Preparation method of high-selectivity reverse osmosis membrane by covering membrane surface defects

A high-selectivity, reverse osmosis membrane technology, used in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of less attention to the secondary structure of the polyamide layer, unclear sources of polyamide membranes, and no research Reports and other issues to achieve the effect of inhibiting the generation of defects, improving selectivity, and inhibiting the formation of secondary structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

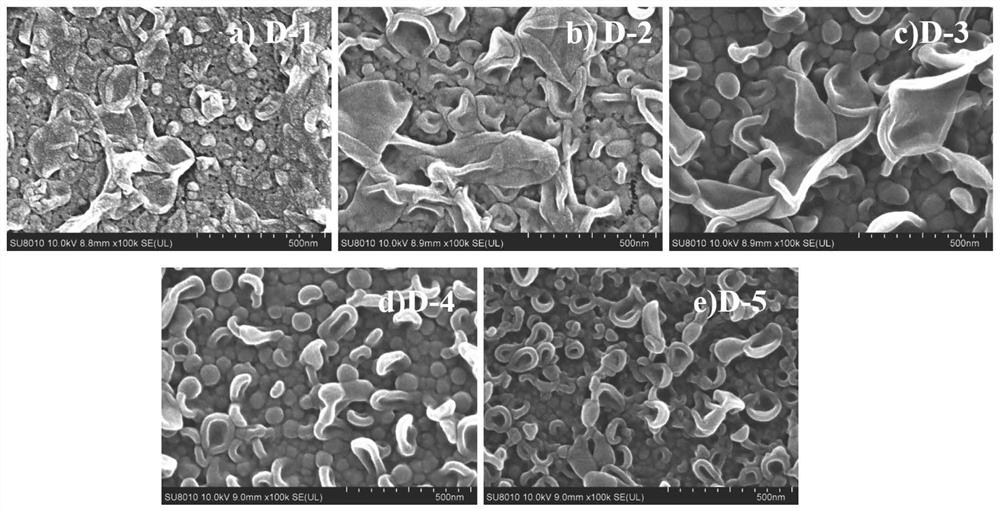

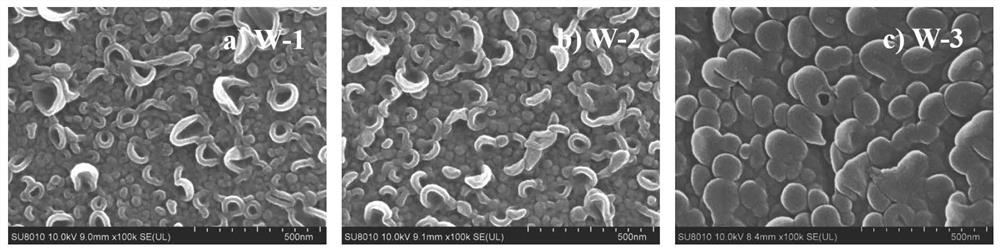

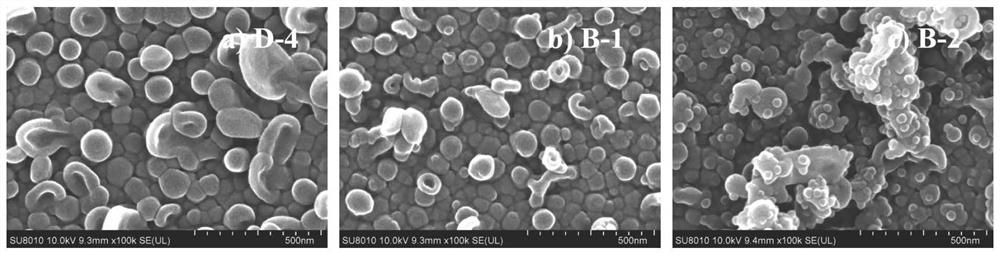

[0061] In order to prepare a high-selectivity composite membrane, the generation of surface defects on the polyamide membrane can be avoided by optimizing the monomer concentration formula, and the formation of the secondary structure on the membrane surface can be suppressed. The specific implementation cases are as follows:

[0062] 1. The preparation steps of the membrane were repeated in Comparative Example 1, the only difference being that "the concentration of trimesoyl chloride in the oil phase solution was replaced with 0.13wt%", and the rest of the steps were the same, and finally a composite reverse osmosis membrane was prepared. The number of this film is designated as M-1.

[0063] 2. The preparation steps of the membrane were repeated in Comparative Example 1, the only difference being that "the concentration of trimesoyl chloride in the oil phase solution was replaced by 0.16wt%", and the rest of the steps were the same, and finally a composite reverse osmosis me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com