Processing additive, molding composition, masterbatch of processing additive and molding article

A technology of processing aids and compositions, which is applied in the field of molding compositions and processing aids, can solve the problems of low dispersion of fluoropolymers, die accumulation, etc. The effect of shortening the melt fracture elimination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

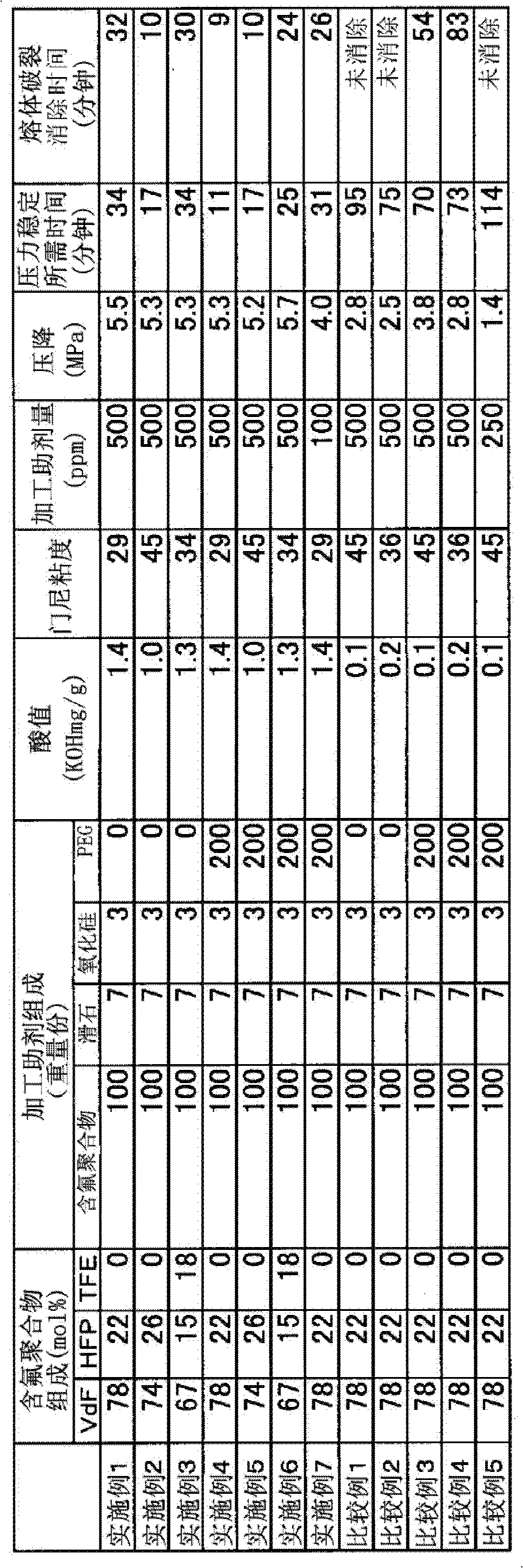

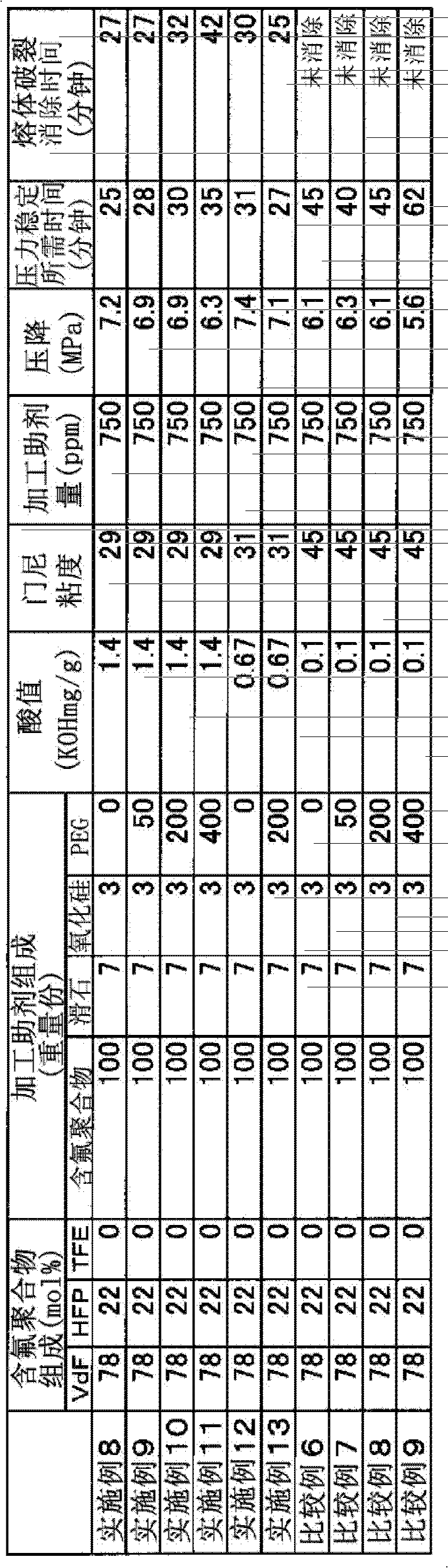

Embodiment 1~13 and comparative example 1~9

[0111] (manufacturing of processing aids)

[0112] Each fluoropolymer was pulverized using a pulverizer (manufactured by Kawata Corporation, Rapid R-1528), and 7 parts by weight of talc (manufactured by Nippon Talc Co., Ltd., P-2) and 3 parts by weight were added to 100 parts by weight of the fluoropolymer. Parts of silicon oxide (manufactured by GRACE, SYLOBLOC 45H) were mixed with a small pulverizer (Millser 300DG, manufactured by Iwatani Sangyo Co., Ltd.) to produce a processing aid.

[0113] In the case of Examples 4 to 7, 9 to 11, and 13 and Comparative Examples 3 to 5, and 7 to 9, a predetermined amount of polyethylene glycol (manufactured by DOW CHEMICAL, CARBOWAX TM SENTRY TM POLYETHYLEN GRYCOL 8000 GRANULAR NF, hereinafter "PEG". ), by tumbling to manufacture processing aids containing PEG.

[0114] (manufacturing of masterbatch)

[0115] Thereafter, in linear low-density polyethylene (manufactured by EXXON MOBIL, LLDPE 1002YB), the above-mentioned processing ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com