Twist lock device for container hanging tool

A container spreader and twist lock technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of container falling off, hanging boxes, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

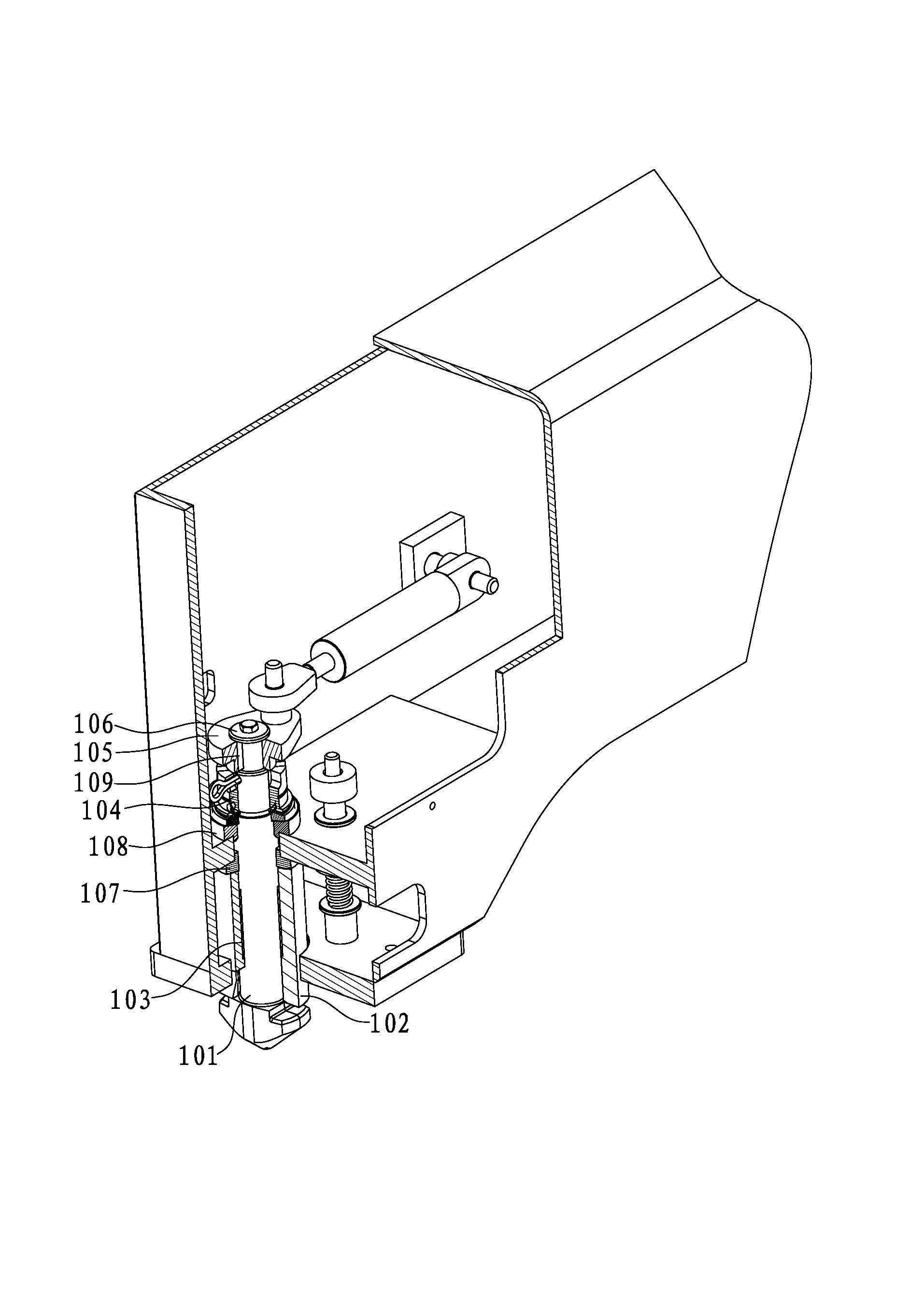

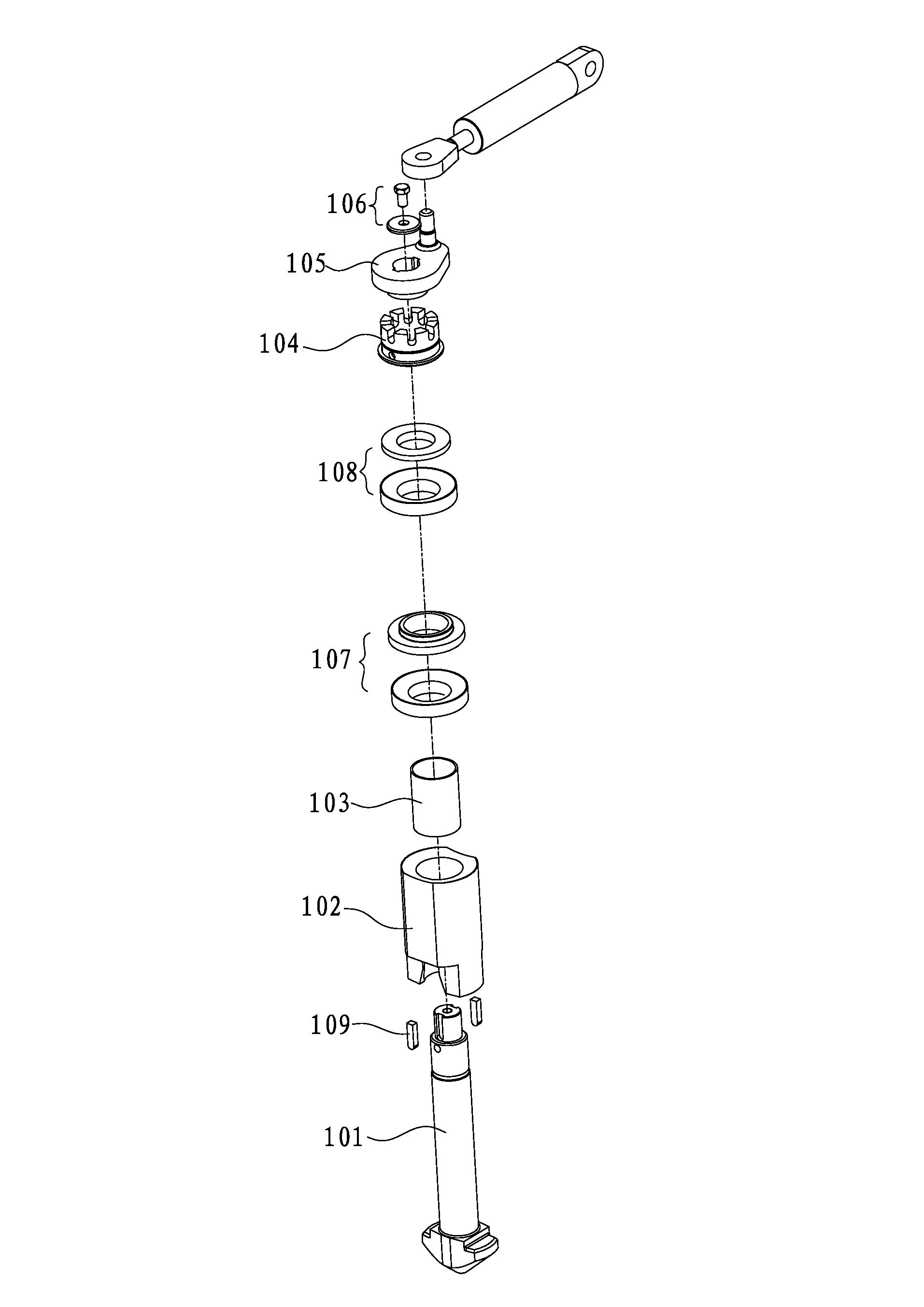

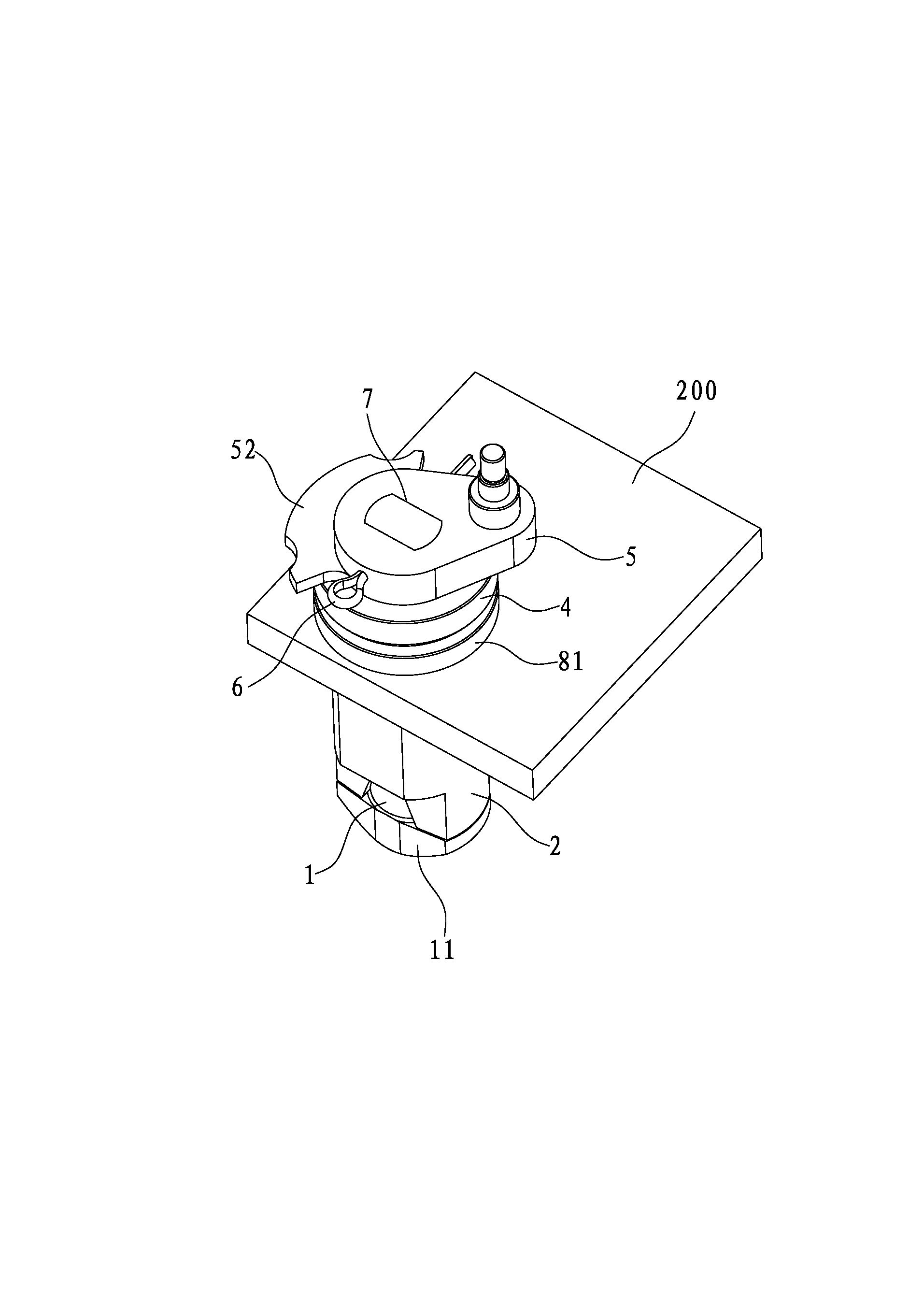

[0047] Such as figure 2 and Figure 2AAs shown, it is the first embodiment of the twist lock device of the present invention related to a container spreader. The turn lock device is installed on the support plate 200 of the container spreader. The turn lock device includes a turn lock pin 1, a guide bushing 2. Lubricating bushing 3, turn lock nut 4, turn handle 5 and anti-loosening member 6. The turn lock pin 1 is a core component that directly interacts with the container, and a hook 11 is formed at its lower end; the upper end of the turn lock pin 1 From bottom to top, it runs through the guide bush 2, the lubricating bush 3, the support plate 200, the turn lock nut 4 and the turning handle 5. The turn lock pin 1 has an external thread 12, through which the turn lock nut 4 can The internal thread 41 cooperates, and the anti-loosening part 6 is fixedly connected with the rotating lock pin 1 and the rotating handle 5, and the lubricating bush 3 is embedded in the inner hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com