Gasification oil burner

A gasifier and burner technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of large atomization particle size, insufficient combustion, waste of energy, etc., and achieve high combustion efficiency, low cost, and high combustion effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

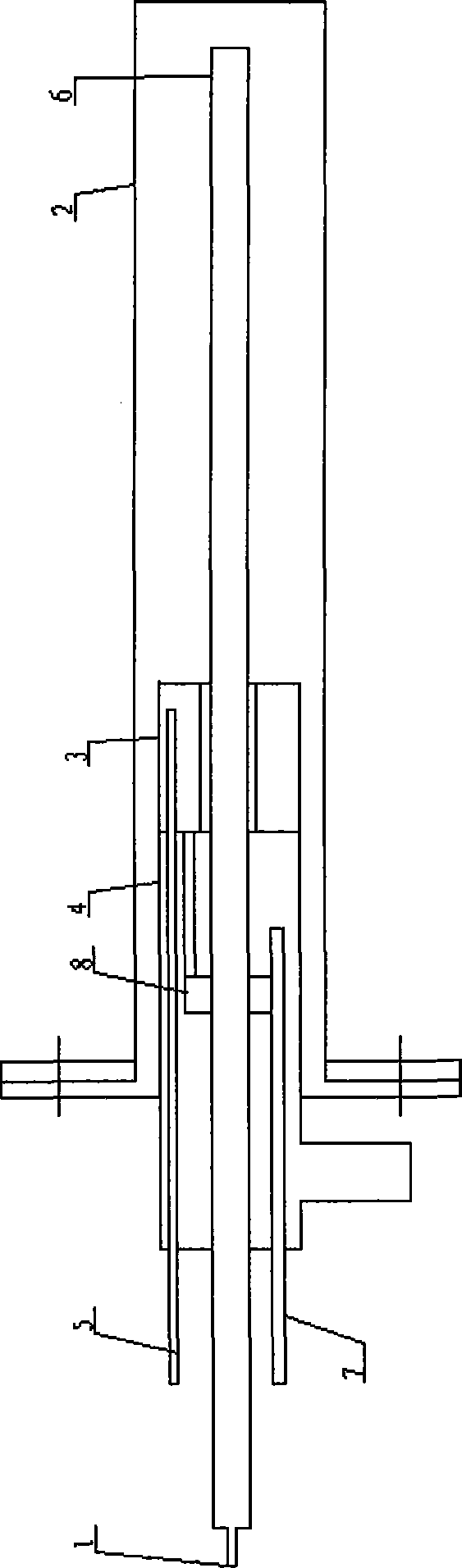

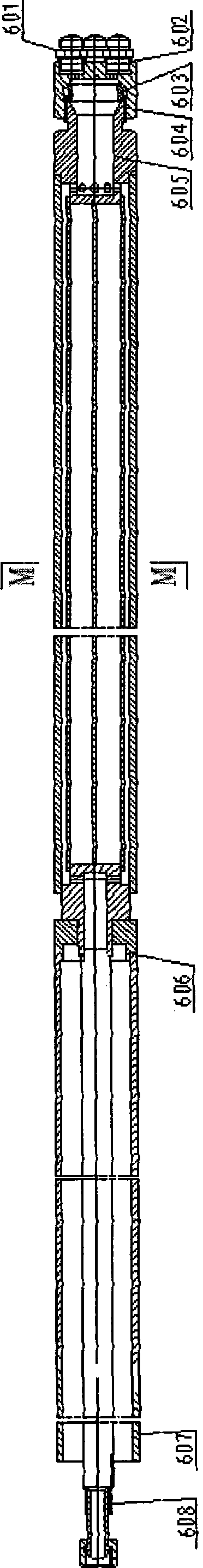

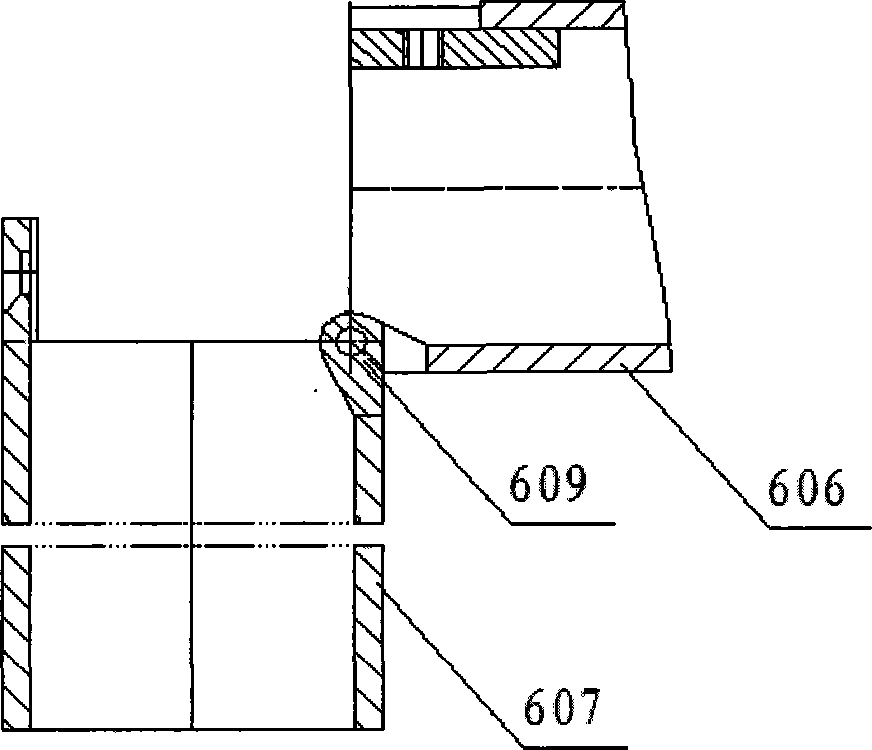

[0032] exist figure 1 Shows the gasification oil burner structure according to one embodiment of the present invention. like figure 1 As shown, the gasification oil burner includes a first-stage gasification flame generator, and the first-stage gasification flame generator includes a gasifier 3, an air distribution tube 4, a gasifier oil inlet pipe 5, an atomizing nozzle 8, Connect gasifier 3 with oil pipe of atomizing nozzle 8, and ignition gun 7. The gasification flame generator of the first stage can of course also consist of only these components. The gasification oil burner can also include a gasification oil gun 6 and a gasification oil gun inlet pipe 1, which constitute a second-stage gasification flame generator.

[0033] The vaporizer 3 is arranged inside the air distribution cylinder 4, preferably connected with the air distribution cylinder 4 as a whole. The gasifier fuel inlet pipe 5 is connected to the gasifier 3 for delivering fuel to the gasifier 3 . The at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com