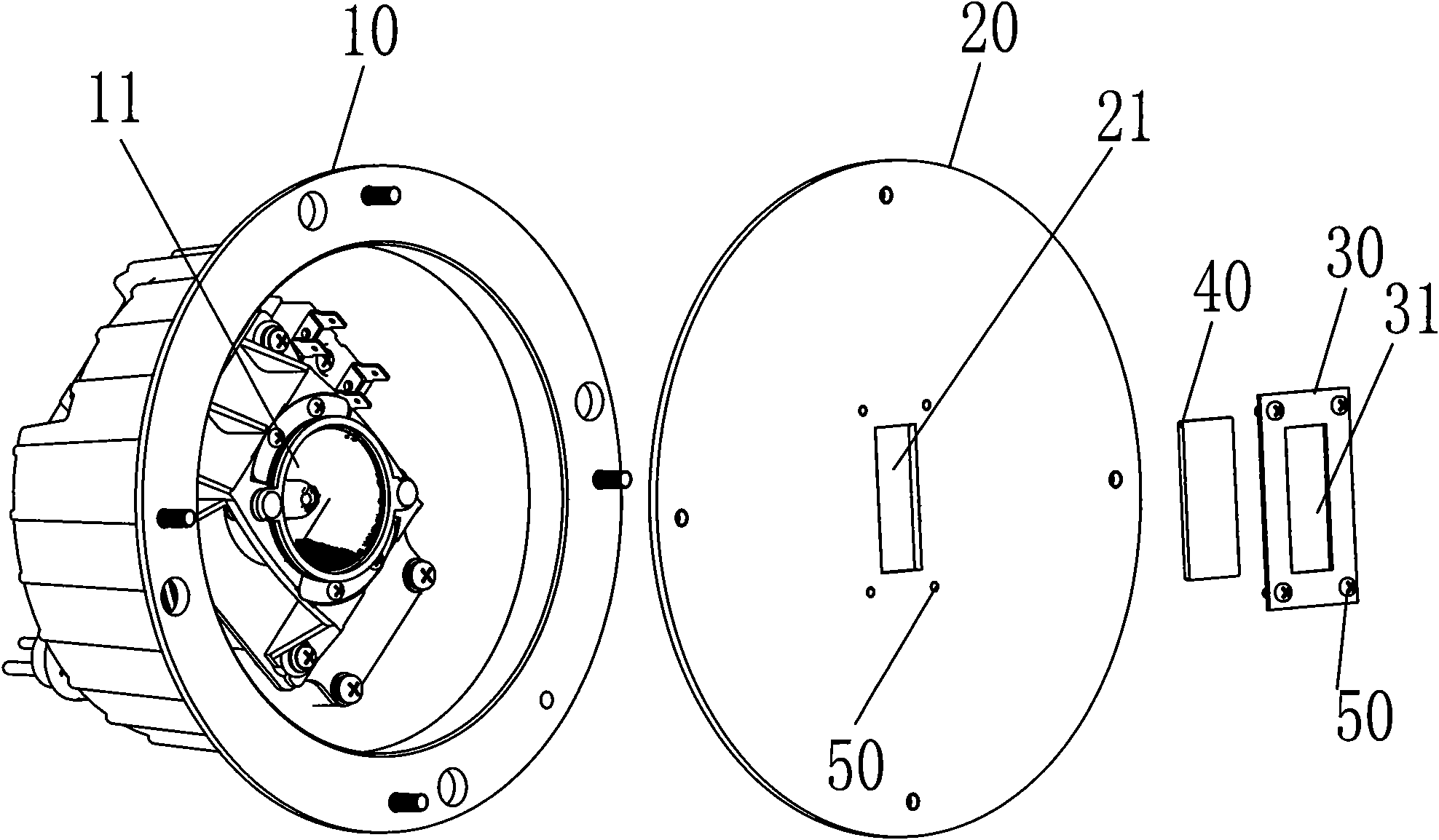

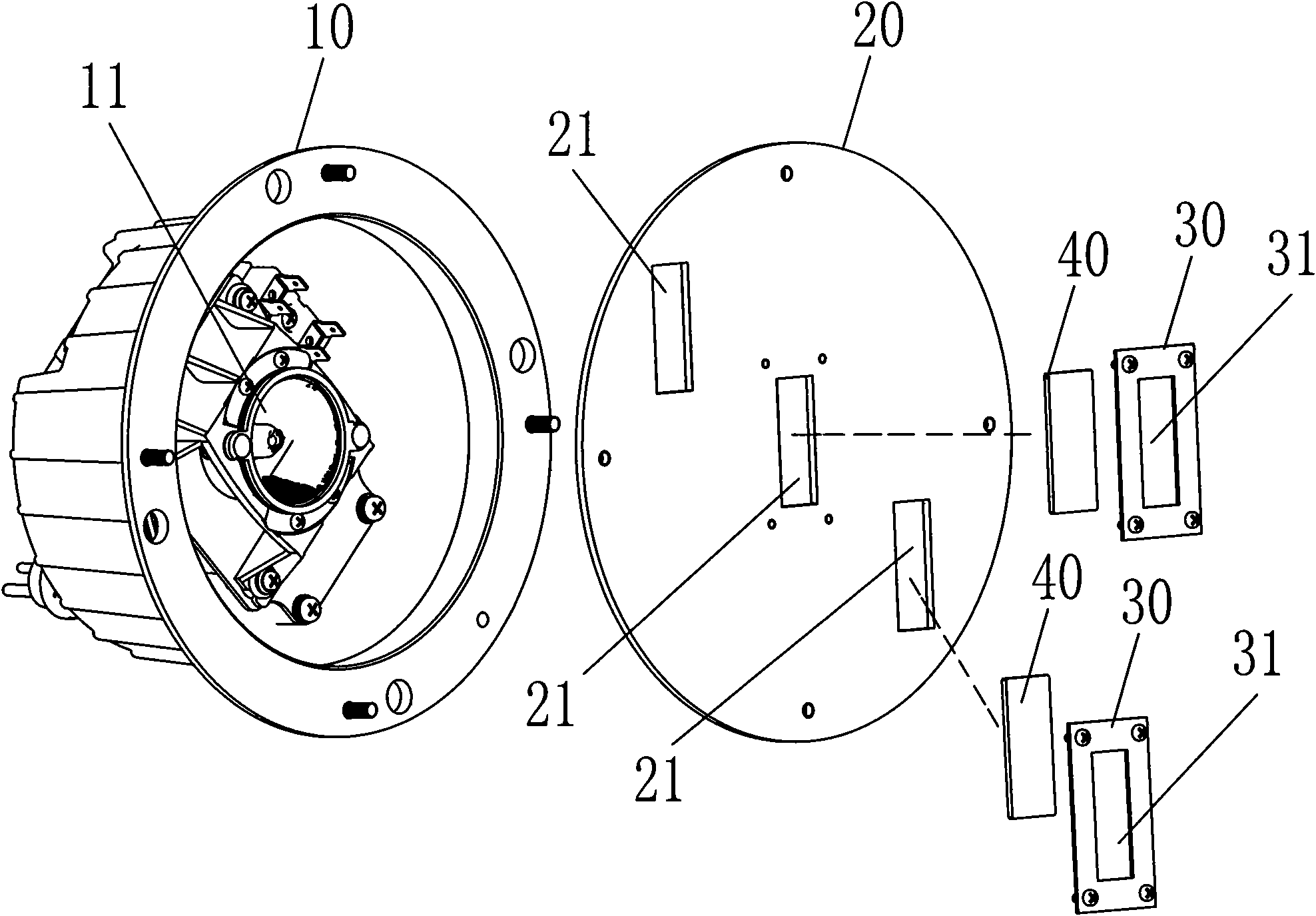

[0020] The structure of the fixture for measuring the light transmittance of the optical filter in the preferred embodiment of the present invention is as follows: figure 1 As shown, it includes a base 10 with a recess, a light source 11 is arranged in the recess of the base 10, a mounting plate 20 is provided at the opening of the base 10, and the mounting plate 20 is detachably connected to the opening of the base 10 by screws around it, and The mounting plate 20 is provided with a first light-transmitting hole 21 to transmit light. A pressing sheet 30 for fixing the optical filter 40 to the first light transmission hole 21 is also arranged on the mounting plate 20, and a second light transmission hole 31 for facilitating the light transmission of the optical filter 40 is arranged on the pressing sheet 30, In this way, the light emitted from the light source 11 passes through the first light transmission hole 21 , the filter 40 and the second light transmission hole 31 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com