U-shaped nail symmetric punching and positioning mechanism

A positioning mechanism and symmetrical technology, which is applied in the field of U-shaped nail symmetrical stamping positioning mechanism and the device for manufacturing U-shaped nails, can solve the problems of high and low feet, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

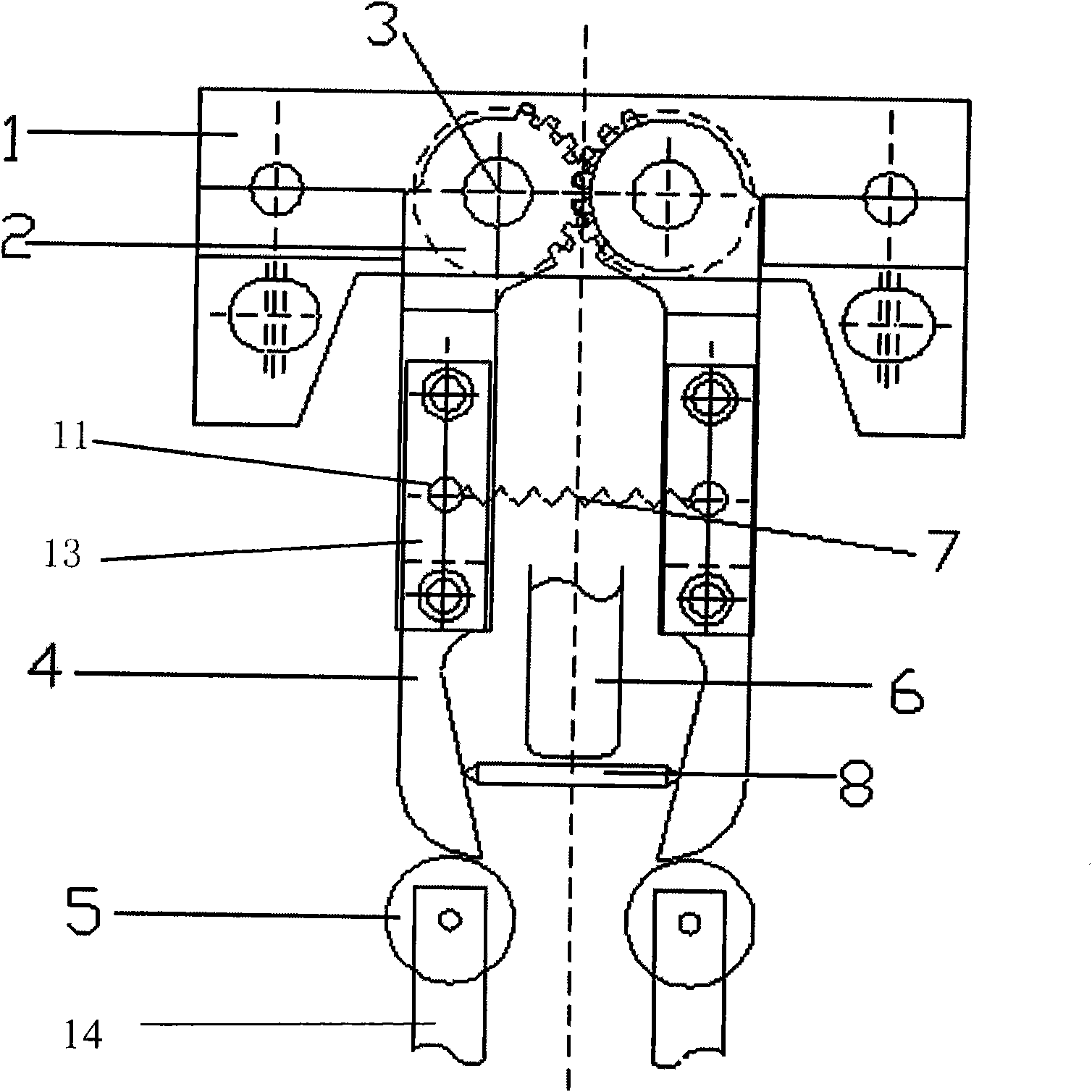

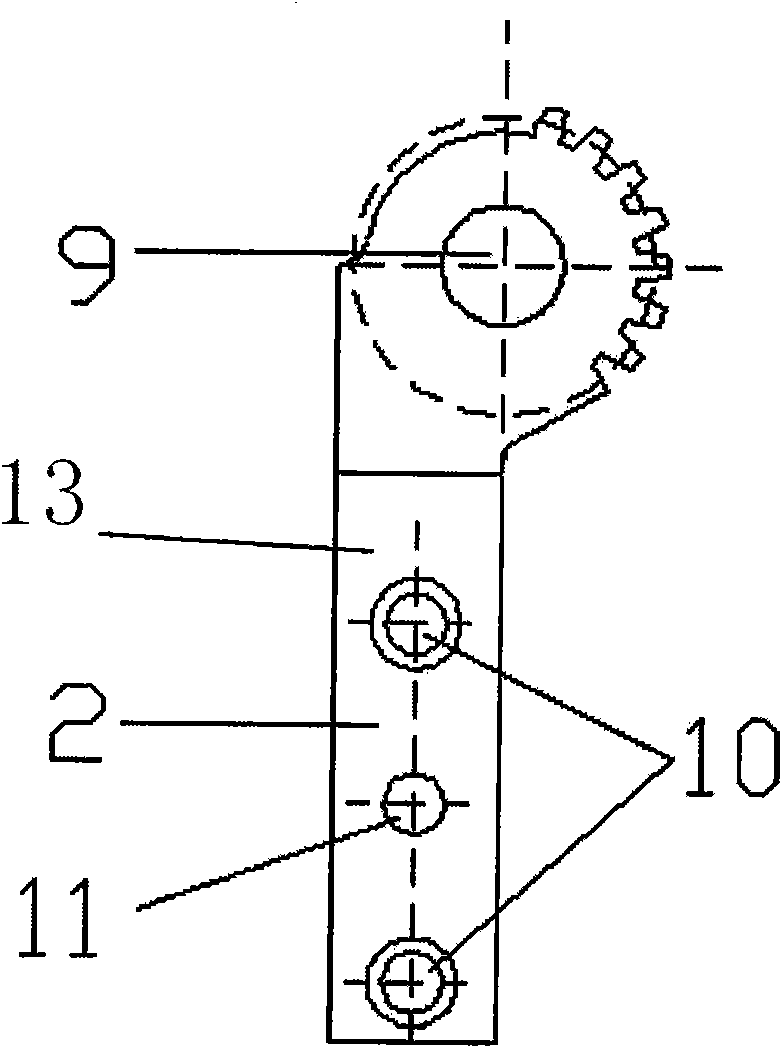

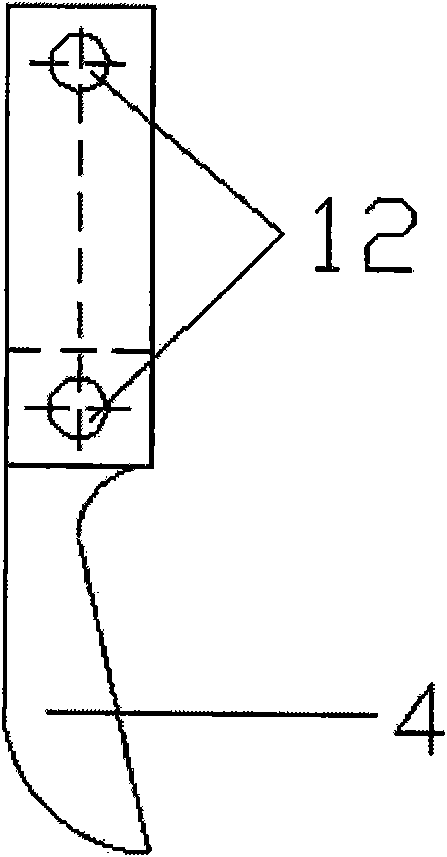

[0012] Such as figure 1 , figure 2 and image 3 As shown, a U-shaped nail symmetrical stamping positioning mechanism of the present invention is composed of a gear seat 1, wherein two positioning devices are symmetrically arranged in the gear seat 1, and any one of the positioning devices is respectively positioned by a Arm 13 and a support seat 14 constitute, and the upper end of any one described positioning arm 13 is all fixedly provided with a gear 2, and the described gear 2 of two positioning arms 13 upper ends meshes with each other, and the center of circle of any one gear 2 is Gear holes 9 are provided, and any one of the gear holes 9 is provided with a gear shaft 3, and any one of the gear shafts 3 is arranged in the gear seat 1, and the symmetrical positions of the positioning arms 13 in the two positioning devices A spring 7 is connected between them, and the lower end of any positioning arm 13 is provided with a fork 4, and the opposite sides of the fork 4 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com