Semiconductor engineering recording equipment

A technology for recording equipment and semiconductors, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as overheating burnout, radiation plate burnout, endpoint device component damage, etc., and achieve the effect of reducing production costs and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The aforementioned and other objects, features, and advantages of the present invention will be more apparent with reference to the following detailed description and accompanying drawings. Preferred embodiments according to the present invention will be described in detail with reference to the drawings.

[0029] Example.

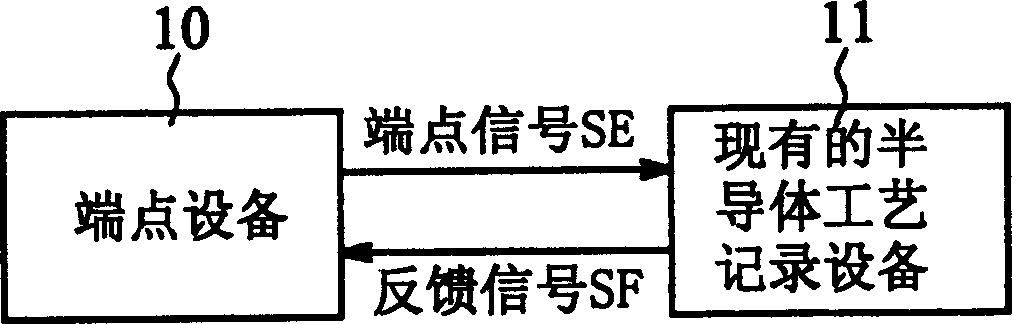

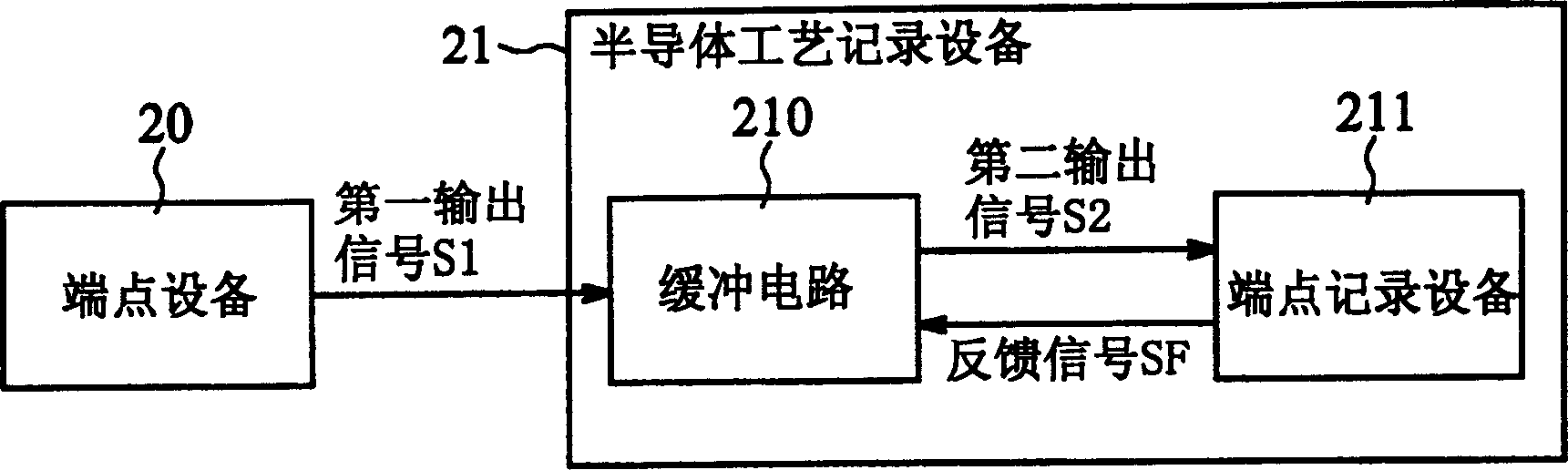

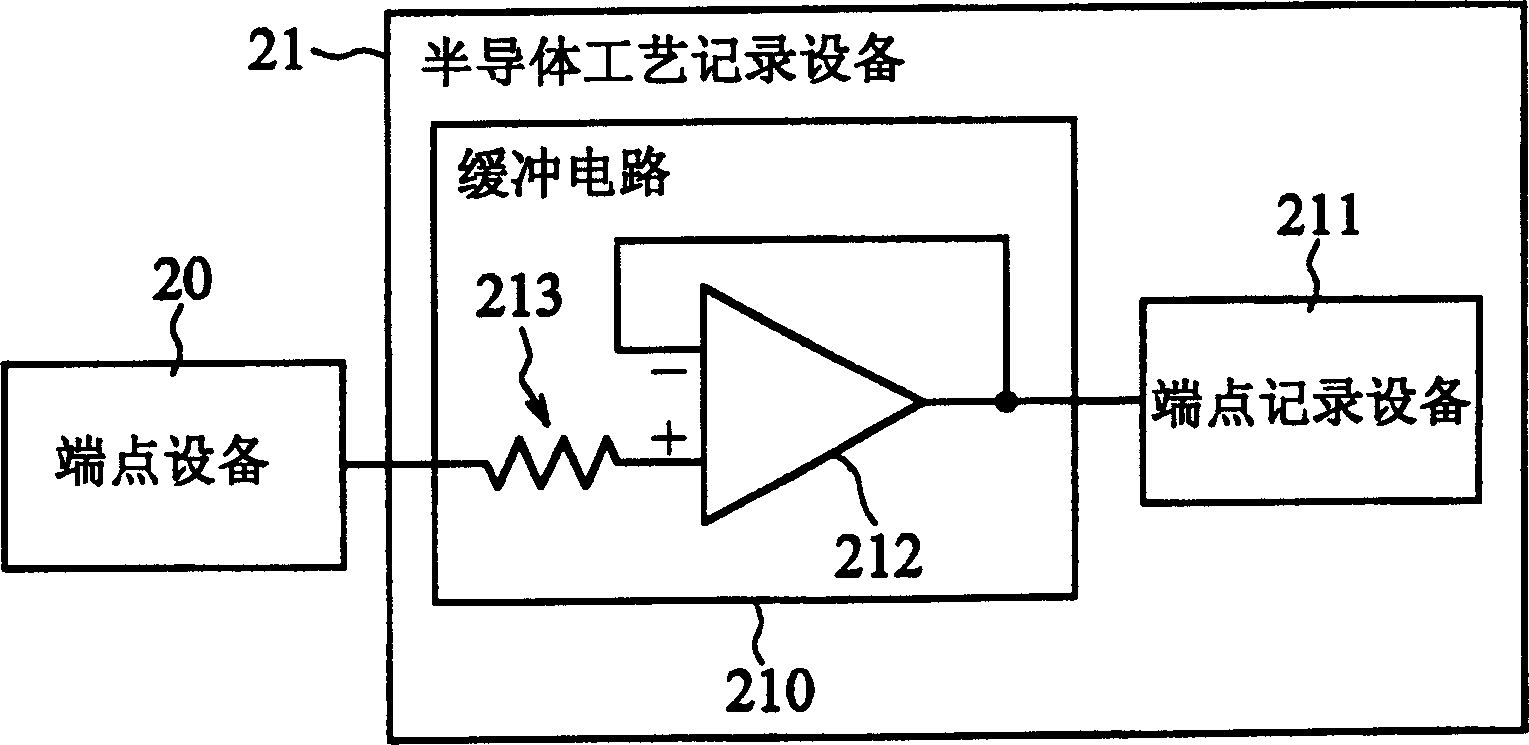

[0030] Figure 2A is a circuit block diagram showing a semiconductor process recording apparatus according to a first embodiment of the present invention. Such as Figure 2A As shown, the semiconductor process recording equipment 21 according to the first embodiment of the present invention includes a buffer circuit 210 and an endpoint recording device 211 . The endpoint recording device 211 according to the present invention may be as figure 1 Existing semiconductor process recording equipment 11 or the like is shown. The semiconductor process recording device 21 is connected to an external endpoint device 20 for recording the working status o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com