Liquid fabric conditioner composition and method of use

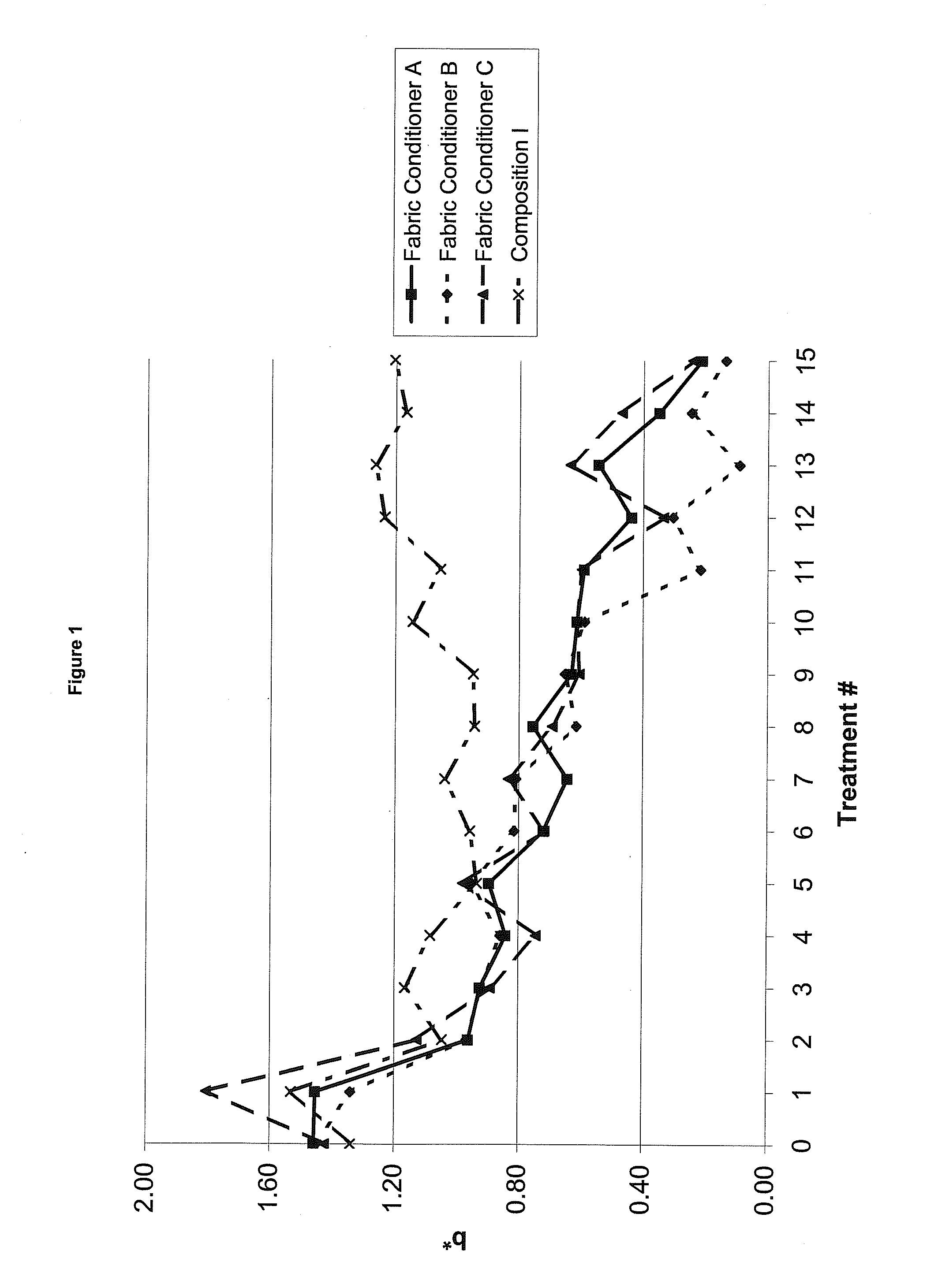

a liquid fabric conditioner and composition technology, applied in the preparation of detergent mixture compositions, detergent compounding agents, dry-cleaning apparatus for textiles, etc., can solve the problems of excessive fabric yellowing, inability to operate at elevated temperatures, and inability of residential dryers to achieve the effect of reducing the tendency to pick up and reducing discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0062]Unless otherwise stated, all wash and rinse procedures were run in a 35 pound Milnor washing machine using 5 grain water.

[0063]The Following Towels, Scouring Procedure and Wash / Rinse / Dry were Followed for the Low and High Alkaline Washes:

[0064]New white cotton terry towels, each having an approximate weight of 0.5 kg, purchased from Institutional Textiles were scoured to remove from the fabric any processing aids used during manufacturing. The scouring was done in a 35 lb. Milnor Washing Machine and was accomplished according to the following procedure.

[0065]Scouring Protocol

[0066]Step One:

[0067](a) A first low water level wash of about 12 gallons was undertaken for 20 minutes at 130 degrees Fahrenheit. 70 grams L2000XP detergent available from Ecolab of St. Paul, Minn. was used for the first low water level wash. The water was drained from the wash tub.

[0068](b) A second low water level wash of about 12 gallons was undertaken for 10 minutes at 120 degrees Fahrenheit using 70 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com