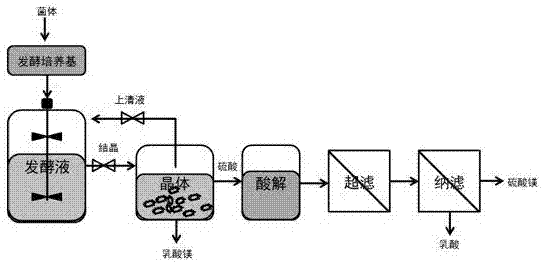

A kind of fermentation-separation coupling prepares the method for lactic acid and/or lactate

A technology of lactic acid and magnesium lactate, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid compounds, etc., can solve problems such as low yield and long lactic acid cycle, and achieve cost reduction, pollution reduction, Good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 2L of defatted rice bran hydrolyzate is used as a medium, 15g / L rice bran protein hydrolyzate is used as a nitrogen source, inoculated with 10% Lactobacillus rhamnosus, the temperature is 42°C, the speed is 280rpm, 20% magnesium oxide is used as a neutralizer, and the pH is controlled at 6.2- 6.25 After a fermentation period of 60 hours, a magnesium salt fermentation liquid with a lactic acid content of 156 g / L was obtained. The first batch of fermented liquid was left to settle at room temperature for 2 hours, and the crystallization rate of magnesium lactate was 50%, and the supernatant was returned to the fermenter for the second batch of fermentation; the lactic acid content of the second batch of fermented liquid reached 140g / L, and the crystallization rate was 48%; The third batch of fermentation reached 140g / L, and the crystallization rate was 47%; this cycle continued until the productivity decreased significantly.

[0034] Magnesium lactate crystals were washed...

Embodiment 2

[0036] Magnesium salt fermented liquid as described in embodiment 1.

[0037] Magnesium lactate crystals were washed with water at 4°C to remove soluble impurities to obtain crude magnesium lactate; redissolved in distilled water to 100g / L, removed impurities with an ultrafiltration membrane with a molecular weight cut-off of 6KDa, evaporated and recrystallized at 70°C and 0.09MPa , The crystals were dried at 0.9MPa, 50°C for 3h, and the finished product of magnesium lactate with a purity of 96% was obtained. The recrystallization supernatant was adjusted to pH 2.5 with sulfuric acid; the acid hydrolysis feed solution was decolorized and impurity-removed with an ultrafiltration membrane with a molecular weight cut-off of 3KDa; the ultrafiltration feed solution was removed with Dow NF270 at 1.0 MPa and 40°C to remove multivalent ions and small molecular impurities ; The nanofiltration permeate liquid is concentrated at 70°C into a finished product of lactic acid with a purity o...

Embodiment 3

[0039] Magnesium salt fermented liquid as described in embodiment 1.

[0040]Magnesium lactate crystals were washed with water at 0°C to remove soluble impurities to obtain crude magnesium lactate; redissolved in distilled water to 60g / L; adjusted to pH 2.3 with sulfuric acid; impurity was removed by an ultrafiltration membrane with a molecular weight cut-off of 3KDa; Use Dow NF270 at 0.8 MPa and 50°C to remove multivalent ions and small molecular impurities; the nanofiltration permeate liquid is concentrated at 70°C to produce lactic acid with a purity of 85%. Magnesium sulfate in the nanofiltration retentate is crystallized to obtain magnesium sulfate with a purity of 96%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com