Saw blade clamping device

A clamping device and saw blade technology, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problems of time-consuming, labor-intensive efficiency, low efficiency, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

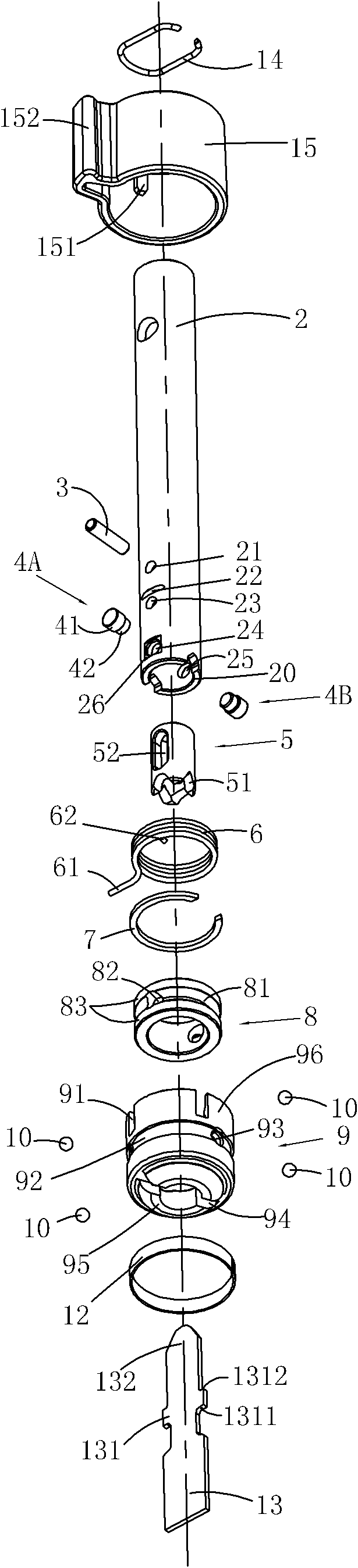

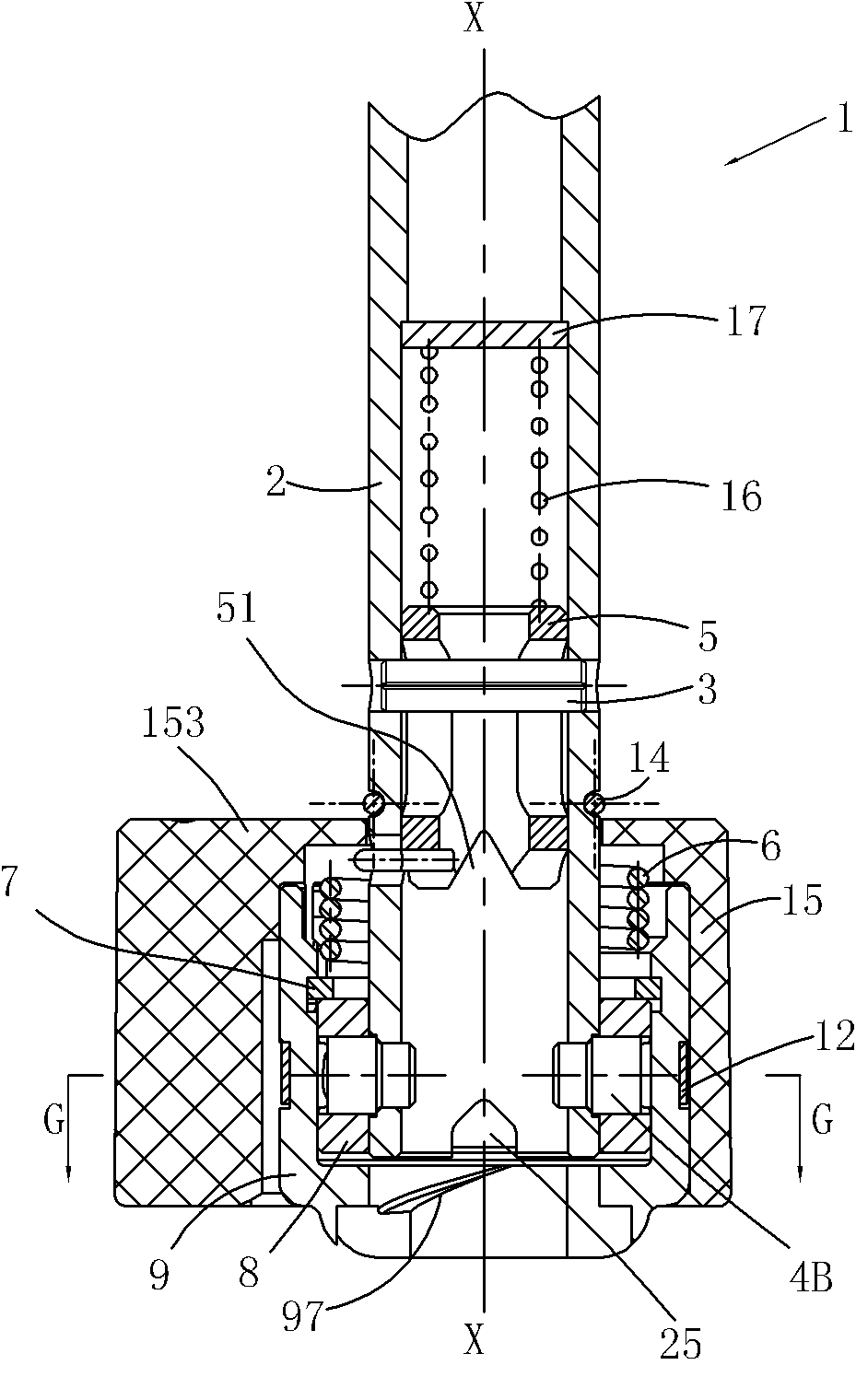

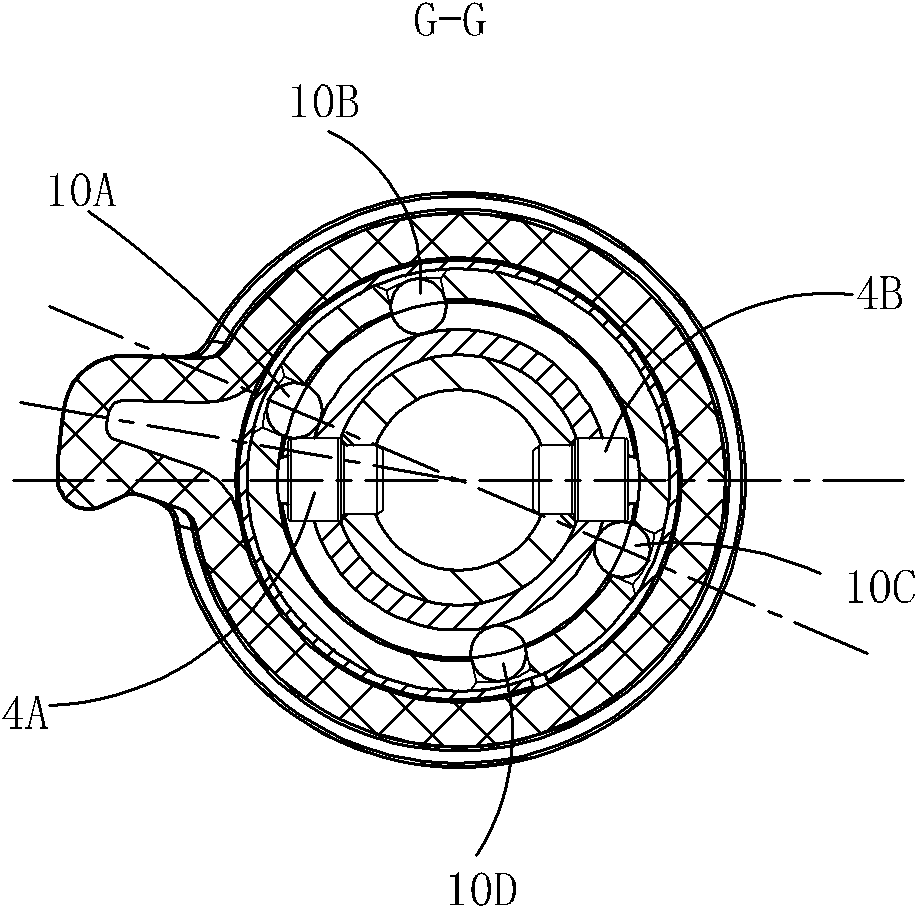

[0043] refer to Figure 1 to Figure 3 , this embodiment discloses a saw blade clamping device 1 suitable for a jigsaw, the saw blade clamping device 1 is arranged inside the casing (not shown in the figure) of the jigsaw and partly extends out of the casing, with Clamp the saw blade 13 and drive the saw blade 13 under the driving of the motor (not shown in the figure) figure 2 The axis X-X of the shown reciprocating rod reciprocates in order to perform cutting work, and the saw blade 13 can be released to replace the saw blade 13 .

[0044] The saw blade clamping device 1 mainly includes a locking rod. The locking rod in this embodiment includes a reciprocating rod 2 and a connecting ring 8 sleeved on the reciprocating rod. Connecting end 20; a locking assembly that is sleeved on the outside of the connecting end 20 of the reciprocating rod saw blade to clamp the saw blade 13 on the connecting end 20 of the reciprocating rod saw blade, and the locking assembly can rotate rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com