Cover glass for flat panel displays

A technology for flat panel display and protective glass, which is applied in glass forming, glass tempering, glass forming, etc. It can solve the problems of strength reduction and achieve the effects of suppressing the generation of defects, preventing spontaneous damage, and reducing the production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Hereinafter, the present invention will be described with reference to Examples, but the present invention is not limited to these Examples.

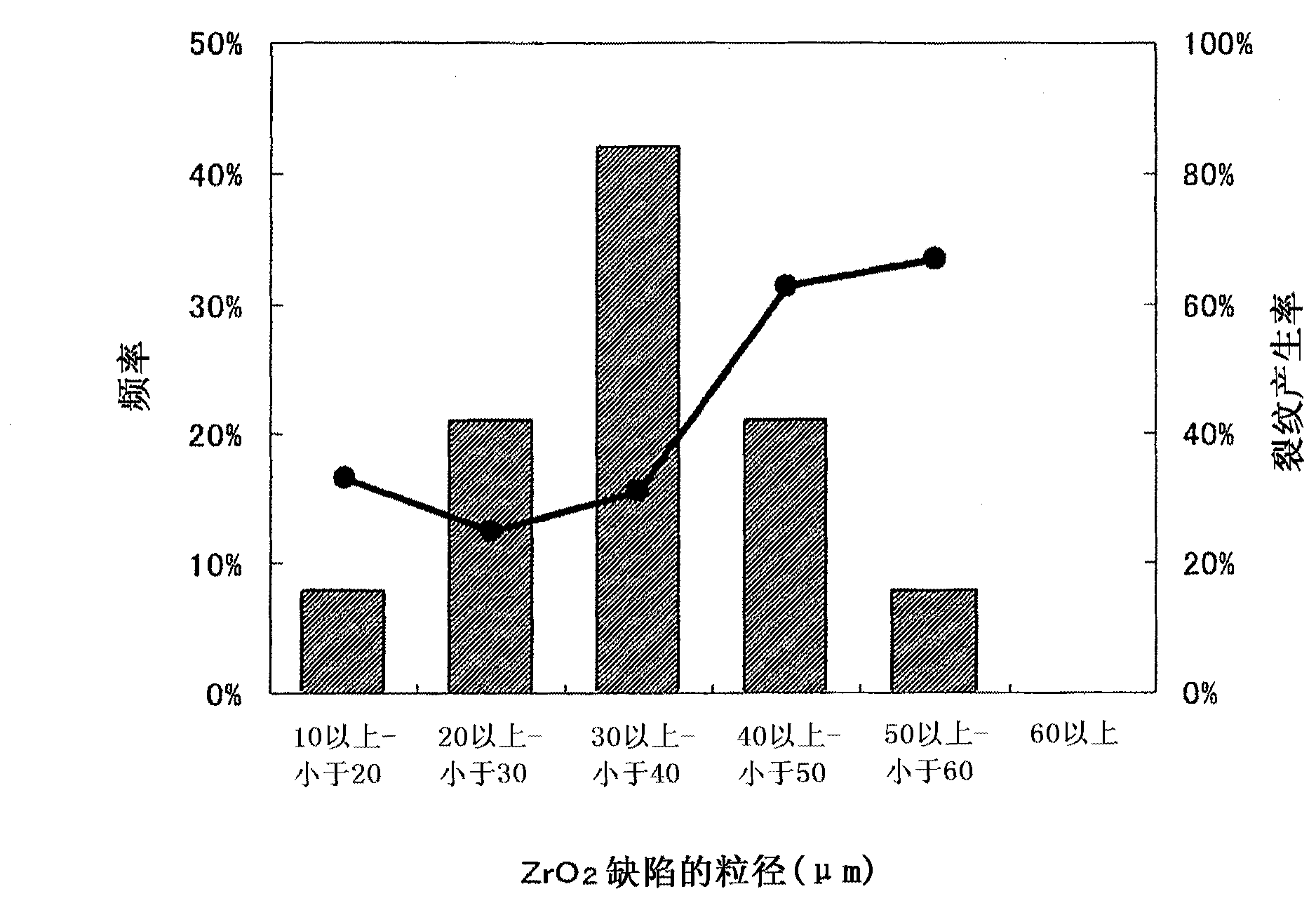

[0101] Glass manufactured by the fusion method [composition (mol %): SiO] was measured using optical microscope photographs of 38 samples 2 66.6%, Al 2 O 3 10.8%, Na 2 O 13.2%, K 2 The particle size (diameter) of defects in O 2.4%, MgO 6.2%, CaO 0.6%], and the frequency in each particle size range was calculated. The particle size of the defect was determined by comparing the length of the largest portion with the photograph of the objective micrometer. The results are shown in figure 1 bar chart.

[0102] Moreover, the generation rate of cracks in the said glass was measured. Here, the occurrence rate of cracks is measured by visually determining whether or not cracks have occurred in the micrograph. The results are shown in figure 1 line chart.

[0103] like figure 1 As shown in the line graph of , when the particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com